Gluing device capable of cleaning dust on surface of adhesive tape for adhesive tape production

A technology of gluing device and adhesive tape, which is applied to the device, cleaning method, utensil, coating and other directions of coating liquid on the surface, can solve the problems of affecting the adhesiveness of adhesive tape, affecting the quality of finished products, easily contaminated with dust, etc. The effect of uniform glue, improving the quality of the finished product, and reducing the exposure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

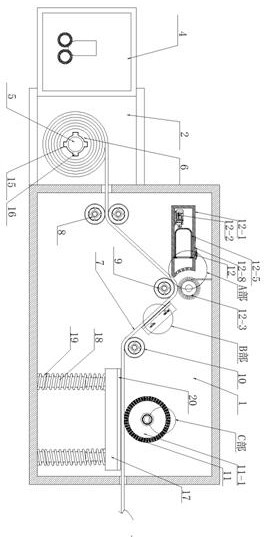

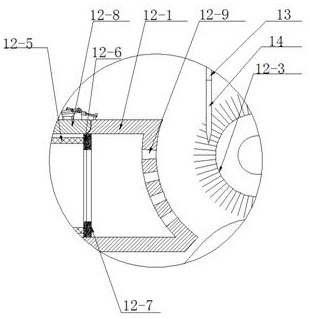

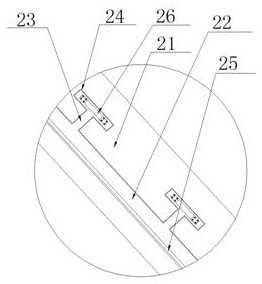

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] see as Figure 1-Figure 8Shown, the technical scheme that this specific embodiment adopts is: it comprises No. 1 box body 1, No. 2 box body 2, No. 1 box door 3, No. 2 box door 4; No. 2 box body 2 is welded, No. 1 box body 1 and No. 2 box body 2 are both hollow structures with front openings, and the opening ends of the front sides of No. 1 box body 1 and No. The No. 1 box door 3 and the No. 2 box door 4 are arranged to rotate with the bolt, and the No. 1 box door 3 and the No. 2 box door 4 are fixedly connected to the front side walls of the No. 1 box body 1 and the No. 2 box body 2 through a hasp respectively; It also includes a dust cleaning mechanism 12, a gluing mechanism 11, a rotating shaft 5, a discharge roller 6, a No. 1 guide roller 8, a No. 2 guide roller 9, and a No. 3 guide roller 10; There is a rotating shaft 5, and the rear end of the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com