Multi-stage vibration reduction suspension structure

A suspension and hose technology, used in power units, jet propulsion units, internal combustion propulsion units, etc., can solve the problems of easy damage, single vibration reduction means, poor vibration reduction effect, etc., and achieve good vibration reduction effect and vibration reduction. Rich means to solve the effect of high high frequency dynamic stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

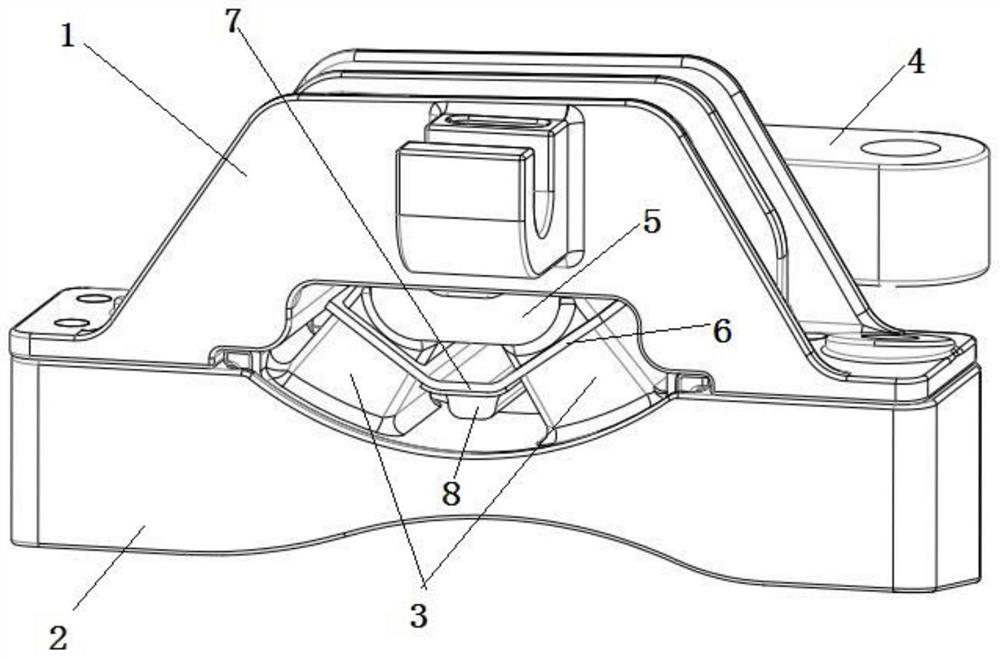

[0024] Such as figure 1 As shown, a multi-stage vibration-damping suspension structure includes an upper bracket 1, a lower bracket 2, a main spring rubber and a support arm 4 for connecting the engine assembly, and the main spring rubber includes a bracket for fixing the support arm The main spring inner frame 5 and two main spring bases 3 symmetrically arranged on both sides of the main spring inner frame, the middle part of the main spring rubber is provided with a vulcanized middle frame, and the vulcanized middle frame includes two left and right symmetrically arranged side plates 6 and the bottom plate 7 located between the side plates 6, the side plate 6 is embedded in one end of the main spring base 3 adjacent to the inner frame 5 of the main spring, and a columnar spacer rubber block 8 is provided under the bottom plate 7, the main spring There is a first gap between the spring inner frame 5 and the side plate 6 , and there is a second gap between the limiting rubber ...

Embodiment 2

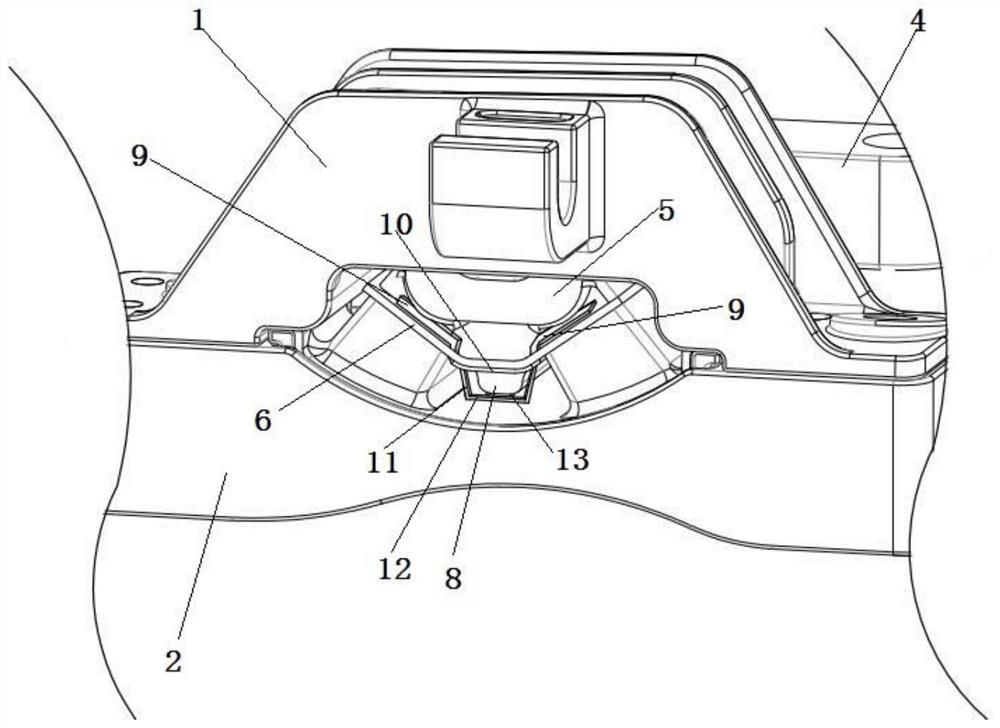

[0027] Based on Example 1, such as figure 2As shown, a first hose 9 is provided between the main spring inner frame 5 and the two side plates 6, and a second horizontal hose 10 is provided between the bottom plate 7 and the stop rubber block 8 , the second hose 10 is located between the two first hoses 9 and communicates with the first hose 9, and the two ends of the first hose 9 and the second hose 10 are connected to form a closed cavity. Hydraulic oil is provided inside the first hose 9 and the second hose 10 . Both sides of the second hose 10 are provided with a vertically arranged third hose 11, the upper end of the third hose 11 is connected to the bottom of the second hose 10 and a rubber valve (not shown in the figure) is provided at its upper port. , the rubber valve used will open when the rubber valve is squeezed by the hydraulic oil, and the rubber valve will close when there is no force), the fourth hose 12 placed horizontally is arranged under the limit rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com