Engine

A technology of engine and transmission wheel, which is applied in the direction of engine components, combustion engines, engine starting, etc., and can solve problems such as difficult control, easy flameout, and large supercharged structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

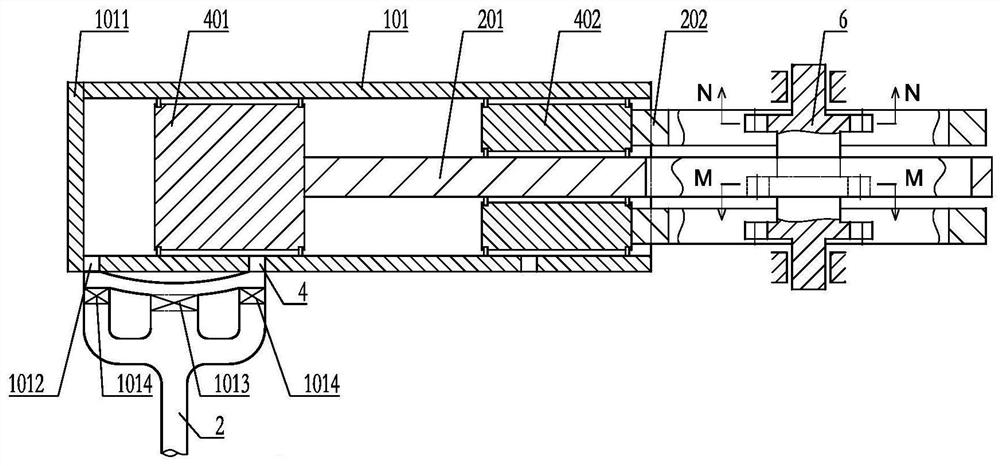

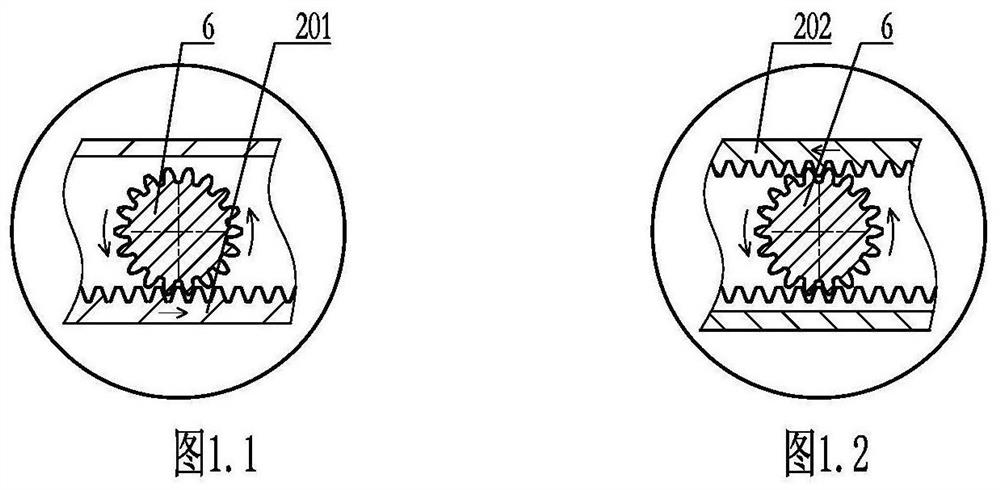

[0057] an engine such as figure 1As shown, it includes a cylinder A 101, a reciprocating structure A 201 and a reciprocating structure B 202, a piston A 401 is set on the reciprocating structure A 201, and a piston B is set on the reciprocating structure B 202 402, the piston A 401 and the piston B 402 are arranged on top of each other in the cylinder A 101, and the reciprocating structure A 201 is partially arranged in the cylinder A 101 and passes through the piston B 402. The gas distribution port 4 is set on the cylinder A 101, the reciprocating structure A 201 and the reciprocating structure B 202 are set in reverse linkage through the transmission wheel 6, and the cylinder A 101 includes a cylinder A end 1011, so The piston A 401, the side wall of the cylinder A 101 and the end 1011 of the cylinder A form a volume change space, and a gas conduction port A 1012 is set on the side wall of the cylinder A 101, and the gas conduction port A 1012 It is set in communication wi...

Embodiment 2

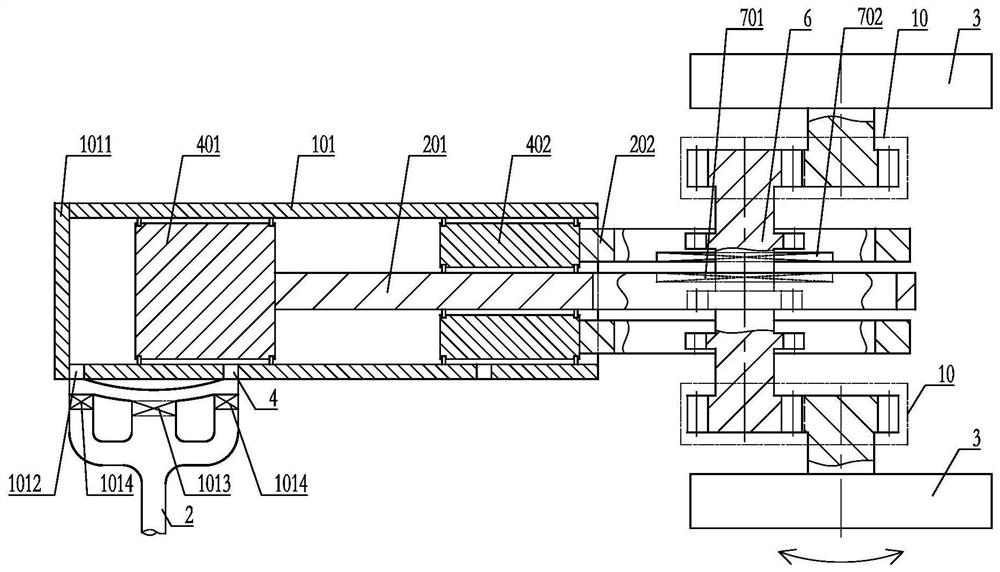

[0064] an engine such as figure 2 As shown, the difference with Embodiment 1 is that on the basis of Embodiment 1, the two ends of the transmission wheel 6 are further set through the transmission unit 10 and the mass of inertia 3 respectively, and the reciprocating structure A201 A magnetic zone A 701 is set on the reciprocating structure B 202, and a magnetic zone B 702 is set on the reciprocating structure B 202. The magnetic zone A701 and the magnetic zone B 702 are mutually magnetically arranged.

[0065] As an alternative embodiment, in Embodiment 2 of the present invention, the magnetic force interaction setting between the magnetic force zone A 701 and the magnetic force zone B 702 and the magnetic force zone X can also be selectively selected.

[0066] As a transformable embodiment, in embodiment 2 of the present invention and its transformable embodiments, it is preferable to make the transmission unit 10 as a speed change mechanism or as a torsion bar during specif...

Embodiment 3

[0069] an engine such as image 3 As shown, the difference from Embodiment 1 is that on the basis of Embodiment 1, the transmission wheel 6 is further configured to be driven by the elastic structure body 13 and the moment of inertia body 3 .

[0070] As a transformable embodiment, the transformable embodiment of the embodiment 1 of the present invention can further selectively make the transmission wheel 6 and the moment of inertia body 3 drive and set through the elastic structure body 13 . Preferably, the elastic structure 13 is a torsion bar. For specific implementation, it can be implemented with reference to the implementation manner of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com