Engine

An engine, the same technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve problems such as non-rotating power and easy engine flameout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

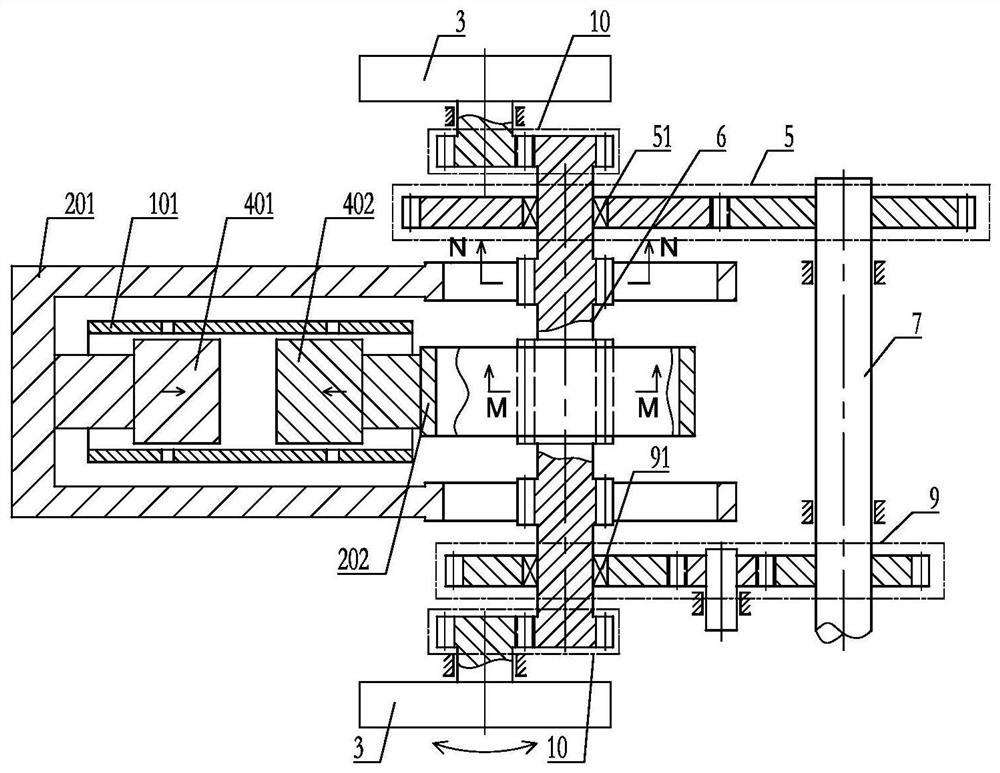

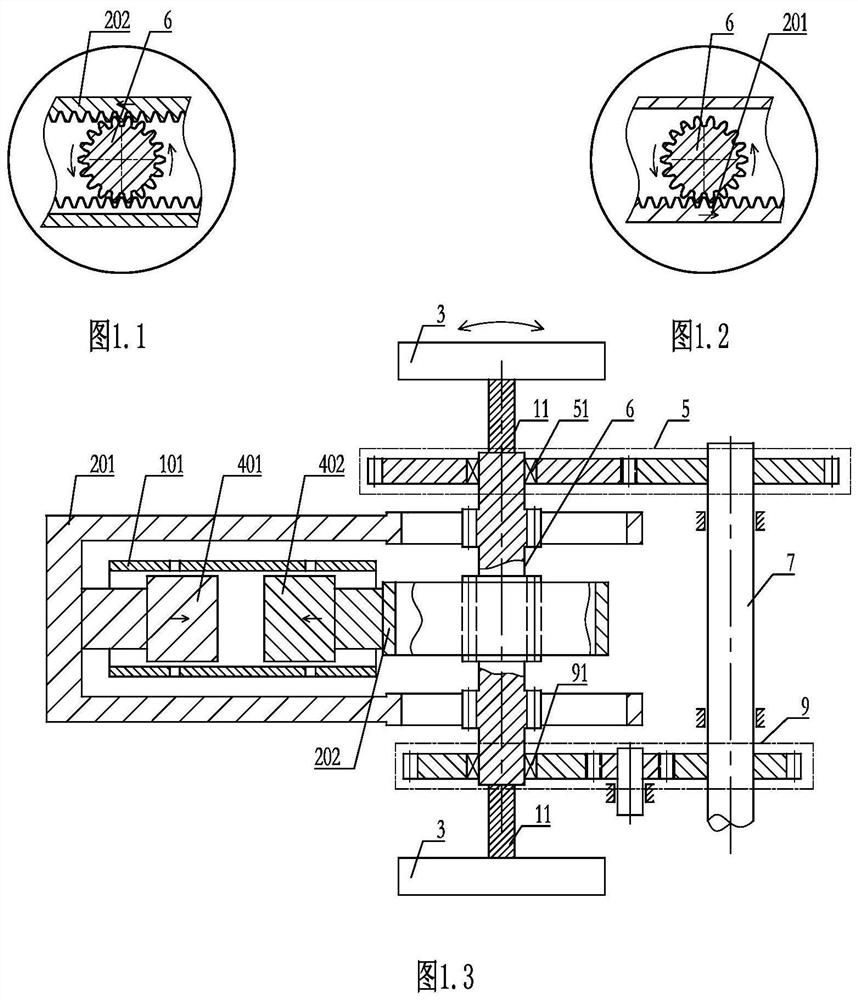

[0042] an engine such as figure 1 As shown, it includes a cylinder A101, a reciprocating structure A 201, a reciprocating structure B202, a moment of inertia body 3 and a rotating wheel 6. A piston A 401 is arranged on the reciprocating structure A 201, and a piston A 401 is set on the reciprocating structure A 201. A piston B 402 is arranged on the body B 202, and the piston A 401 and the piston B 402 are arranged on top of each other in the cylinder A101, and the reciprocating structure A 201 is arranged outside the cylinder A101. A gas distribution port is set on A101, and the reciprocating structure A 201 and the reciprocating structure B 202 are set in reverse linkage through the transmission wheel 6, and the two sides of the transmission wheel 6 are connected to the transmission wheel 6 through the speed change mechanism 10 respectively. The moment of inertia body 3 is set in transmission, the transmission wheel 6 is set to the power shaft X 7 through the transmission li...

Embodiment 2

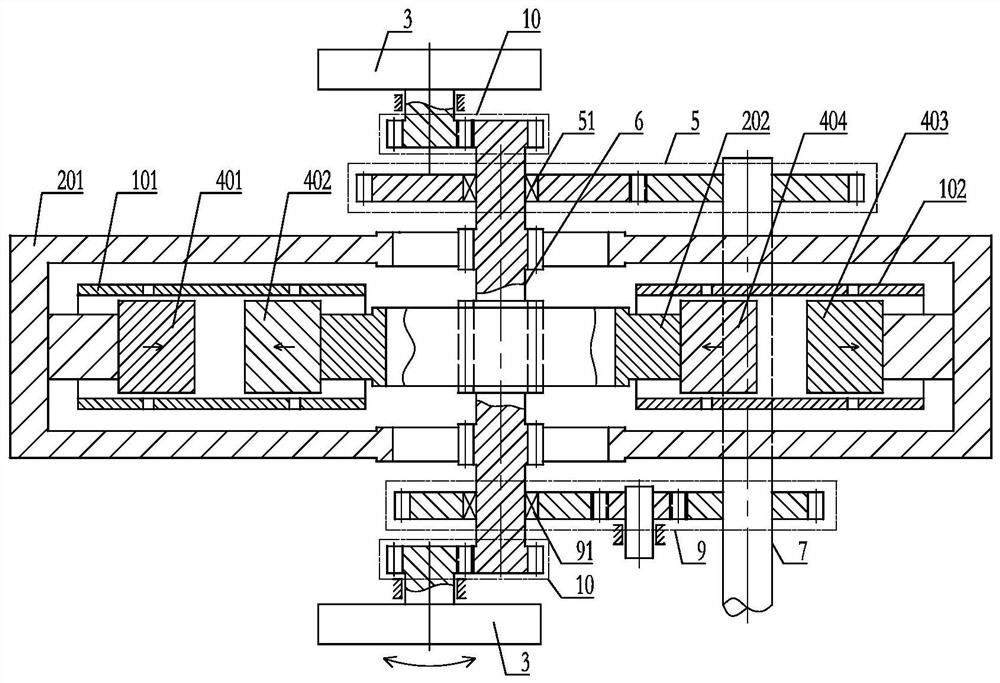

[0053] an engine such as figure 2 As shown, it includes a cylinder A101, a reciprocating structure A 201, a reciprocating structure B202, a cylinder B102, a moment of inertia body 3 and a rotating wheel 6, and a piston A 401 is set on the reciprocating structure A 201. A piston B 402 is arranged on the reciprocating structure B 202, and the piston A 401 and the piston B 402 are arranged in the cylinder A101 facing each other, and the reciprocating structure A 201 is arranged outside the cylinder A101. A gas distribution port is set on the cylinder A101, a piston C 403 is set on the reciprocating structure A 201, a piston D 404 is set on the reciprocating structure B 202, the piston C 403 and the piston D 404 The top is arranged in the cylinder B102, the reciprocating structure A 201 is arranged outside the cylinder B102, and a gas distribution port is set on the cylinder B102, the reciprocating structure A 201 and the reciprocating structure The body B 202 is set in reverse ...

Embodiment 3

[0067] an engine such as image 3 As shown, it includes a cylinder A101, a reciprocating structure A 201, a reciprocating structure B202, a moment of inertia body 3 and a rotating wheel 6. A piston A 401 is arranged on the reciprocating structure A 201, and a piston A 401 is set on the reciprocating structure A 201. A piston B 402 is set on the body B 202, the piston A 401 and the piston B 402 are arranged on top of each other in the cylinder A101, and the reciprocating structure A 201 is set in the cylinder A101 and passes through the piston B 402, a gas distribution port is set on the cylinder A101, the reciprocating structure A 201 and the reciprocating structure B 202 are set in reverse linkage through the transmission wheel 6, and the transmission wheel 6 and the rotating Inertia body 3 transmission settings, the transmission wheel 6 is set to the power shaft X 7 through the transmission route A5, the transmission wheel 6 is set to the power shaft X 7 through the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com