Steel plate blank heat preservation vehicle

A technology for thermal insulation vehicles and steel slabs, applied in the field of thermal insulation vehicles of steel slabs, can solve the problems of high temperature waste heat not being recycled, energy waste, etc., and achieve the effects of preventing temperature loss, reducing costs, and reducing heating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

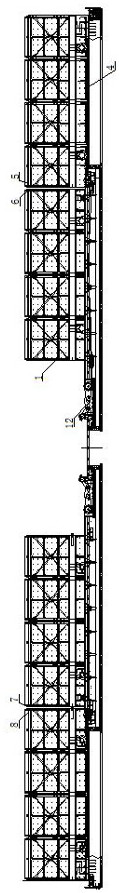

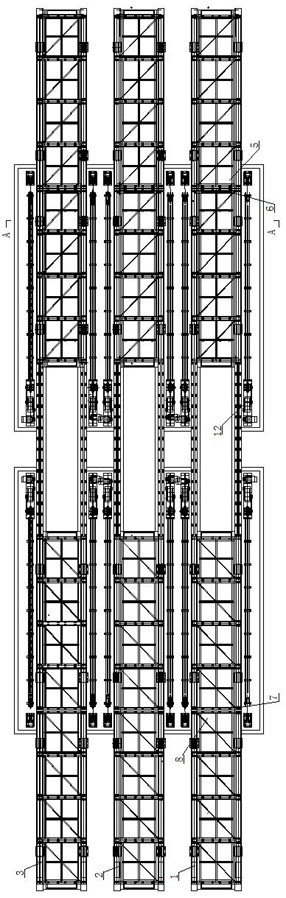

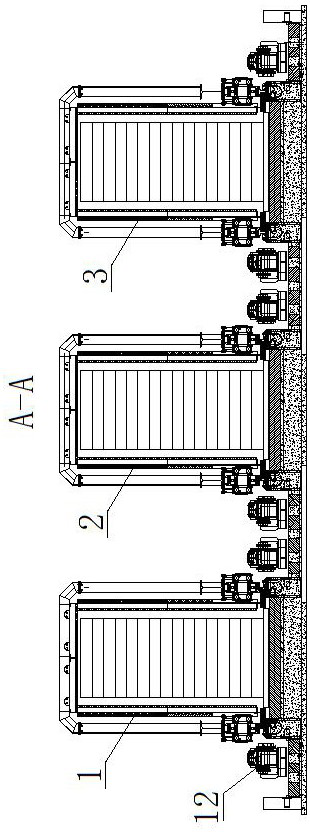

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

[0049] see figure 1 , figure 2 , image 3 , the present embodiment is a steel slab heat preservation car, the heat preservation car is covered on the steel slabs of the slab stacks, and each slab stack is stacked with 16 layers of steel slabs, and the slab stacks (not shown) are 3 There are 4 rows in each row, two slab stacks form a group, and each slab stack is provided with an insulated car, and three rows of insulated cars with the same structure are provided, which are the first row of insulated cars 1 and the second row of insulated cars. Two rows of insulation cars 2 and the third row of insulation cars 3. Guide rails 4 are installed on both sides of each column of slab stacks, and each column of thermal insulation vehicles is placed on the guide rails 4. Each column of thermal insulation vehicles is provided with four single thermal in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com