Water-turbine generator set tight bushing disassembly device and disassembly method thereof

A technology of generator set and disassembly device, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of affecting the sealing effect, jamming of the casing and the main shaft, damage to the bushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

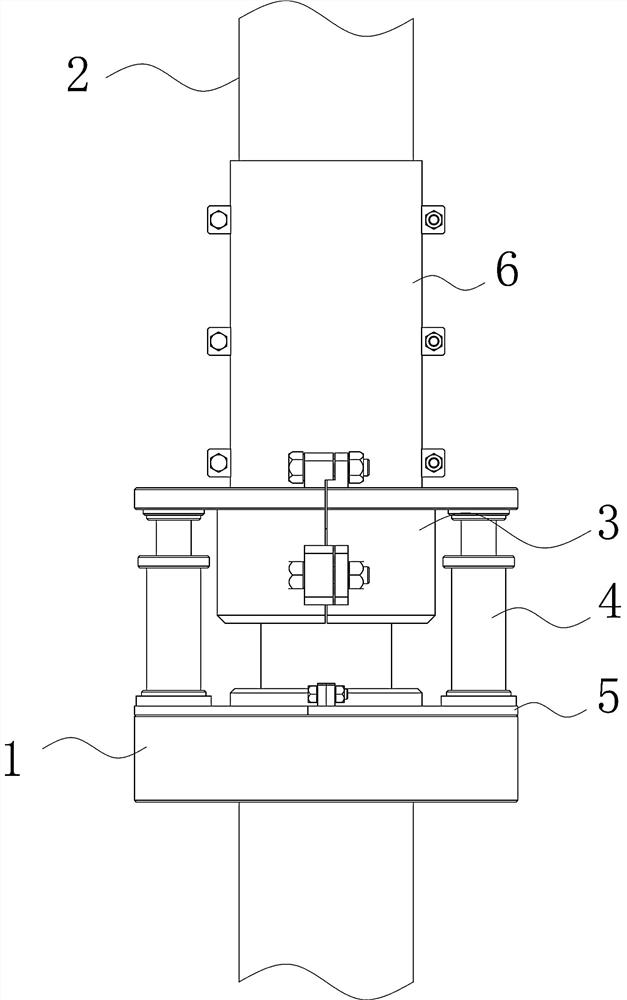

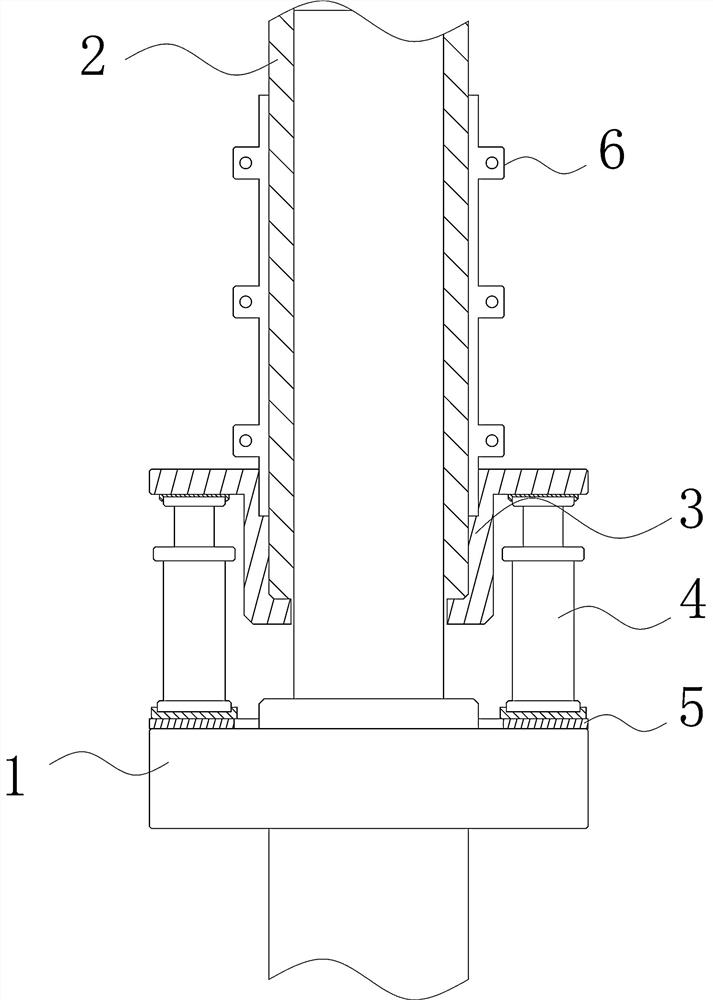

[0042] like Figure 1~14 As shown in the figure, a tight bushing removal device for a hydroelectric generator set includes a top sleeve 3, the top sleeve 3 includes two semicircular sleeve plates, and the bottom of the two semicircular sleeve plates is sleeved on the end of the sleeve 2 , the upper outer circumference of the cover plate is provided with a protruding disk body, and a bottom plate 5 is provided under the top cover 3. The hydraulic cylinder 4, the piston end of the hydraulic cylinder 4 leans against the disc body at the upper end of the top sleeve 3 . With this structure, the hydraulic cylinder 4 is used to push the top sleeve 3, and the top sleeve 3 drives the bush to rise to achieve the purpose of disassembly, and the lower part of the top sleeve 3 wraps the end of the bush 2 to protect the end of the bush 2 from pressure. The utility model has the advantages of convenient disassembly, improved work efficiency, simple structure, convenient use, and is suitable...

Embodiment 2

[0052] Further illustrate in conjunction with embodiment 1, as Figure 1~14 Shown: The method includes:

[0053] Put the first circular plate 501 and the second circular plate 502 on the boss position of the main shaft 1 of the air supply valve and splice them into an annular bottom plate 5 , and use a spirit level to adjust the balance of the bottom plate 5 .

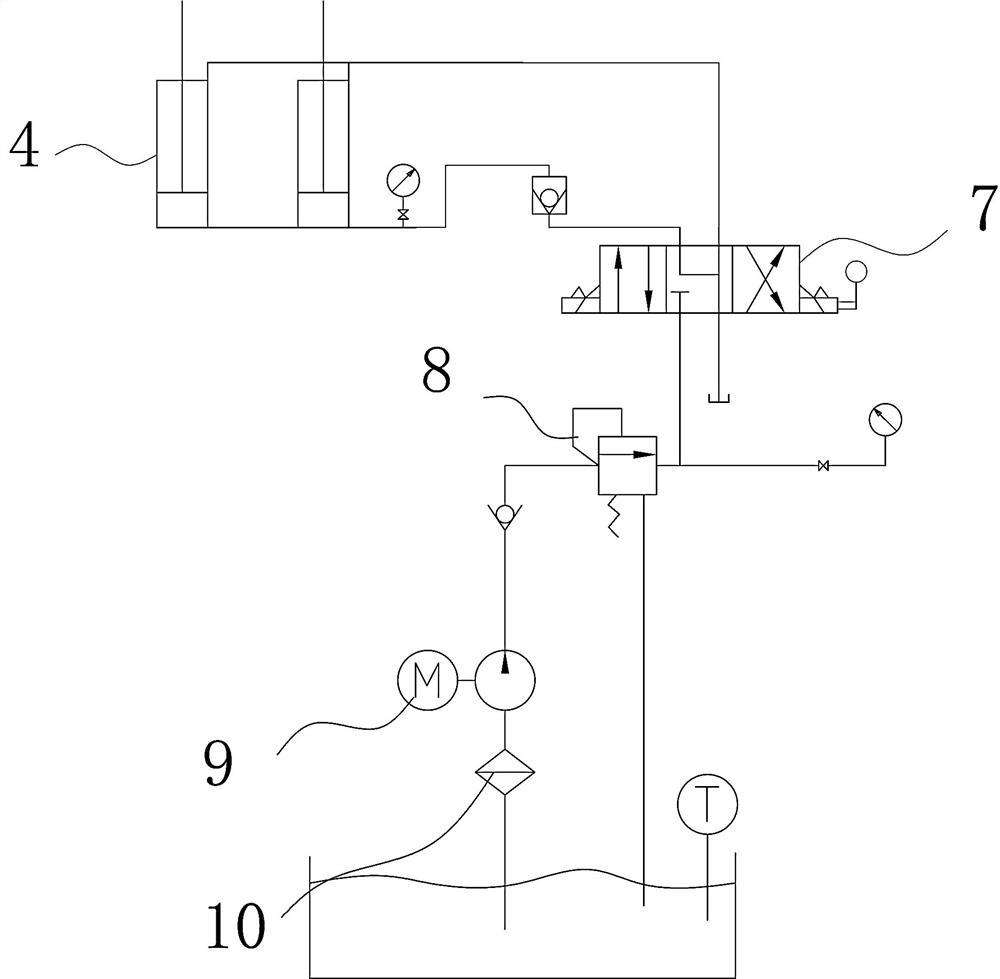

[0054] The hydraulic cylinder 4 is placed in the placement groove 503 of the bottom plate 5 , and the hydraulic pipe is used to communicate with the electromagnetic reversing valve 7 , and the electromagnetic reversing valve 7 communicates with the hydraulic pump 9 .

[0055] Regulate the electromagnetic reversing valve 7 and the hydraulic pump 9 to make the two hydraulic cylinders 4 retract to the bottom and keep the piston ends of the two hydraulic cylinders 4 on the same plane.

[0056] The first set plate 301 and the second set plate 302 are set on the end of the bushing 2, the bosses at the bottom of the first se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap