Punching device used for folding stool machining

A technology of punching device and mounting plate, applied in fixed drilling machine and other directions, can solve the problems of difficult fixing of wood and complicated operation process, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

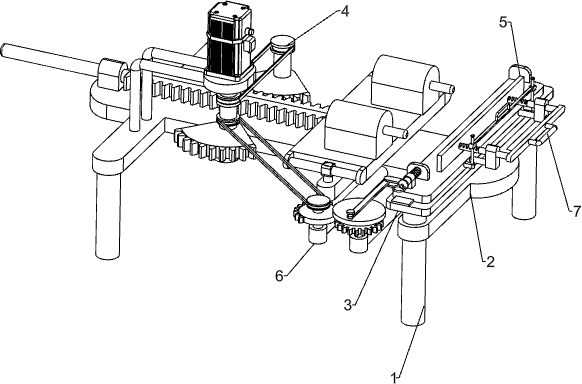

[0048] A kind of perforating device for maza processing, such as figure 1 As shown, it includes a base 1, a mounting plate 2, a slide rail plate 3, a punching mechanism 4, and a clamping mechanism 5. The bottom of the mounting plate 2 is provided with a base 1, and the upper right part of the mounting plate 2 is connected with a slide rail. Plate 3, the upper side of mounting plate 2 is connected with punching mechanism 4, and punching mechanism 4 is positioned at the left side of slide rail plate 3, and the upper side of slide rail plate 3 is slidably connected with clamping mechanism 5.

[0049] When the staff needs to punch holes in the wood for making Maza, the staff can pull the clamping mechanism 5 forward, place the wood on the clamping mechanism 5, and loosen the clamping mechanism 5, so as to clamp and fix the wood The purpose of starting the punching mechanism 4, the punching mechanism 4 moves to the right, and the wood is punched. After the operation, close the punc...

Embodiment 2

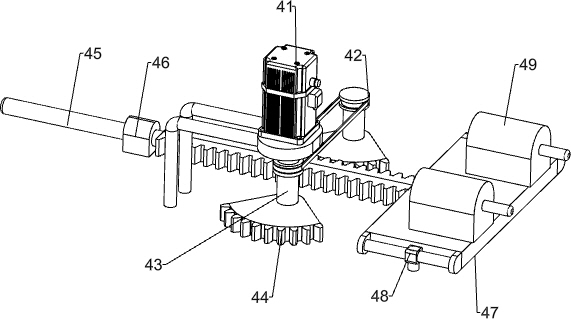

[0051] On the basis of Example 1, such as figure 2 As shown, the punching mechanism 4 includes a motor 41, a first transmission assembly 42, a first rotating shaft 43, a sector gear 44, a rack bar 45, a first sliding sleeve 46, a first sliding plate 47, a second sliding sleeve 48 and Hitting machine 49, the left side of the top of the mounting plate 2 is connected to the motor 41 through the mounting bracket, the front and rear sides of the top of the mounting plate 2 are rotatably connected to the first rotating shaft 43 through the bearing seat, the first rotating shaft 43 at the front and the output shaft of the motor 41 The first transmission assembly 42 is wound between the first rotating shafts 43, the sector gear 44 is connected to the lower part of the first rotating shaft 43, and the first sliding sleeve 46 is connected to the upper side of the left part of the mounting plate 2, and the inside of the first sliding sleeve 46 The rack bar 45 is slidingly connected, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com