Vibration device for reinforcing coagulability of concrete in concrete mold production

A vibration device, concrete technology, applied in the direction of the supply device, manufacturing tools, ceramic molding machines, etc., to achieve the effect of avoiding accumulation into blocks, increasing the strength in the later stage, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

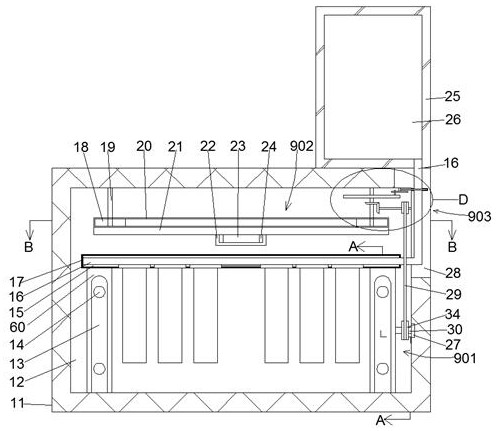

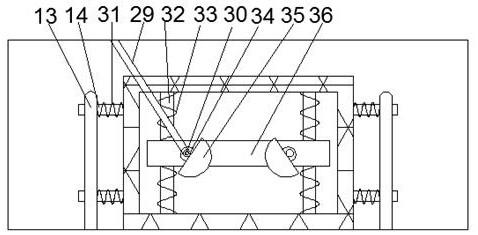

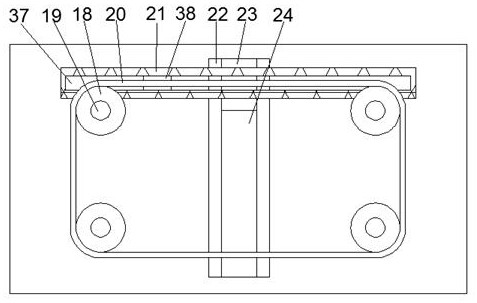

[0017] Combine below Figure 1-Figure 6 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0018] The present invention relates to a vibrating device for strengthening the solidification of concrete in the production of concrete molds. It is mainly used in the production of concrete molds to vibrate the concrete in the mold and automatically sprinkle fly ash. The present invention will be further described in conjunction with the accompanying drawings Explanation: A vibrating device for strengthening concrete coagulation in the production of concrete molds according to the present invention includes a working box 11, a cavity 12 is arranged in the working box 11, and left and right sides are fixed on the inner wall of the lower side of the cavity 12. Two symmetrical su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com