Construction method for pile-anchor support of spiral cage core anchor rod

A construction method and anchor pile technology, which is applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problem of poor tensile capacity of anchor support, poor tensile performance of plain concrete, and ineffective anchor support. Meet the problems of engineering construction and achieve the effect of increasing the ultimate load, improving the pull-out resistance and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

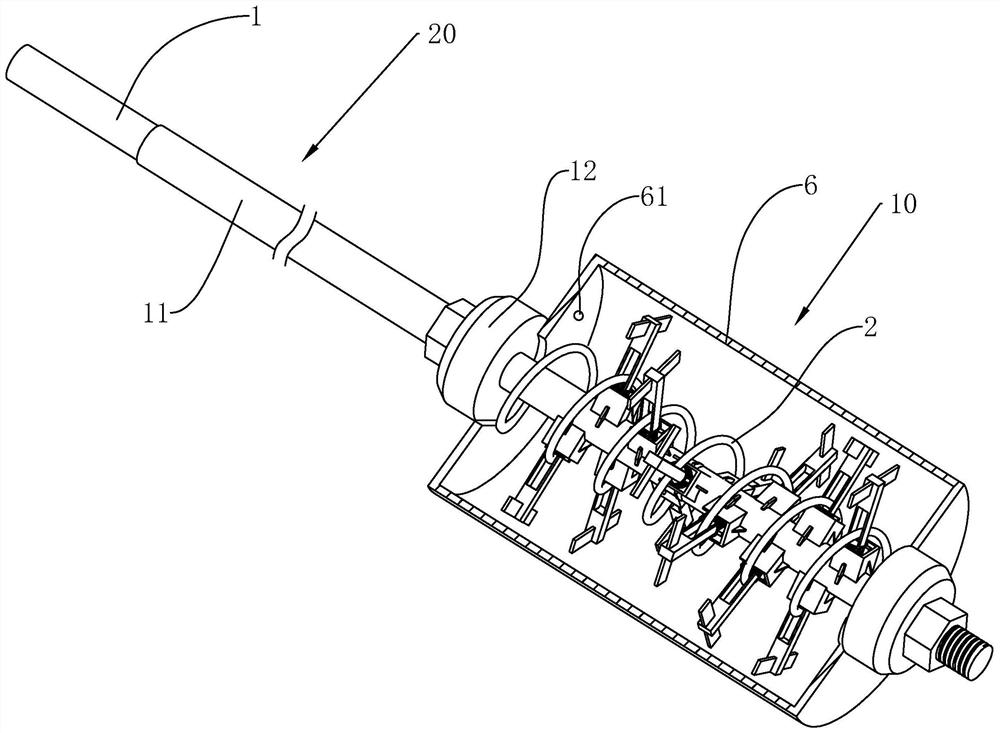

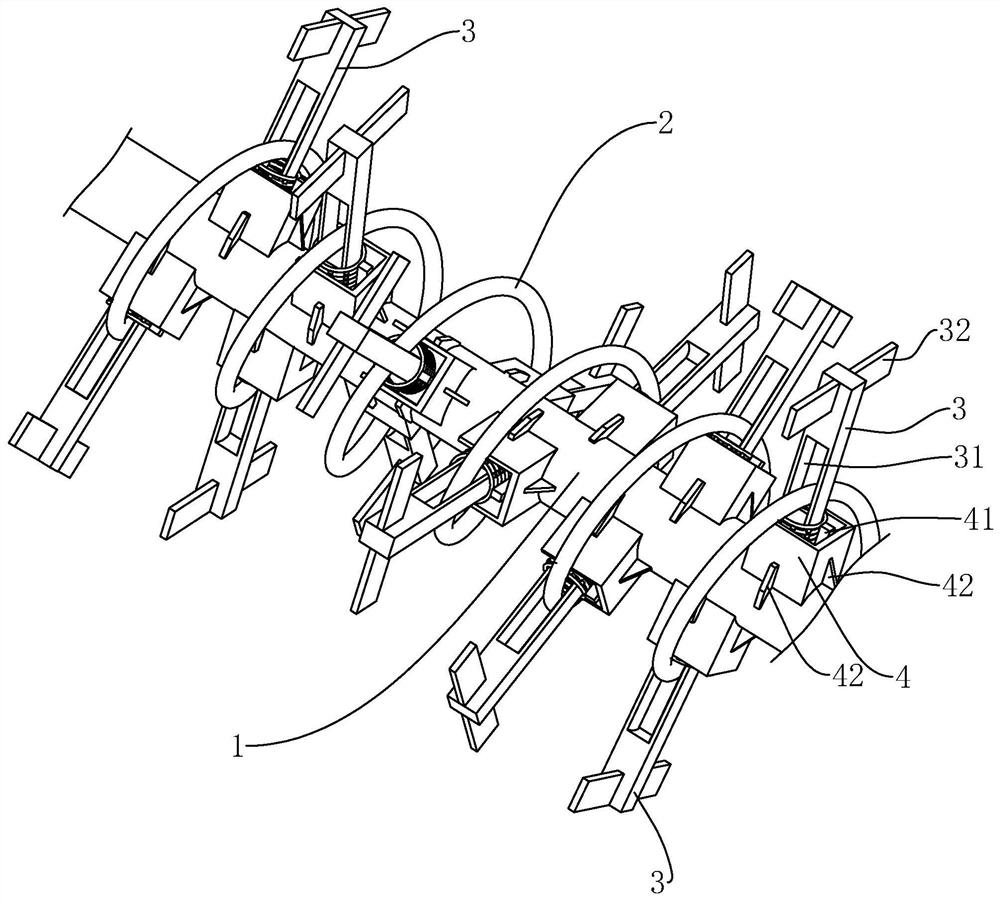

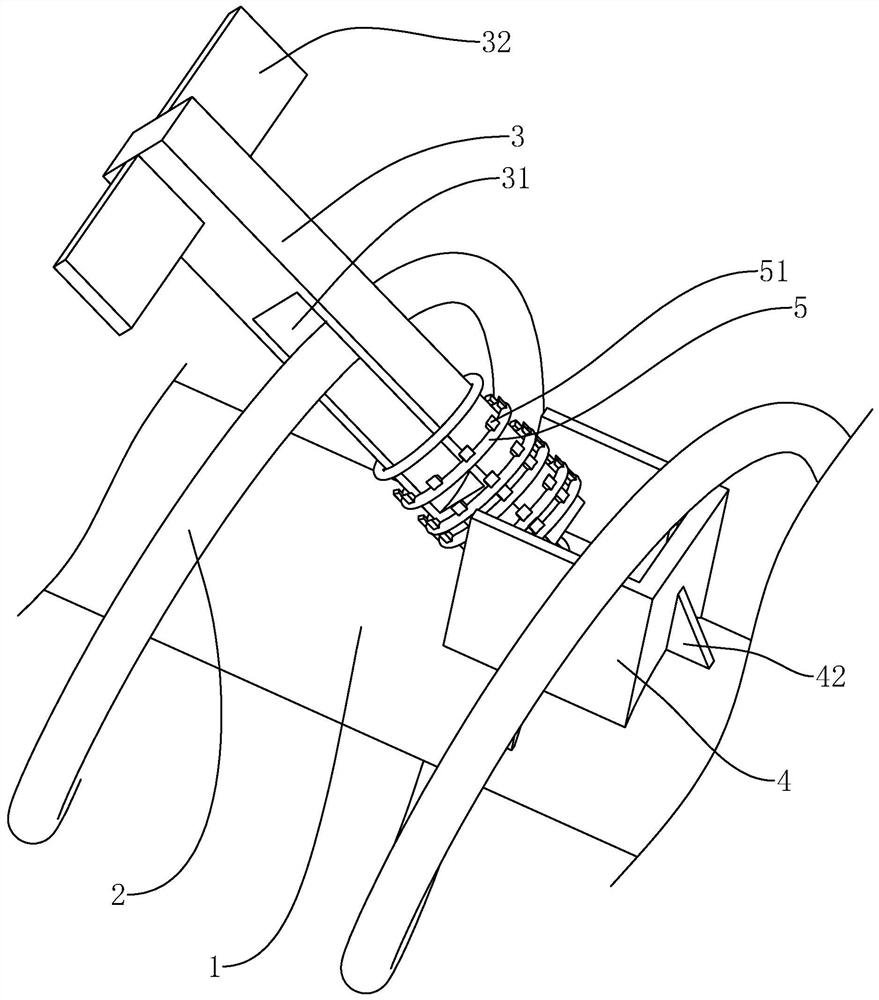

[0056] Embodiment 1: as figure 1 As shown, it is an anchor rod structure disclosed by the present invention, which includes a rod body 1, the rod body 1 has a free section 20 and an anchoring section 10, wherein the free section 20 of the rod body 1 is provided with an anti-corrosion structure 11, and the anchoring section 10 of the rod body 1 is sleeved There are spiral ribs 2 , and the outer cover of the anchoring section 10 of the rod body 1 is provided with a bladder 6 , and the bladder 6 is provided with a grouting port 61 .

[0057] Such as figure 1 As shown, the spiral rib 2 and the rod body 1 are rotated around the axis of the rod body 1. The anchor section 10 is provided with two bearing bodies. The bearing body close to the free section 20 is named as the driving bearing body 12. Drive groove (not marked in the figure), one end of the spiral rib 2 is fixedly connected with the drive carrier 12, and the other end of the spiral rib 2 is in contact with another carrier...

Embodiment 2

[0062] Embodiment 2: be a kind of construction method of the spiral cage core bolt pile anchor support based on the anchor rod structure of embodiment 1, comprise the following steps:

[0063] S1. Construction preparations, including:

[0064] S1.1. Determine the construction plan, and prepare construction technical measures that meet the design specifications and process requirements;

[0065] S1.2. The technical research team goes deep into the construction site, investigates the actual situation on the site and the surrounding environment, consults the information, and reviews the drawings;

[0066] S1.3. Material preparation, labor preparation and tool preparation must meet the requirements.

[0067] S2. Determine the hole position, including:

[0068] S2.1. Carry out measurement and release according to the basic layout plan, record the process of setting out the wire; if the error of the hole position coordinates is within 50mm, determine the anchorage area, and detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com