A Construction Method of Shear Walls on Both Sides in a Narrow Space

A technology of narrow space and construction method, applied in formwork/formwork/work frame, on-site preparation of building components, connection of formwork/formwork/work frame, etc., can solve problems such as low efficiency of formwork support method , to achieve the effect of overcoming the difficulty of cleaning construction residues, flexible and adjustable spacing of the bearing plates, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

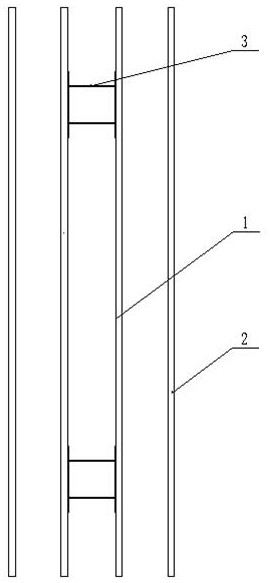

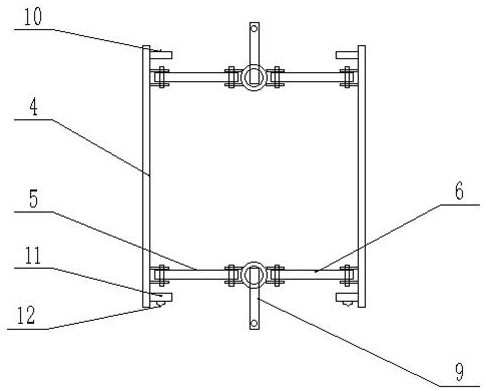

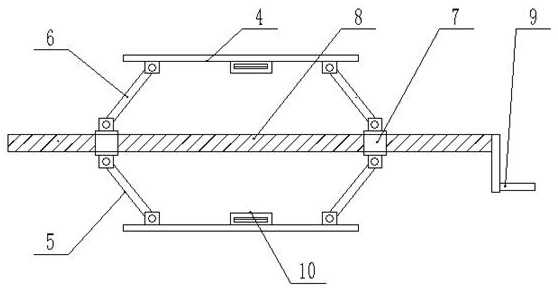

[0029] The reference signs in the drawings of the description include: inner template 1, outer template 2, support device 3, pressure bearing plate 4, left connecting rod 5, right connecting rod 6, nut seat 7, screw rod 8, rotating handle 9, positioning Board 10, positioning frame 11, laser emitter 12.

[0030] A construction method of shear walls on both sides of a narrow space in this specific embodiment comprises the following steps, A, first binding the steel bars of the shear walls, and then supporting the side forms of the shear walls on both sides of the construction joints or deformation joints , a plurality of pull screw rods 8 are horizontally set to limit and fix the outer formwork 2 of the two side molds, and the distance between the inner formwork 1 of the two side molds is the distance between the construction joint or the deformation joint; B, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com