IC chip appearance inspection module

A technology of appearance inspection and chips, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of inspection IC chip appearance inspection productivity cannot be improved, and the overall mechanism action increases, so as to reduce the cost of procurement and replacement , increase production capacity, and reduce the effect of up and down movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

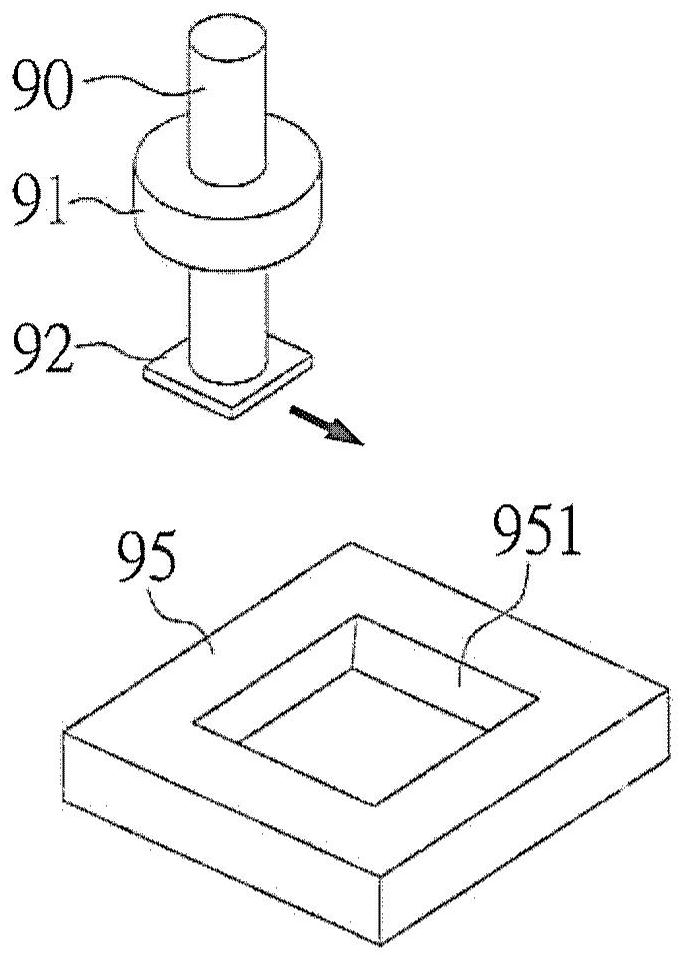

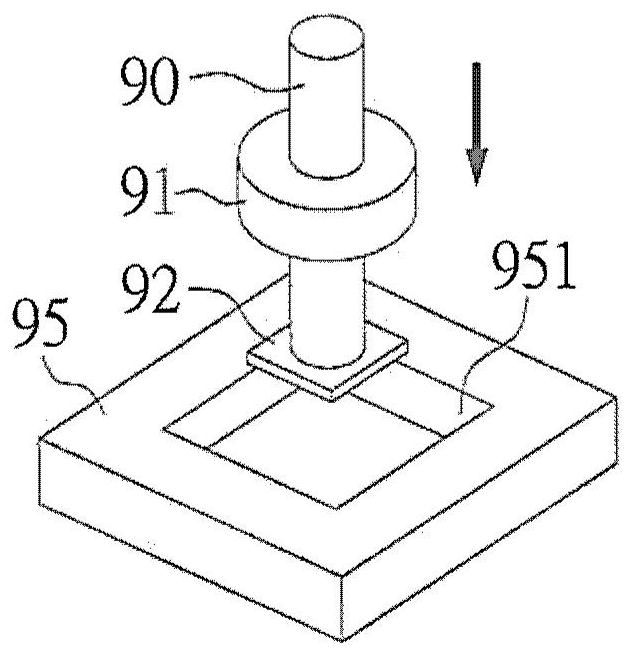

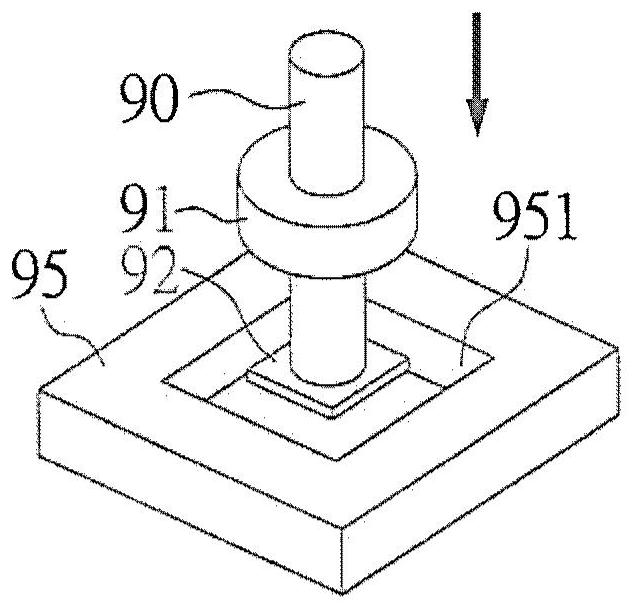

[0043] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, they are the perspective view of the IC chip appearance inspection module of the first preferred embodiment of the present invention, the perspective view of the IC chip appearance inspection module from another perspective, the perspective view of the nozzle steering mechanism and the perspective view of the optical IC inspection seat. The IC chip appearance inspection module 1 of this embodiment includes a machine table 10 , two optical IC inspection seats 20 , an imaging module 2 , a driving device and a nozzle steering mechanism 40 .

[0044] Such as figure 2As shown, the machine table 10 has a conveying unit 11, and devices such as two optical IC inspection seats 20, an imaging module 2 and a suction nozzle steering mechanism 40 are all arranged on the machine table 10, and the two optical IC inspection seats 20 is correspondingly arranged on the machine platform 10 . In addition, the suction no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com