In-situ shear apparatus

A shearing instrument, in-situ technology, used in instruments, scientific instruments, and testing the strength of materials by applying a stable shearing force. and other problems to achieve the effect of improving the detection speed and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

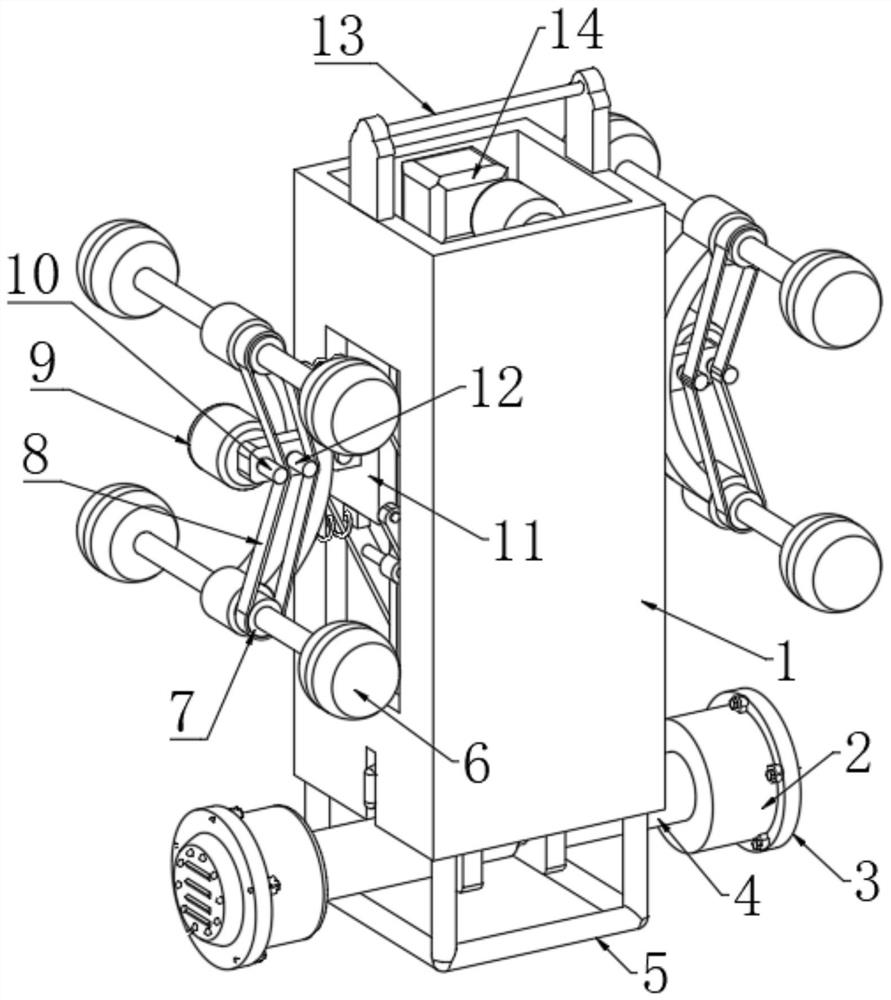

[0031] Refer to attached Figure 1-8, an in-situ shearing instrument, comprising a shell 1, a horizontal plate 15 and a mounting plate 20 are fixedly connected in the shell 1, through holes are opened on opposite sides of the shell 1, and there are connected in the two through holes Support plate 11, the side wall of support plate 11 is connected with walking mechanism, and walking mechanism comprises fixed plate 33, and the two ends of fixed plate 33 are all connected with rotating shaft through the second rolling bearing rotation, and the two ends of two rotating shafts are all fixedly connected with traveling wheel 6. One side of the fixed plate 33 is rotationally connected with the side wall of the support plate 11 through a pin, and the other side of the fixed plate 33 is fixedly connected with a fixed rod, and the motor 9 is fixedly connected to the rod wall of the fixed rod, and the output end of the motor 9 Through the side wall of the fixed rod and fixedly connected w...

Embodiment 2

[0033] Embodiment 2: the difference based on Embodiment 1 is;

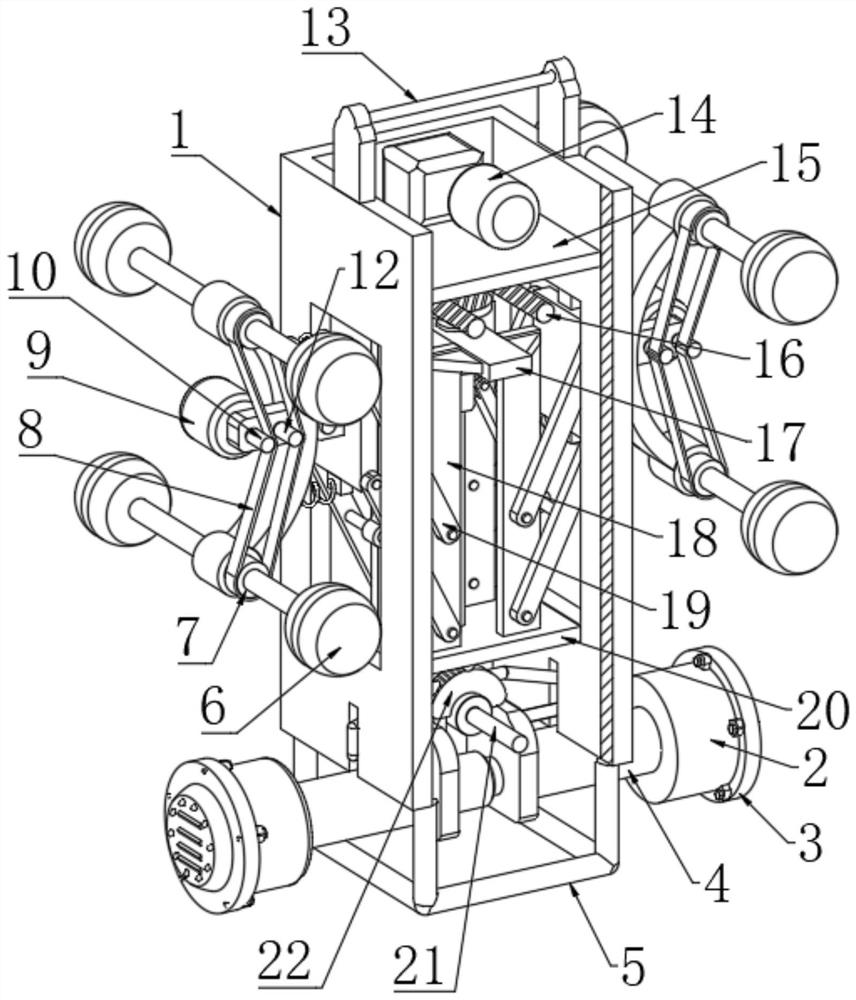

[0034] Refer to attached Figure 2-4 , the transmission mechanism includes a screw rod 38, the two ends of the screw rod 38 are respectively connected in rotation with the opposite side of the horizontal plate 15 and the mounting plate 20 through the second ball bearing, and the rod wall of the screw rod 38 is connected in rotation through the third rolling bearing. Positioning plate 17, the two ends of positioning plate 17 are all fixedly connected with the inner side of housing 1, and the relative both sides of positioning plate 17 are all symmetrically fixedly connected with two support rods 18, and the lower ends of two support rods 18 are all connected with mounting plate 20 The upper end of the support plate 11 is fixedly connected, and the two opposite sides of the support plate 11 are rotatably connected with two swing arms 19 through pins, and the ends of the two swing arms 19 away from the support plate ...

Embodiment 3

[0036] Embodiment 3: the difference based on embodiment 1 is;

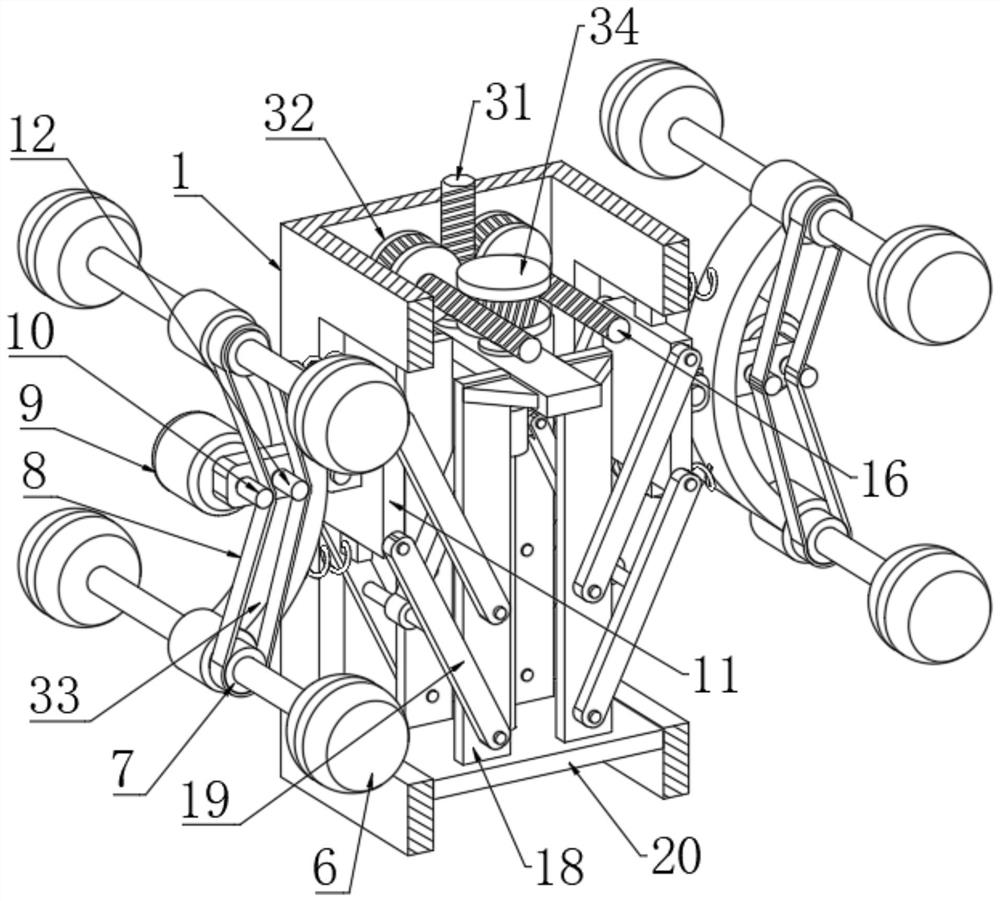

[0037] Refer to attached Figure 5-7 The shear mechanism includes two backing plates 30, a hydraulic cylinder 29 is fixedly connected between the two backing plates 30, a half gear 22 is fixedly connected to the shaft wall of the rotating shaft, and a reversing motor is fixedly connected to the side wall of the mounting plate 20 26. The output end of the reversing motor 26 is fixedly connected with the gear 27, the gear 27 meshes with the half gear 22, the end of the backing plate 30 away from the hydraulic cylinder 29 is fixedly connected with the first threaded column, and the backing plate 30 is threaded through the first threaded post There is a transmission connecting rod 4, and the length of the driving connecting rod 4 can be replaced with spare parts of different lengths according to actual usage requirements. There is a shearing head 2, and the side wall of the backing plate 30 is slidably sleeved with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com