A method and apparatus for real-time detection of infrared image abnormality of electric equipment in substation

A power equipment, real-time detection technology, applied in the detection field, can solve problems such as single task, difficult to extract image features of heating areas, large temperature changes, etc., achieve high detection accuracy and speed, real-time automatic detection of abnormalities and faulty equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

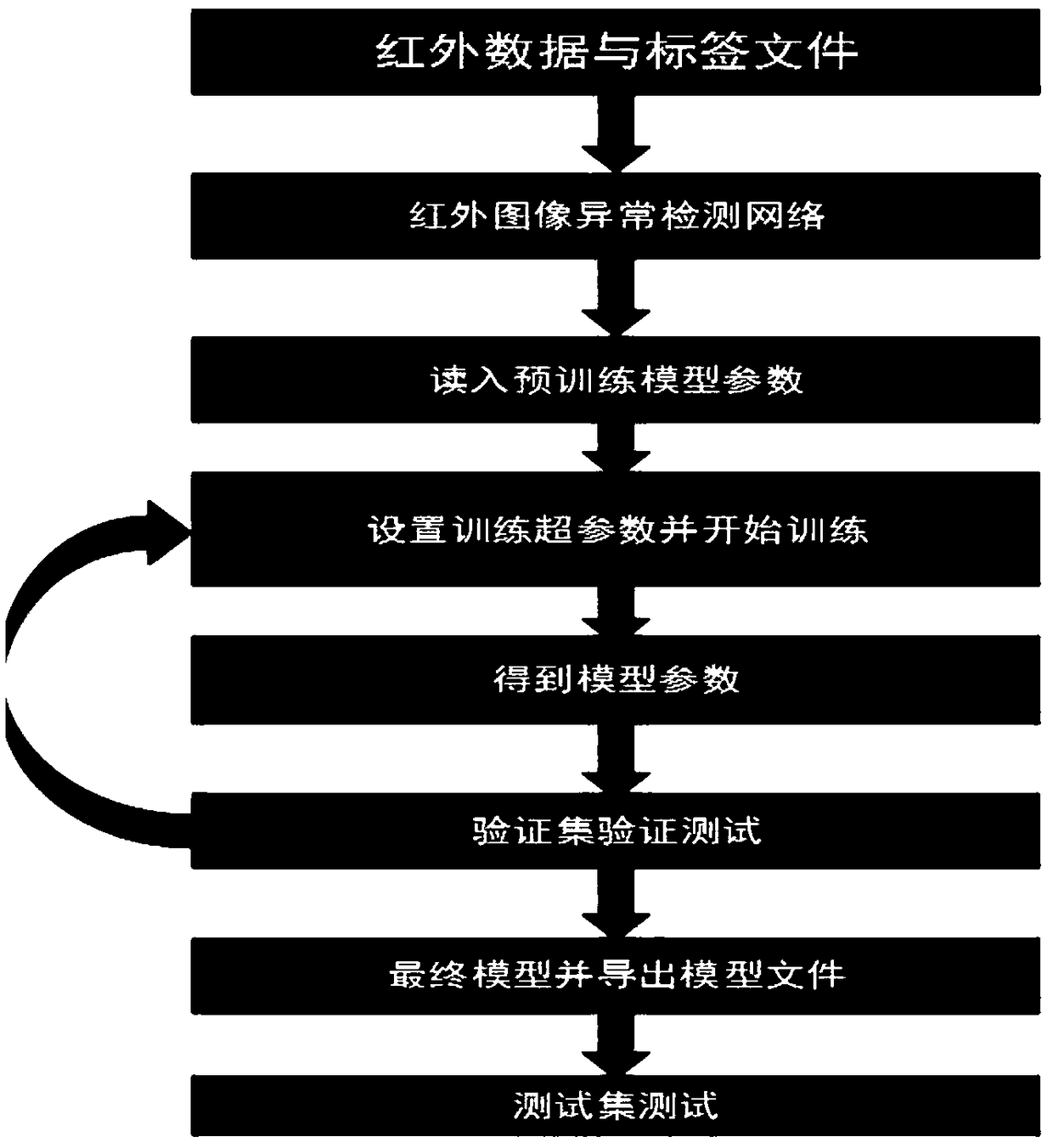

[0043] refer to figure 1 As mentioned above, the real-time detection method for infrared image abnormality of substation power equipment provided by this embodiment specifically includes:

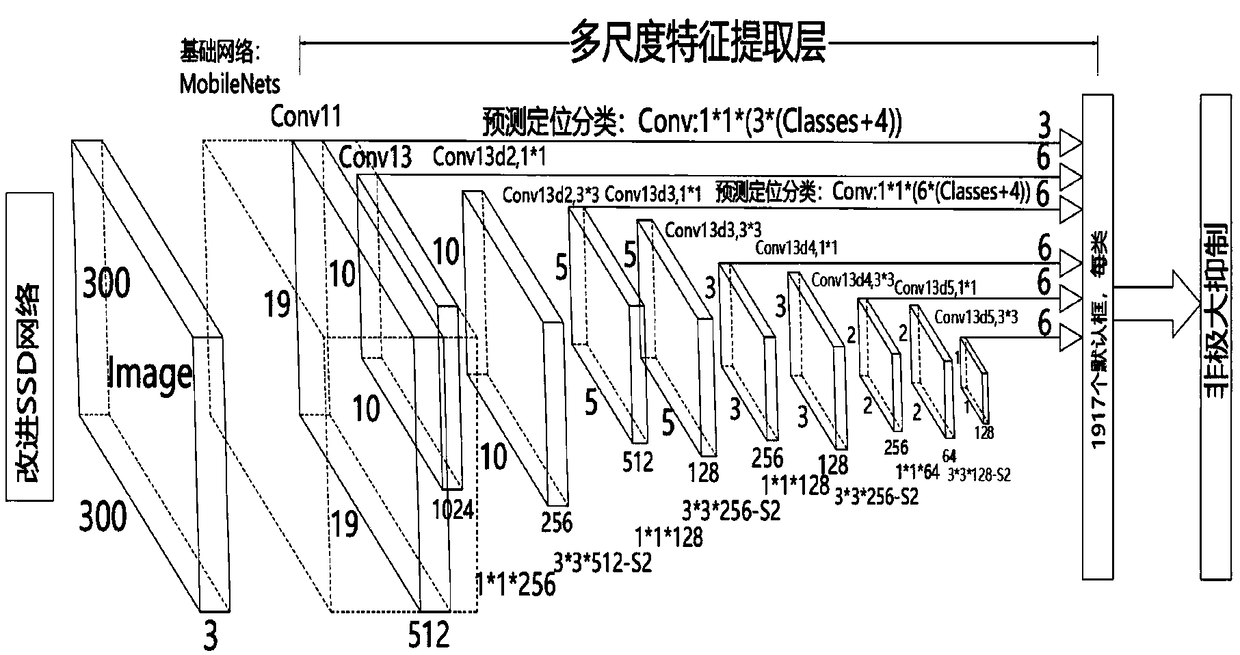

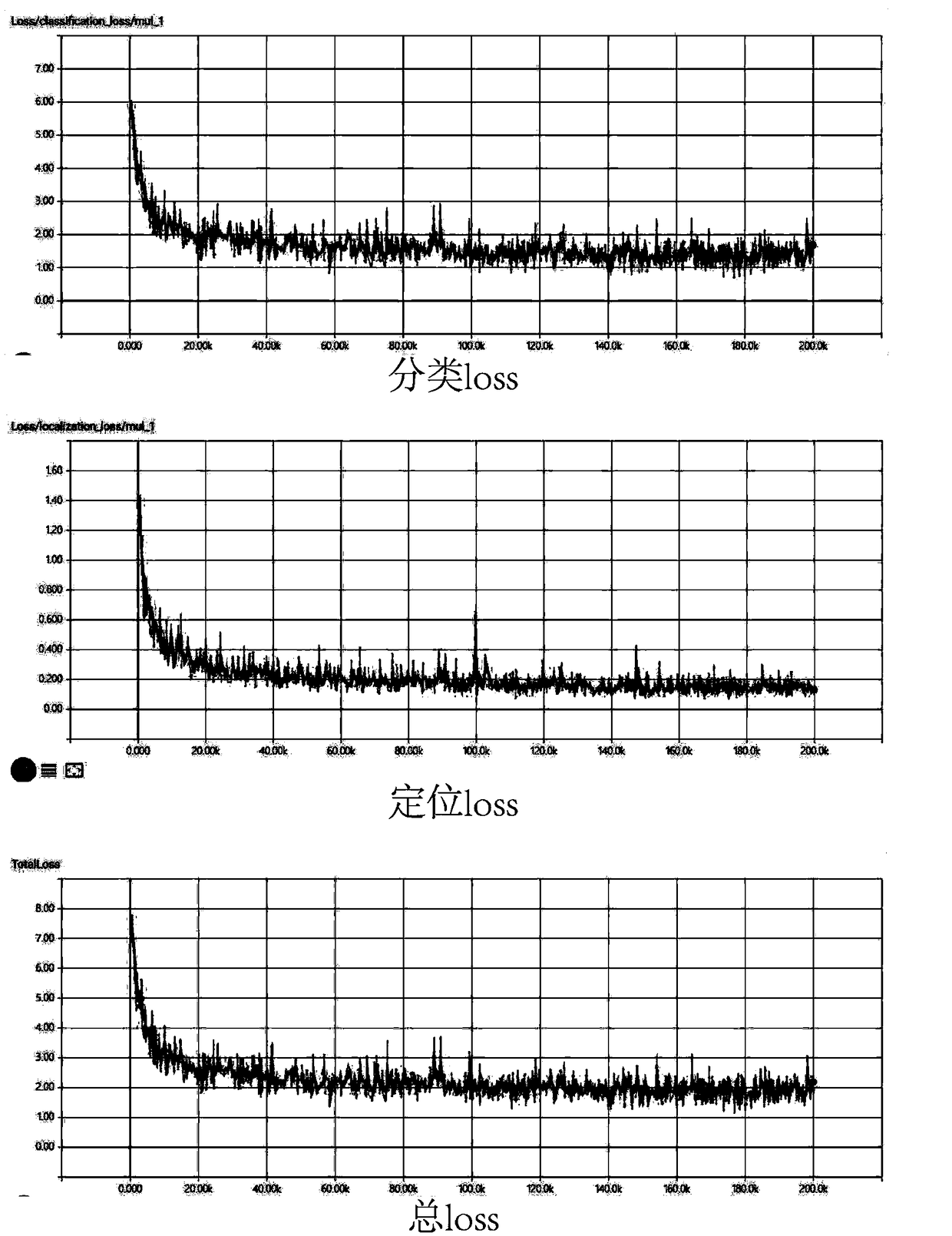

[0044]S1. Collect 1,000 images of abnormal infrared heating of electric equipment, remove abnormal samples, and obtain 863 images I of abnormal infrared heating of electric equipment, which are divided into 20 categories in order to solve the detection tasks of locating abnormalities and classifying faulty equipment. For the location of abnormal fever, in order to solve the detection problem of different shapes and sizes of abnormal areas in infrared images of power equipment, according to the area and shape of red hot areas in infrared images, it is considered to be divided into 7 categories, of which the seventh category is observation Class, and finally will judg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com