Underground coal mine drilling water draining and gas spraying prevention device and installation method thereof

A blowout prevention device and discharge technology, which is applied in the direction of gas discharge, safety device, drainage, etc., can solve the problems of insufficient buffer space, inability to separate water and gas, uncommon problems, etc., and achieve convenient operation and wide practicability , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

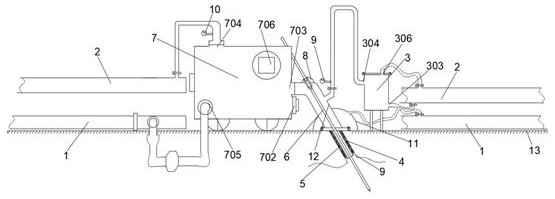

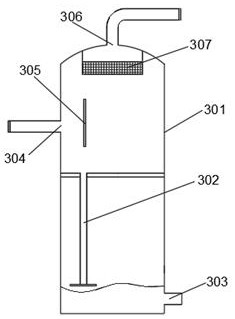

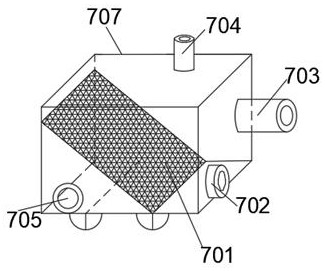

[0024] Such as figure 1 Shown; a coal mine drainage borehole water and gas blowout prevention device, including the orifice support sealing structure and the working order of the parallel first separation assembly and the second separation assembly. The orifice support structure comprises a hole protection pipe 5, a sealing sleeve 4, a hemispherical gas collection cover 11, and an air duct 12; the hole protection pipe 5 is composed of a pipe body and a flange, and the body of the hole protection p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com