A combined annular blowout preventer for oil drilling

An annular blowout preventer and oil drilling technology, which is applied in earth-moving drilling, wellbore/well components, sealing/packing, etc. Effectiveness of service life, avoiding adverse effects, and improving the reliability of blowout prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

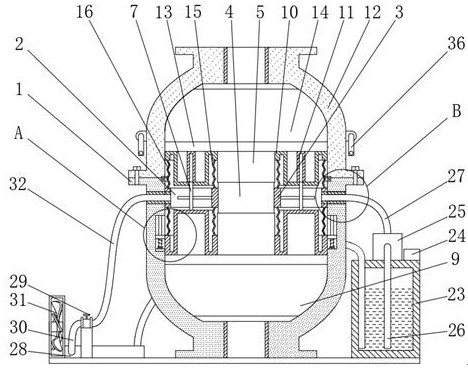

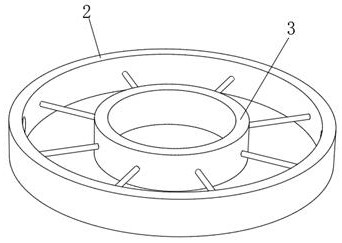

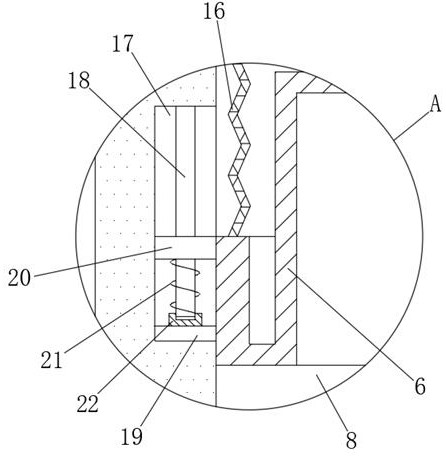

[0026] like Figure 1-6As shown, the embodiment of the present invention provides a combined annular blowout preventer for oil drilling, including a lower casing 1, an outer connecting ring 2 is fixedly connected to the inner side of the top of the lower casing 1, and an outer connecting ring 2 is fixedly connected to the inner side of the outer connecting ring 2 through a connecting rod. Inner connecting ring 3, the inner side of inner connecting ring 3 is fixedly connected with limiting tube 4, the outer sides of the upper and lower parts of limiting tube 4 are fixedly connected with anti-slip sleeve 5, and the outer side of anti-slip sleeve 5 at the lower part of limiting tube 4 is slidably connected with lower piston 6 And the lower piston 6 is slidably connected to the inner side of the lower housing 1, the top of the lower piston 6 is evenly provided with four limit posts 7, the bottom end of the lower piston 6 is fixedly connected with the lower push plate 8, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com