Rotary traveling wave ultrasonic motor with backup function and driving control method thereof

An ultrasonic motor, rotary type technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem that the ultrasonic motor cannot be coaxially backed up, and achieve torque Large, high maximum output speed, excellent low temperature start-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0058] Because of its self-locking characteristics, in the aerospace, nuclear power and other fields, when the ultrasonic motor fails, the motor cannot be replaced immediately, which will cause major losses. Therefore, an ultrasonic motor that can realize the backup function is needed. , there is no ultrasonic motor with a backup function at present.

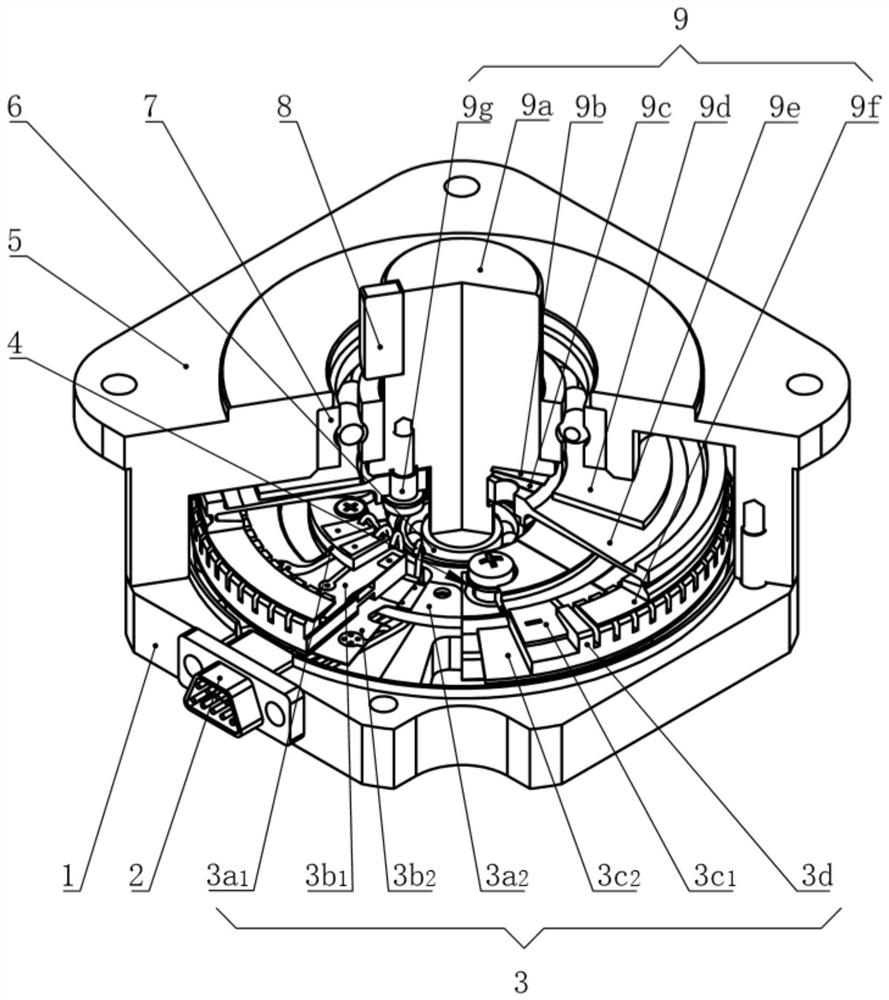

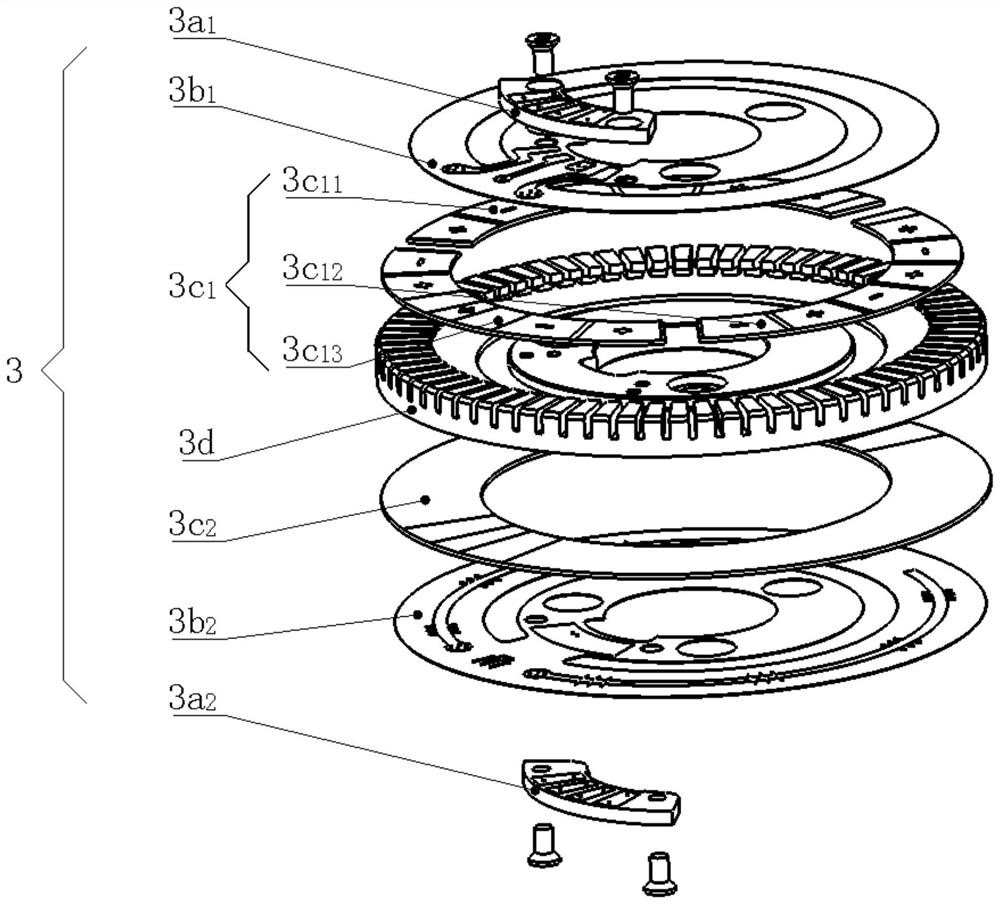

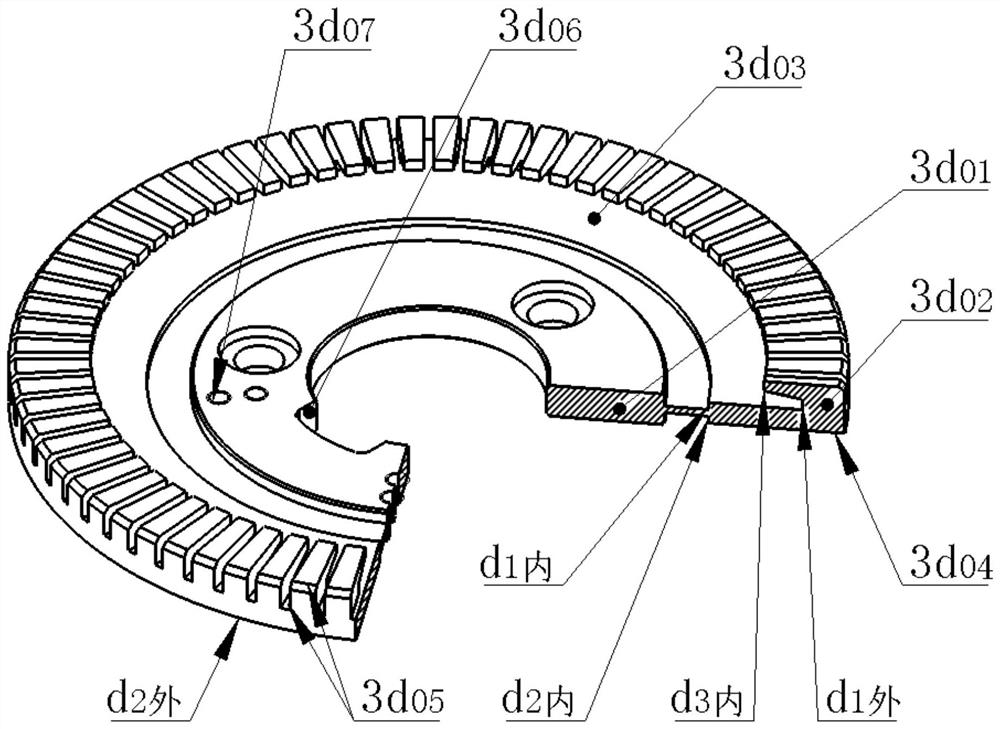

[0059] In order to solve the above problems, the application provides a rotary traveling wave ultrasonic motor with a backup function, including a stator base 1, a casing 5, a stator elastic body assembly 3 and a rotor assembly 9, and the stator elastic body assembly 3 is fixedly installed on the stator base 1 Ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com