Construct with chambers for thermal insulation

A technology of chambers and thermal insulation materials, applied in the field of quilted garment structure, can solve the problems of reducing the efficiency of garment thermal insulation and reducing the aesthetics of garments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

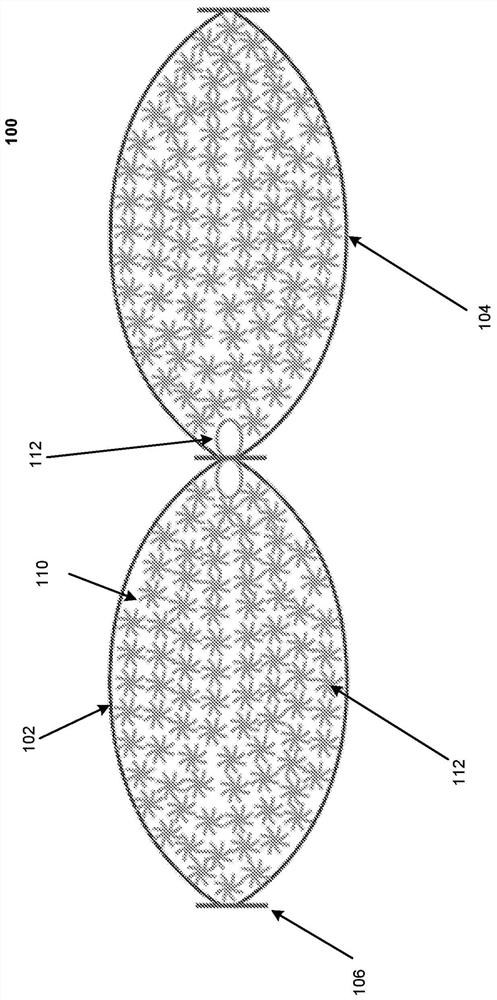

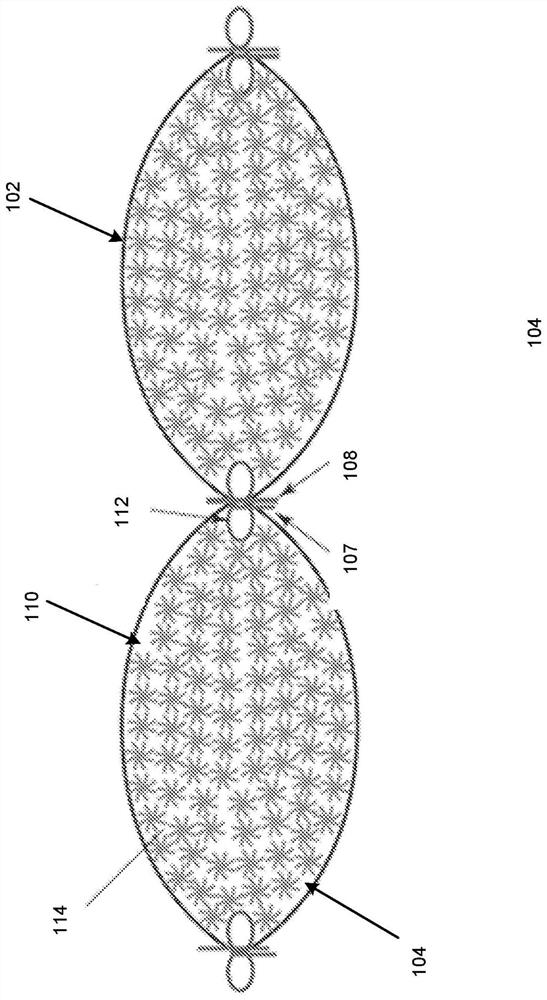

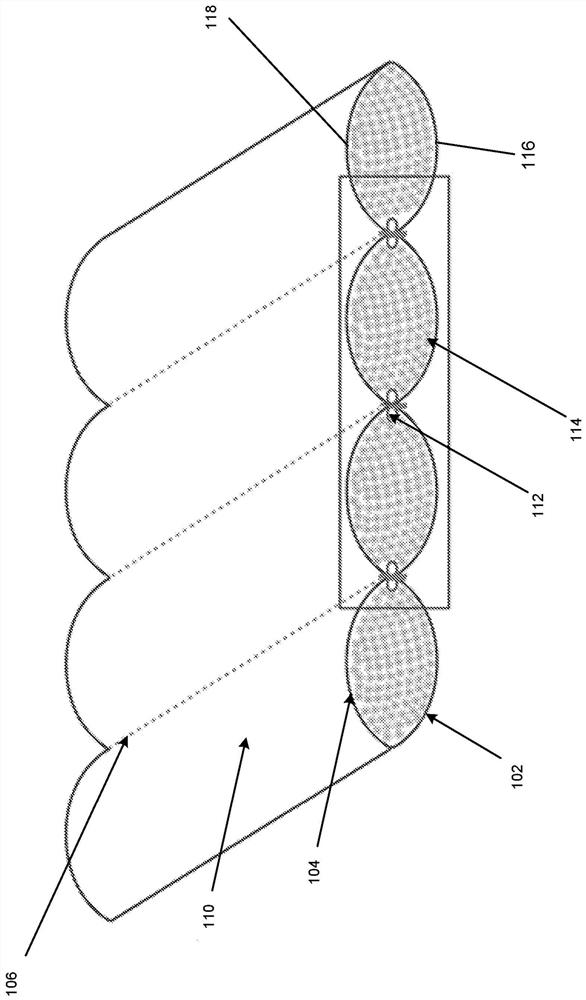

[0051] Example 1: A structure comprising: a first layer; a second layer disposed adjacent to said first layer such that said second layer is generally parallel to said first layer; a tubular insert disposed on said first layer between the first layer and the second layer; and a plurality of stitches configured to join at least a portion of the first layer to at least a portion of the second layer, wherein the plurality of stitches At least a portion of them passes through the tubular insert such that the tubular insert forms a curved cross-section, and wherein the plurality of sutures, the first and second layers, and the curved cross-section are formed in the A plurality of chambers are defined between the first layer and the second layer; and an insulating material is disposed within the plurality of chambers.

example 2

[0052] Example 2: The structure of Example 1, wherein the first layer or the second layer or both comprise fabric.

example 3

[0053] Example 3: The structure of Example 1, wherein the first layer or the second layer or both comprise a woven material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com