Inner container assembly of dish washing machine

A technology for a dishwasher liner and components, which is applied to parts of dishwashers/rinsing machines for tableware, washing machines/rinsing machines for tableware, household cleaning devices, etc., can solve the problems of high production cost, complex frame structure and poor aesthetics. and other problems to prevent spillover and improve the overall aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

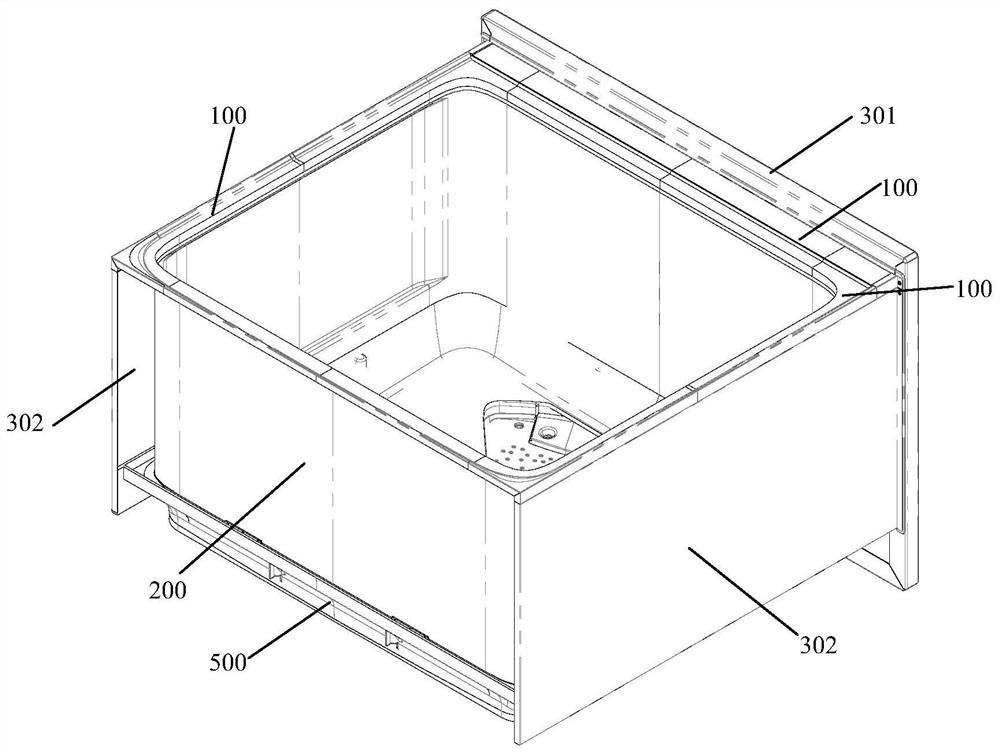

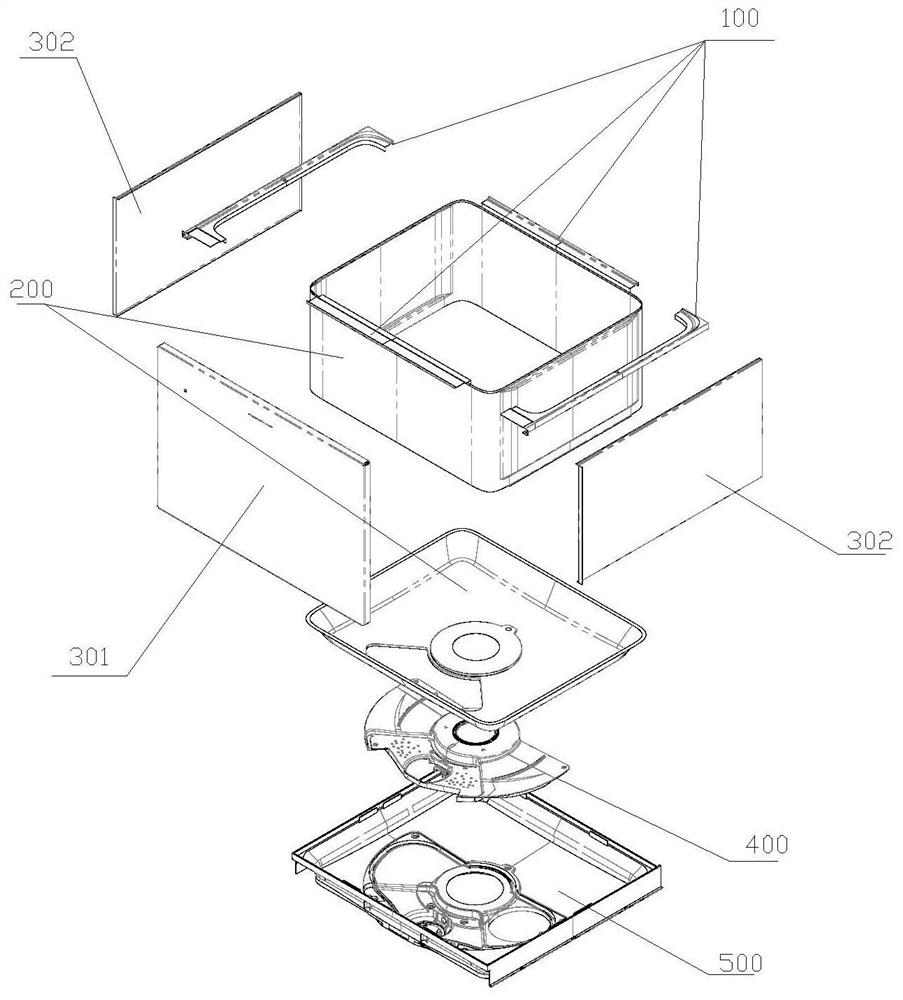

[0074] In this example, if figure 1 As shown, it includes the main body of the inner tank 200 and the door body 301 arranged on the side of the main body of the inner tank. The main body of the inner tank is provided with a connecting structure 100, and the door body 301 is provided with an assembly structure. The tank main body 200 is integrally connected with the door body 301. The setting of the assembly structure prevents the sharp edge of the wall surface of the connection structure from scratching the door body. At the same time, the connection structure is limited to make the overall assembly effect more compact and firm, and the aesthetics and performance of the dishwasher are improved. Improved security.

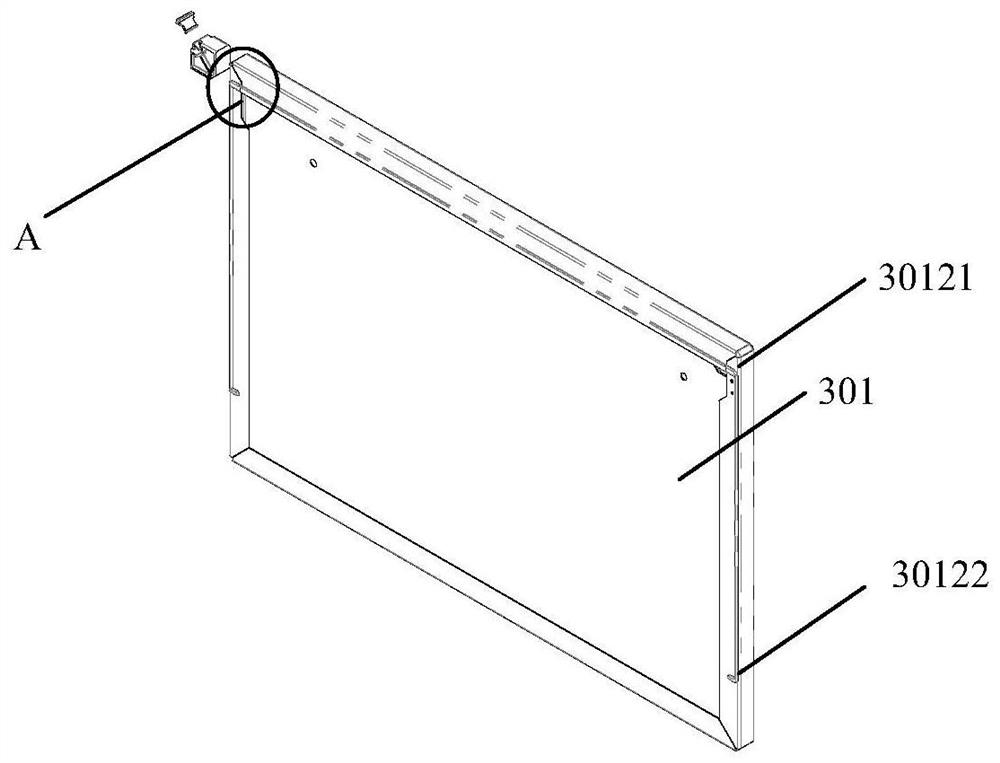

[0075] Such as image 3 As shown, the door body 301 includes an outer wall away from the inner container body 200, and the four sides of the outer wall surface are folded toward the inner container body 200 to form a plane, which serves as the thickness of the door...

Embodiment 2

[0085] This embodiment is a further limitation of the above-mentioned embodiment one, such as Figure 10 As shown, the liner main body 200 includes a side plate with a flat top, and the side plates are connected by a rounded transition side plate. The connection structure 100 includes a straight connection structure 1001 connected to the top of the side plate and a round The rounded connection structure 1002 for connecting the corner transition side panels.

[0086] The flat connection structure 1001 is in the shape of a strip, and the bottom surface of the straight connection structure 1001 is a flat surface consistent with the shape of the top surface of the connected side wall. The straight connection structure 1001 is integrally formed with the side plate of the main body 200 of the inner container, which greatly reduces the length of the welding seam during the processing of the dishwasher and improves the efficiency of product production.

[0087] The rounded connection...

Embodiment 3

[0101] Such as Figure 16 As shown, another connection form between the connection structure 100 and the inner container body 200 is introduced in this embodiment. The structure 100 is different. The connecting structure 100 in this embodiment includes a straight connecting structure 1001 connected to the front plate 201 and the rear plate 202 of the liner main body 200 respectively. Preferably, the straight connecting structure 1001 is connected to the front plate 201 / back plate 202 are integrally formed, and the straight connecting structure 1001 is the same as that in the second embodiment, and the door body connecting plate 10011 connected with the door body 301 is also provided; U-shaped connection structure 103, the overall shape of the U-shaped connection structure 103 is the same as that of the flat connection structure 1001 connected to the top surface of the side plate 203 and the rounded connection structure 1002 located on both sides of the flat connection structur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap