A modified glass fiber and its application, reinforced styrene-maleic anhydride copolymer composition and its preparation method

A technology of styrene maleic acid and glass fiber, which is applied to the reinforced styrene maleic anhydride copolymer composition and its preparation, modified glass fiber and application fields, and can solve the problem of poor processing releasability, poor appearance, physical Mechanical properties, such as low impact strength, can improve the surface floating fiber problem, improve the processing mold release, and improve the physical and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

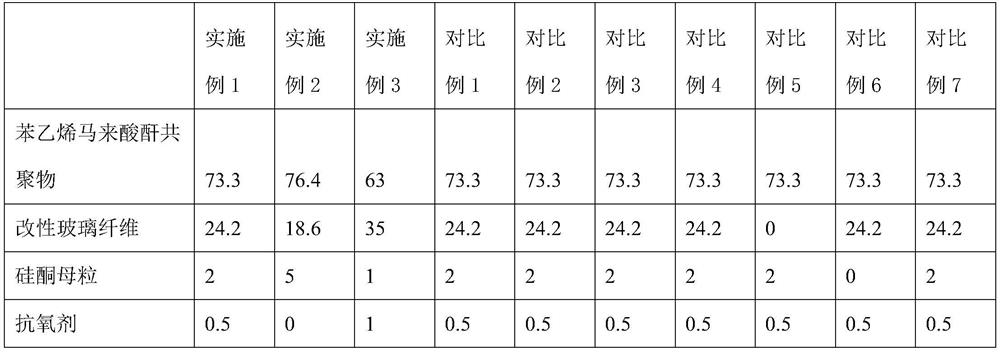

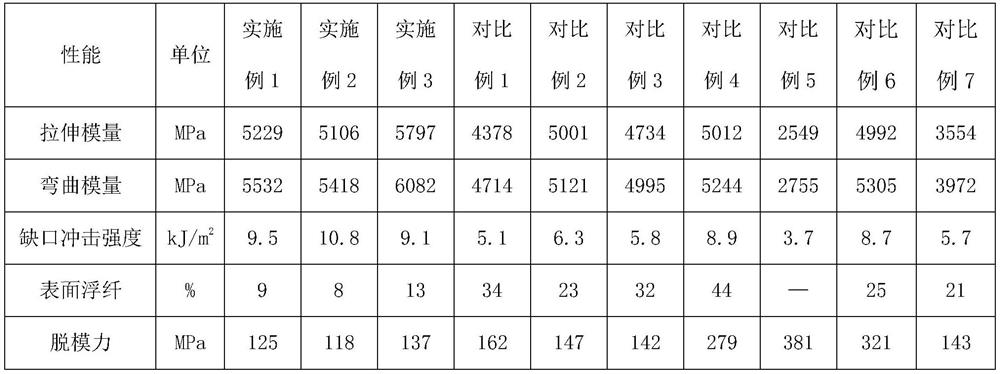

Embodiment 1 and comparative example 5-6

[0065] Raw material preparation:

[0066] Preparation of modified glass fibers:

[0067] Add 10 parts by weight of glass fiber A to 90 parts by weight of distilled water containing 3wt% emulsifier, stir and emulsify, keep the temperature at 70-80°C, and then evenly add 30 parts by weight of 10wt% lanthanum chloride aqueous solution and 20 The rare earth compound aqueous solution composed of 10 wt% cerium chloride aqueous solution, the dropping rate of the rare earth compound aqueous solution is 5 parts by weight / 10min, after the dropwise addition, stir at 70-80°C for 30min, and then pass into ammonia water Keep stirring, centrifuge after 2 hours, wash with distilled water for 3 times, and dry at 80°C for 8 hours after dehydration to obtain modified glass fiber.

[0068] Preparation of styrene maleic anhydride copolymer:

[0069] Take by weighing styrene and maleic anhydride, wherein the weight ratio of styrene and maleic anhydride is 75:25, dissolve maleic anhydride in styre...

Embodiment 2

[0078] Raw material preparation:

[0079] Preparation of modified glass fibers:

[0080] Add 10 parts by weight of glass fiber A to 80 parts by weight of distilled water containing 5wt% emulsifier, stir and emulsify, keep the temperature at 70-80°C, and then evenly add 30 parts by weight of 10wt% lanthanum chloride aqueous solution and 20 The rare earth compound aqueous solution composed of 10 wt% cerium chloride aqueous solution, the dropping rate of the rare earth compound aqueous solution is 5 parts by weight / 10min, after the dropwise addition, stir at 70-80°C for 30min, and then pass into ammonia water Keep stirring, centrifuge after 2 hours, wash with distilled water for 3 times, and dry at 80°C for 8 hours after dehydration to obtain modified glass fiber.

[0081] Preparation of styrene maleic anhydride copolymer:

[0082] Weigh styrene and maleic anhydride, wherein the weight ratio of styrene and maleic anhydride is 75:20, dissolve maleic anhydride in styrene, and add...

Embodiment 3

[0091] Raw material preparation:

[0092] Preparation of modified glass fiber:

[0093] Add 10 parts by weight of glass fiber A to 95 parts by weight of distilled water containing 2wt% emulsifier, stir and emulsify, keep the temperature at 70-80°C, and then evenly add 30 parts by weight of 10wt% lanthanum chloride aqueous solution and 20 The rare earth compound aqueous solution composed of 10 wt% cerium chloride aqueous solution, the dropping rate of the rare earth compound aqueous solution is 5 parts by weight / 10min, after the dropwise addition, stir at 70-80°C for 30min, and then pass into ammonia water Keep stirring, centrifuge after 2 hours, wash with distilled water for 3 times, and dry at 80°C for 8 hours after dehydration to obtain modified glass fiber.

[0094] Preparation of styrene maleic anhydride copolymer:

[0095] Weigh styrene and maleic anhydride, wherein the weight ratio of styrene and maleic anhydride is 75:30, dissolve maleic anhydride in styrene, and add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com