A kind of wear-resistant, damp-heat-resistant PC/abs material and preparation method thereof

An ABS material, heat and humidity resistance technology, applied in the field of polymer materials and their molding processing, can solve the problems of limiting the use range of materials, collision, touch, material embrittlement, etc., to improve the service life, improve the ability to resist external forces, reduce The effect of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

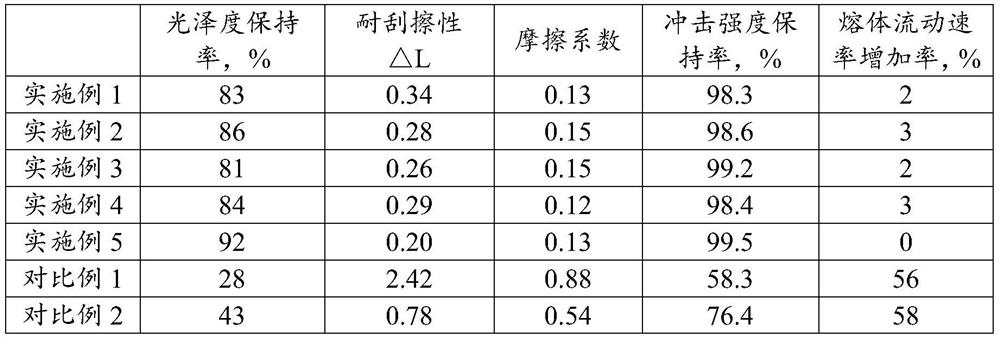

Examples

Embodiment 1

[0020] A kind of preparation method of abrasion-resistant, heat-and-humidity resistant PC / ABS material, concrete steps are as follows:

[0021] 56.7 parts of PC with a number average molecular weight of 20,000 g / mol, 30 parts of ABS with a number average molecular weight of 100,000 g / mol, composed of 20% butadiene, 20% acrylonitrile, and 60% styrene, and 5 parts of modified Hydrophobic graphene oxide, 1.5 parts of acrylonitrile-styrene copolymer grafted maleic anhydride, 6 parts of methyl methacrylate-butadiene-styrene copolymer, 0.2 part of antioxidant 245 and 0.3 part of antioxidant 1076 , 0.3 parts of silicone powder are weighed according to the number of parts, mixed with a high mixer for 3 minutes, and then added to the main feed port at one end of the screw extruder with a length-to-diameter ratio of 40:1, and melted together. Mixing, extruding at 220°C for granulation, screw speed at 400rpm, to obtain PC / ABS materials with wear resistance and heat and humidity resistanc...

Embodiment 2

[0025] A kind of preparation method of abrasion-resistant, heat-and-humidity resistant PC / ABS material, concrete steps are as follows:

[0026] 68.7 parts of PC with a number average molecular weight of 30,000 g / mol, 20 parts of ABS with a number average molecular weight of 120,000 g / mol, composed of 20% butadiene, 25% acrylonitrile, and 55% styrene, and 4 parts of modified Hydrophobic graphene oxide, 2 parts of acrylonitrile-styrene copolymer grafted glycidyl methacrylate, 4 parts of methyl methacrylate-acrylic polymer, 0.8 part of antioxidant 168, 0.5 part of pentaerythritol ester by parts Weigh it, mix it with a high mixer for 4 minutes, then add it into the screw extruder through the main feeding port at one end of the screw extruder with a length-to-diameter ratio of 36:1, and carry out melt blending. The extrusion temperature is 200°C. Granules, screw speed 500rpm, wear-resistant, heat-resistant PC / ABS material.

[0027] The preparation method of above-mentioned modifie...

Embodiment 3

[0030] A kind of preparation method of abrasion-resistant, heat-and-humidity resistant PC / ABS material, concrete steps are as follows:

[0031] 42.5 parts of PC with a number average molecular weight of 25000g / mol, 40 parts of ABS with a number average molecular weight of 80000g / mol, composed of 25% butadiene, 15% acrylonitrile and 60% styrene, and 6 parts of modified Hydrophobic graphene oxide, 2.5 parts of polymethyl methacrylate grafted maleic anhydride, 8 parts of ethylene-methyl acrylate, 0.1 part of antioxidant 245, 0.2 part of antioxidant 1076, 0.7 part of ethylene bisstearamide The parts are weighed, mixed with a high-speed mixer for 3 minutes, and added to the main feed port at one end of the screw extruder with a length-to-diameter ratio of 40:1, and melted and blended. The extrusion temperature is 240 ℃ granulation, screw speed 300rpm, wear-resistant, heat-resistant PC / ABS material.

[0032] The preparation method of above-mentioned modified hydrophobic graphene ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com