Dredger for building downspout and clearing method

A technology of unblocker and downpipe, which is applied in water supply installations, indoor sanitary plumbing installations, buildings, etc. It can solve the problems of inconvenient dredging of downpipes, achieve the effect of reducing occupied space and improving cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

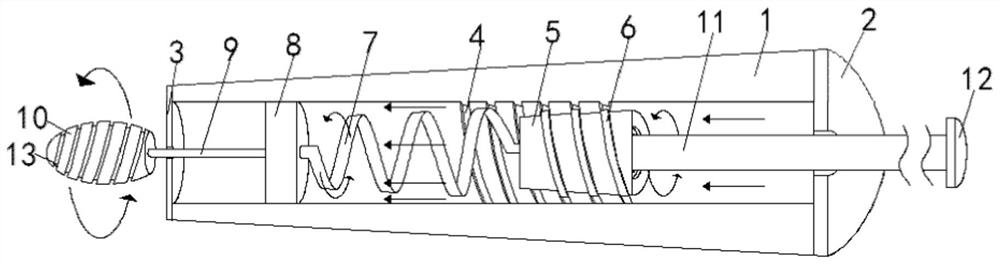

[0028] see Figure 1-2 , the present invention provides a technical solution: a dredger for building downpipes, comprising a conical sleeve 1, the top and bottom of the conical sleeve 1 are fixedly connected with a top cover 2 and a bottom cover 3, and the inner wall of the conical sleeve 1 is opened There is a spiral track 4, a plug block 5 is sleeved in the tapered sleeve 1, a spiral bar 6 is sleeved on the plug block 5, and the spiral bar 6 is sleeved in a part of the spiral track 4, the coil diameter of the spiral bar 6 and the distance between the spring wire The distance between them is equal to that of the helical track 4. For this reason, the helical bar 6 can normally mesh with the helical track 4, and only a part of the helical bar 6 is nested in the helical track 4. With the rotation of the helical bar 6, it can gradually Through the spiral track 4, the bottom of the plug block 5 is flexibly connected to the top of the receiving block 8 through the coil spring 7, th...

Embodiment 2

[0031] see Figure 1-2 , on the basis of Embodiment 1, the present invention provides a technical solution: the bottom end of the push rod 11 is fixedly connected with the top of the block 5, at this time, if you want to move the block 5 downward, you must rotate the push Rod 11, so that the coil spring 7 can be gradually compressed in a rotating manner, and at the same time, the receiving block 8 will gradually drive the dredging head 10 to descend and rotate through the transmission rod 9 in a rotating manner, when the receiving block 8 touches the bottom When the top of the cover 3, the coil spring 7 will be gradually compressed. At this time, the rotation of the dredging head 10 can be made smoother and more convenient. The corners on the platform provide enough room for the arms of the staff to use this embodiment .

Embodiment 3

[0033] see Figure 1-2 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the bottom end of the push rod 11 is movably connected with the top of the block 5 through a bearing, and the surface of the dredging head 10 is provided with a spiral groove 13 , at this time, just press the push block 12, the push rod 11 can be pushed down to press the plug block 5, and under the action of the spiral bar 6 and the spiral track 4, the plug block 5 can push the receiving block 8 downward through the coil spring 7 Move, at this time, the transmission rod 9 will drive the dredging head 10 to descend by rotation. When the corner space on the platform is relatively cramped and it is inconvenient for the staff to move their arms, they can directly press down. On the one hand, it is safer, and on the other hand, it can be used It is more convenient to look up, and the spiral groove 13 on the dredging head 10 can deform the garbage, and can cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com