A kind of tight wire take-up device for steel strand

A technology of wire take-up and steel strand, which is applied in the field of steel strand winding, which can solve the problems of loose stranding of steel wire, weak toughness of steel wire, and influence on actual use, so as to ensure stability and neatness, fast storage, and avoid excessive The effect of tension or over-relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

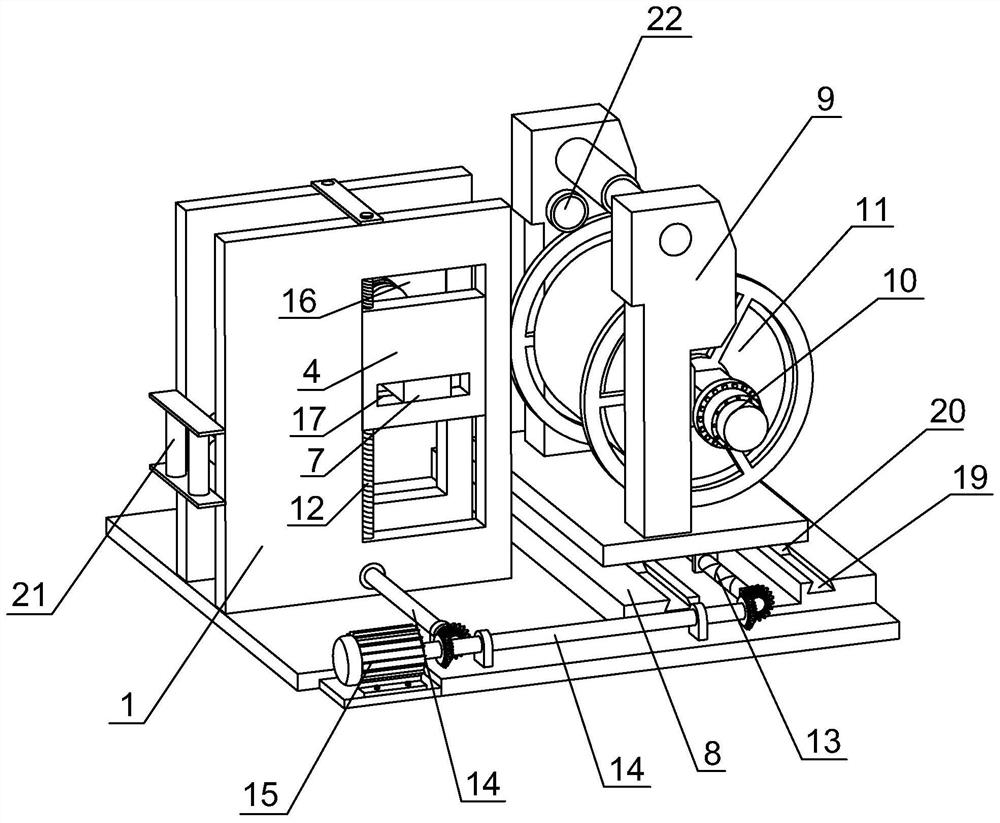

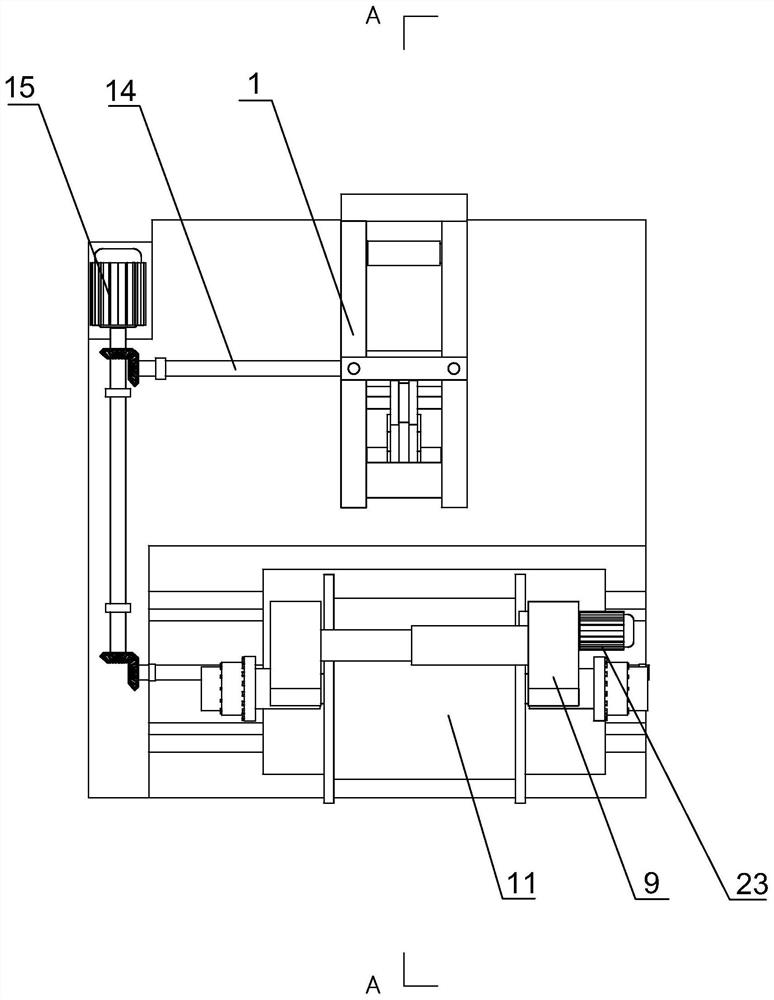

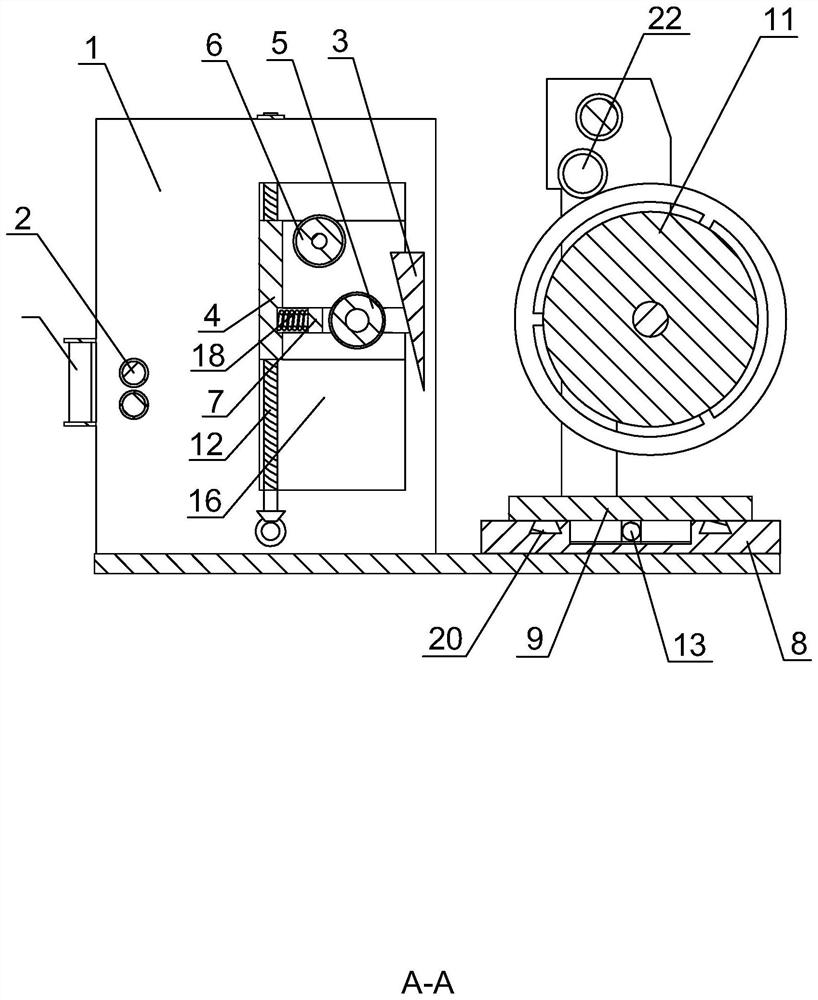

[0032] refer to figure 1 , is a wire tightening take-up device for a steel strand disclosed in the present invention, comprising a tightening unit and a take-up unit arranged successively, the tightening unit is used for tensioning the steel strand, and the take-up unit is used for winding the steel strand line, and also includes a drive unit for synchronously driving the above two operations.

[0033] The line tightening unit includes a base 1. The base 1 is composed of two parallel and vertically arranged vertical plates. There is a slideway 16 inside the base 1. Double splints 4 are provided for lifting and sliding in the slideway 16. The double splints 4 The cross section is in the shape of "C". The double splint 4 is straight up and down on the slideway 16 inside the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com