Melt-blown cloth winding device

A technology of winding device and melt-blown cloth, which is applied in the direction of heating device, drying gas arrangement, winding strip, etc., which can solve the problems that the melt-blown cloth cannot be dried, the drying effect is poor, and the melt-blown cloth is not dried. , to achieve the effect of improving aesthetics, avoiding local heating and speeding up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

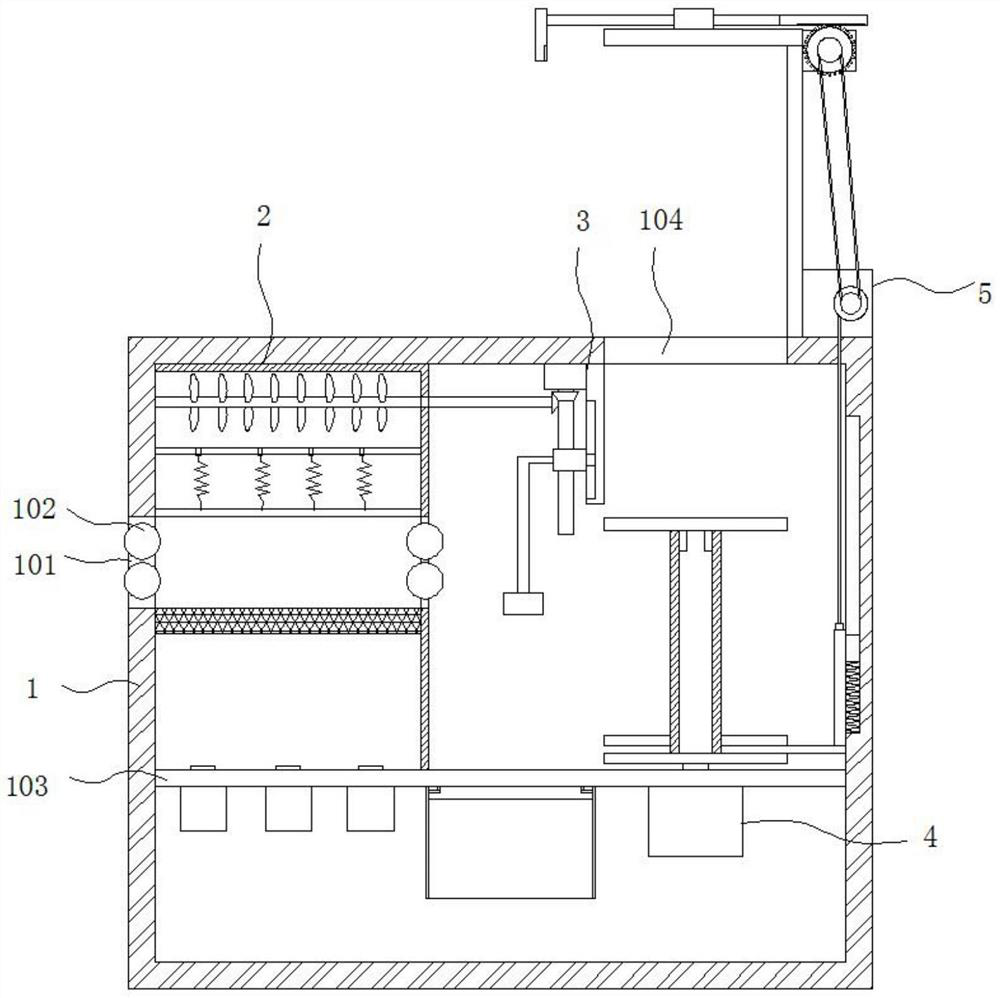

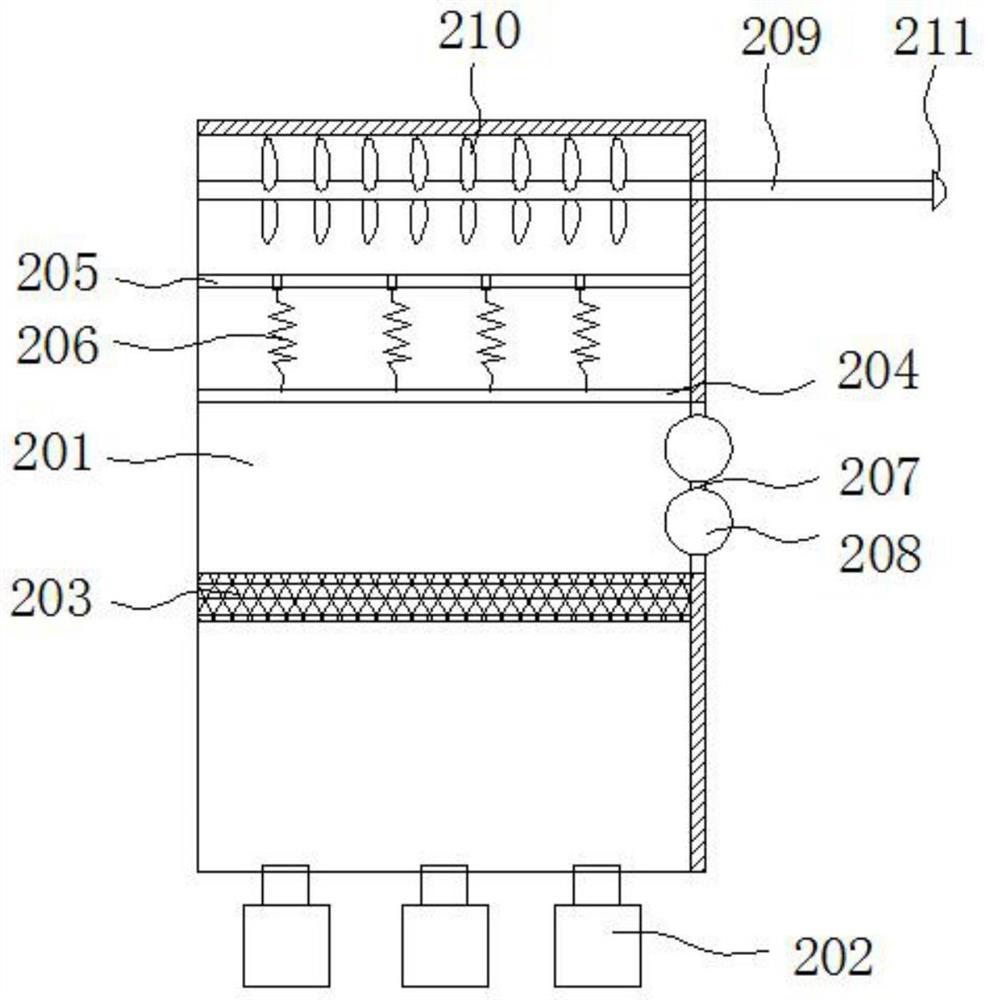

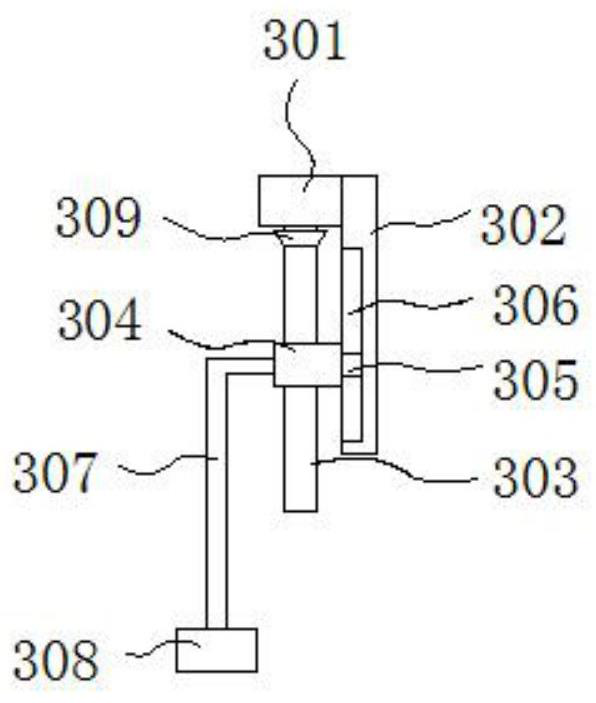

[0024] see Figure 1-5 , the present invention provides a technical solution:

[0025] A meltblown cloth rewinding device, comprising a processing cabinet 1, a drying mechanism 2, an adjusting mechanism 3, a winding mechanism 4 and a feeding mechanism 5, a cloth inlet 101 is provided on one side of the processing cabinet 1, and the cloth inlet 101 rotates inside Two nip rollers 102 are connected, and the two nip rollers 102 are distributed up and down. The inside of the processing cabinet 1 is horizontally fixedly connected with a partition 103. The top side of the processing cabinet 1 is provided with a feeding port 104. The drying mechanism 2 includes a drying bin 201 and A plurality of hot air blowers 202, the drying bin 201 is fixed on the top side of the partition 103, the hot air blower 202 is fixed on the bottom side of the partition 103, and the hot air blower 202 is connected with the bottom of the drying bin 201, and the feeding mechanism 5 includes a servo motor 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com