A leather carving hydraulic device and embossing method

A hydraulic device and leather carving technology, which is applied in leather drying, leather surface mechanical treatment, raw hide/leather/fur manufacturing equipment, etc. The flower effect is good, the quality is improved, and the effect of force is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

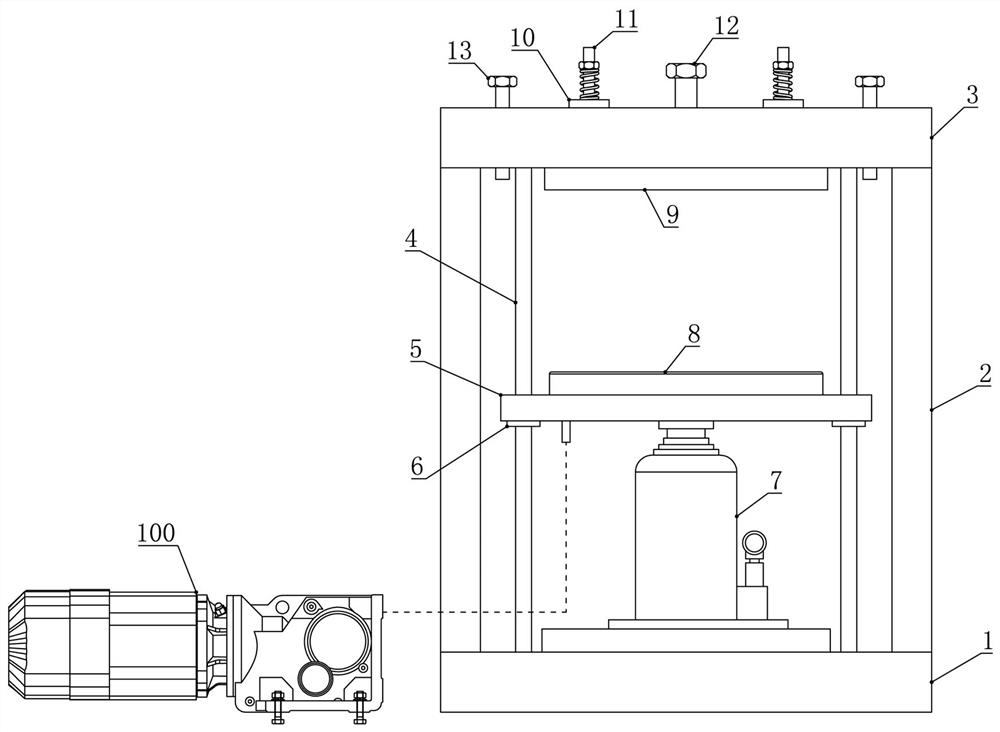

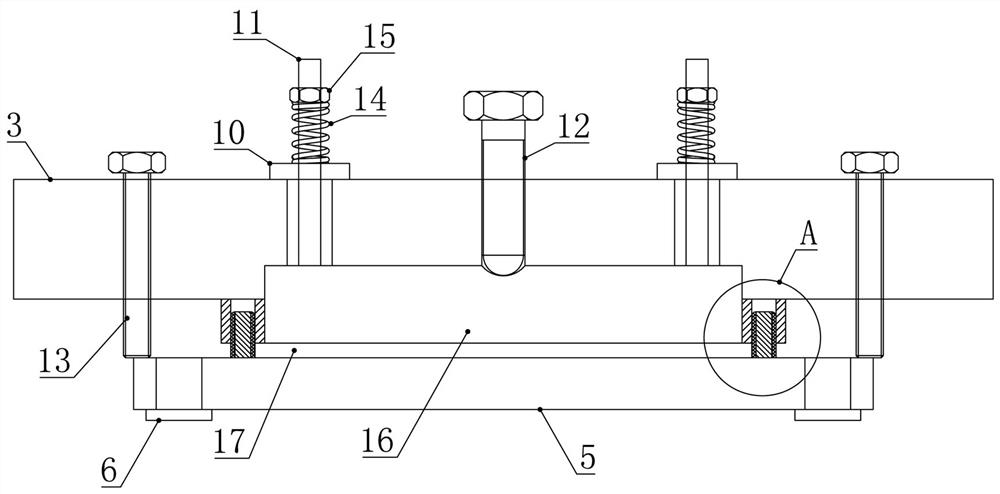

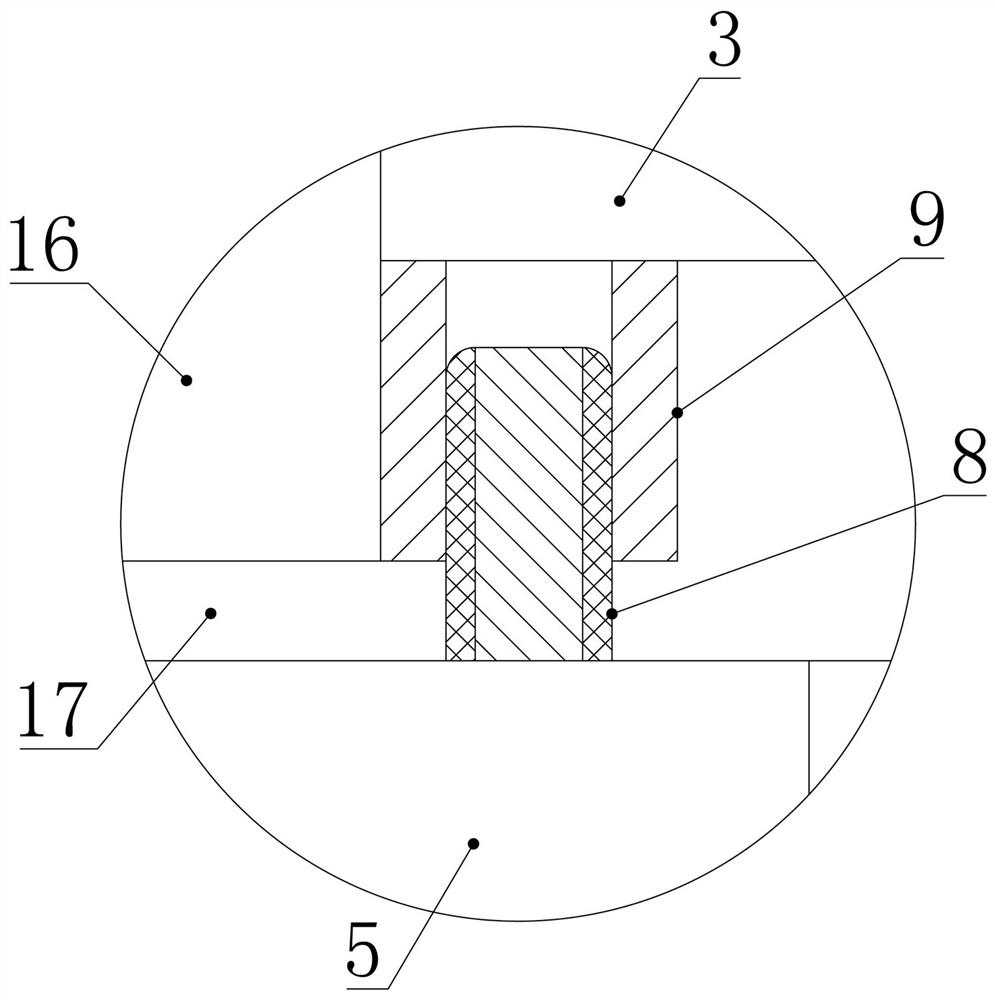

[0035] like figure 1 A kind of leather carving hydraulic device shown, it comprises frame, hydraulic jack 7, upper pressing plate 16 and lower pressing plate 5, and described frame comprises base 1, side support plate 2 and upper support plate 3, and described side support plate 2 fixedly arranged between the base 1 and the upper support plate 3, the base 1, the side support plate 2 and the upper support plate 3 are all made of metal materials with strong structural strength, such as stainless steel, the base 1, the side support plate 2 and the upper support plate The supporting boards 3 can bear relatively high pressure without deformation.

[0036] The hydraulic jack 7 is fixedly arranged on the base 1 in the frame, the top of the hydraulic jack 7 is connected to the bottom of the lower pressing plate 5, and the frame is provided with a plurality of A guide column 4, a sliding sleeve 6 is arranged on the lower platen 5, and the sliding sleeve 6 is compatible with the guide ...

Embodiment 2

[0051] A kind of leather carving embossing method based on the leather carving hydraulic device as described in embodiment 1, it comprises the steps:

[0052] Step 1: Preheat the leather carving hydraulic device; adjust the position of the limit screw 13; wet the leather block to be embossed; it can be wetted by spraying with a watering can;

[0053] Step 2: Place the wetted leather piece and the embossing mold on the lower platen 5, with the leather piece on top and the embossing mold on the bottom;

[0054] Step 3: Manually shake and press the hydraulic jack to push the lower pressing plate 5 to rise vertically until the lower pressing plate 5 touches the limit bolt 13 and cannot rise any further; 16 contact, apply a certain pressure through a torque wrench and keep it. At this time, the lower platen 5, the upper platen 16 and the sealing ring structure on it cooperate to form a closed cavity; applying pressure through a torque wrench can ensure the accuracy and controllabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com