Isolation structure for continuous beam grouting layer and grouting method

A technology of isolation structure and isolation layer, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., and can solve problems such as difficulty in realization, easy residue of formwork, easy penetration into beam holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

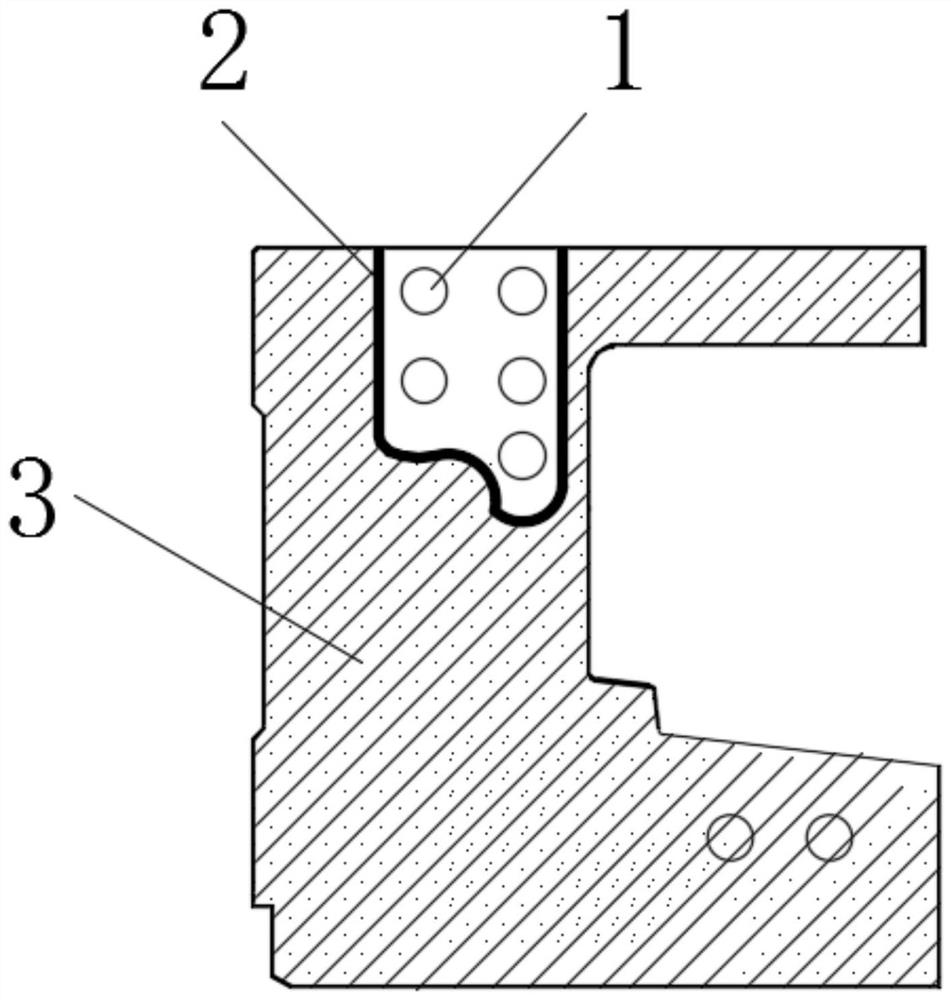

[0018] Such as figure 1 As shown, in this embodiment, an isolation structure for continuous beam grouting layer includes two adjacent simply supported beams 3 and a flexible isolation layer 2 arranged between the two simply supported beams 3. The flexible isolation layer 3 surrounds the outer side of the prestressed beam hole 1.

[0019] Surround the flexible isolation layer 3 on the outside of the prestressed piercing hole 1, so that the flexible isolation layer 3 is in sealed contact with the simply supported beams 2 on both sides, so as to form an isolation area isolated from the grouting area, and grouting is performed in the grouting area No, it can prevent concrete from entering the isolation area. The flexible deformation of the flexible isolation layer 3 can fill up the gap between the flexible isolation layer 3 and the simply supported beam 2, enhance the sealing strength of the flexible isolation layer 3 and the simply supported beam 2, and prevent concrete from leakin...

Embodiment 2

[0022] On the basis of the foregoing embodiment, in this embodiment, a supporting structure for supporting the flexible isolation layer 2 is provided between the two simply supported beams 3. The use of a supporting structure to support the flexible isolation layer 2 is beneficial to keep the position of the flexible isolation layer 2 stable and avoid displacement of the flexible isolation layer 2 under the impact of concrete.

[0023] In this embodiment, the supporting structure uses steel bars. A number of short steel bars are prefabricated or embedded around the prestressed beam hole 1, and the short steel bars are used to support and limit the flexible isolation layer 2.

[0024] The short steel bars can be arranged on the inner and outer sides of the flexible isolation layer 2. When concrete is poured or the isolation area is filled later, the short steel bars do not need to be removed and no additional impurities are introduced.

Embodiment 3

[0026] On the basis of the foregoing embodiment, in this embodiment, the flexible isolation layer 2 adopts a flexible hose. In this way, the volume of the flexible hose can be controlled by water injection or air injection, so that the flexible isolation layer 2 can be placed between two adjacent simply supported beams 3. After the flexible hose contacts the simply supported beam 3, the elastic Water or air is continuously injected within the deformation limit to make the flexible hose and the simply supported beam 3 fully contact to eliminate the gap, thereby increasing the sealing strength between the flexible hose and the simply supported beam 3.

[0027] In this embodiment, one end of the flexible hose is closed, and the other end is provided with an opening. By providing an opening helps to reduce the risk of leakage.

[0028] The opening of the flexible hose is provided with a locking structure. In this way, during construction, the opening is locked by the locking structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com