A control method for urea tank thawing and heating state

A control method and technology of urea tank, which is applied to the electronic control of exhaust treatment devices, machines/engines, mechanical equipment, etc., can solve problems such as unqualified exhaust gas and failure to meet regulatory requirements, and achieve the effect of improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

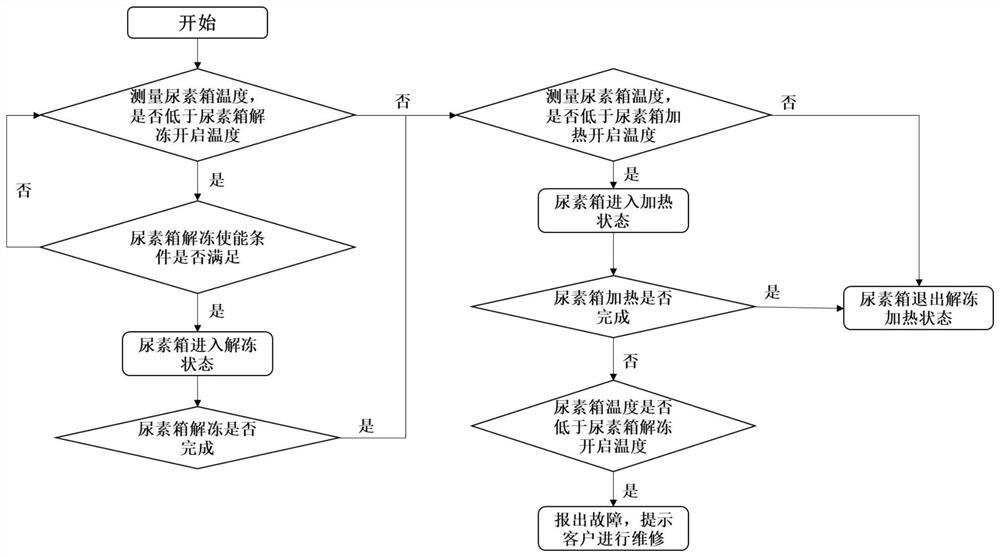

[0024] In this embodiment, the urea tank is thawed and heated with cooling water, and is thawed and heated by controlling whether the cooling water of the diesel engine circulates through the water cut-off solenoid valve; a method for controlling the thawing and heating state of the SCR urea tank is based on the urea tank The temperature is calculated as the input of the urea tank thawing and heating state, and the output is the duty ratio of the water cut-off solenoid valve of the urea tank, which should be composed of the diesel engine electronic control unit, the urea tank, the temperature sensor of the urea tank, the urea quality sensor, and the water cut-off solenoid valve In the selective catalytic reduction SCR system, the urea tank temperature sensor and urea quality sensor are integrated inside the urea tank, the water cut-off solenoid valve is installed outside the urea tank, and the urea quality sensor also has a temperature module inside to correct the urea concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com