A drop tester capable of simulating continuous drops

A testing machine and prototype technology, applied in the field of testing, can solve problems such as difficulty in adapting to the testing requirements of the product to be tested, single drop testing results, single drop testing height, etc., achieving rich and diverse testing indicators, avoiding human factor interference, and avoiding loosening. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

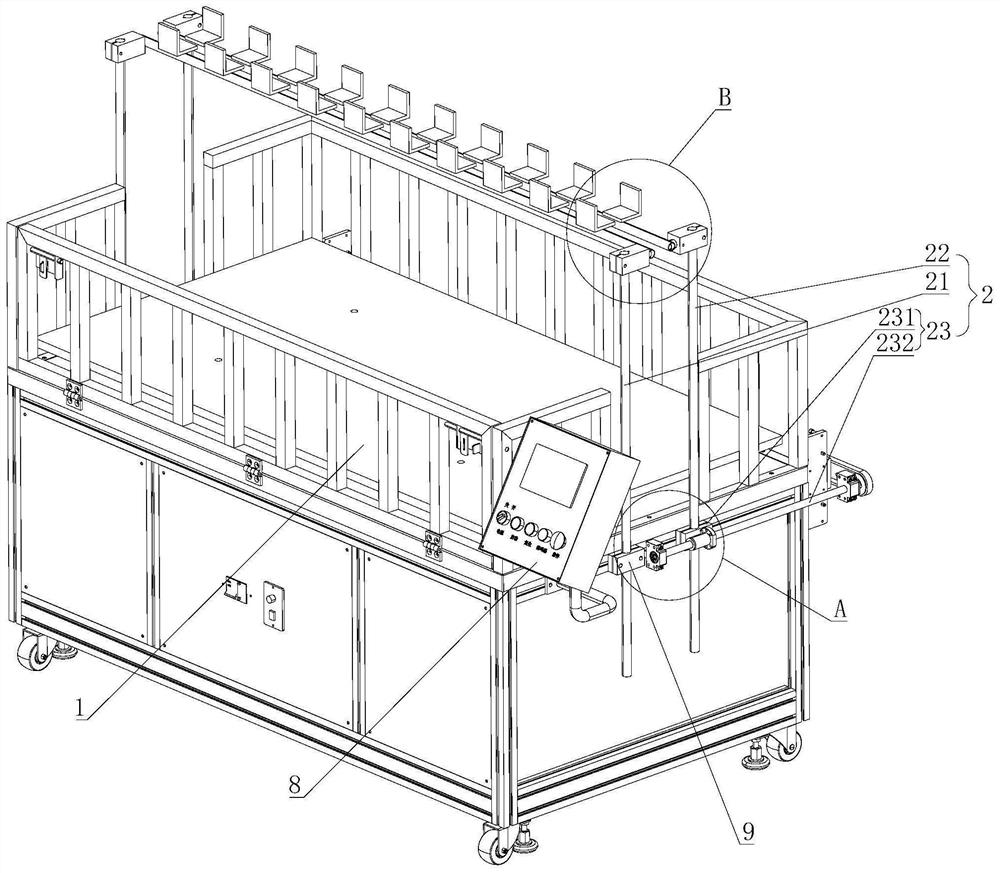

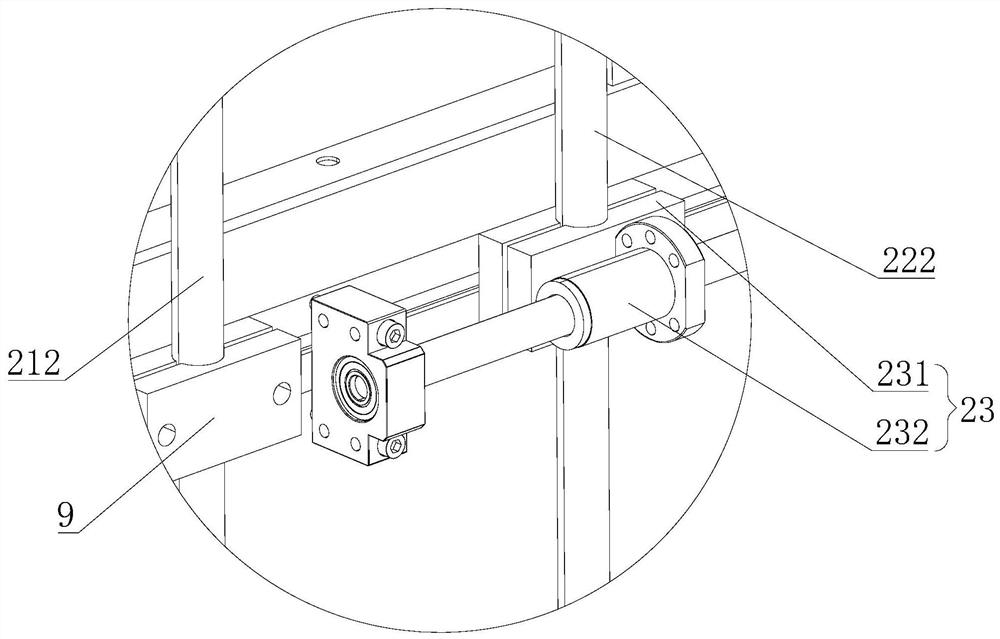

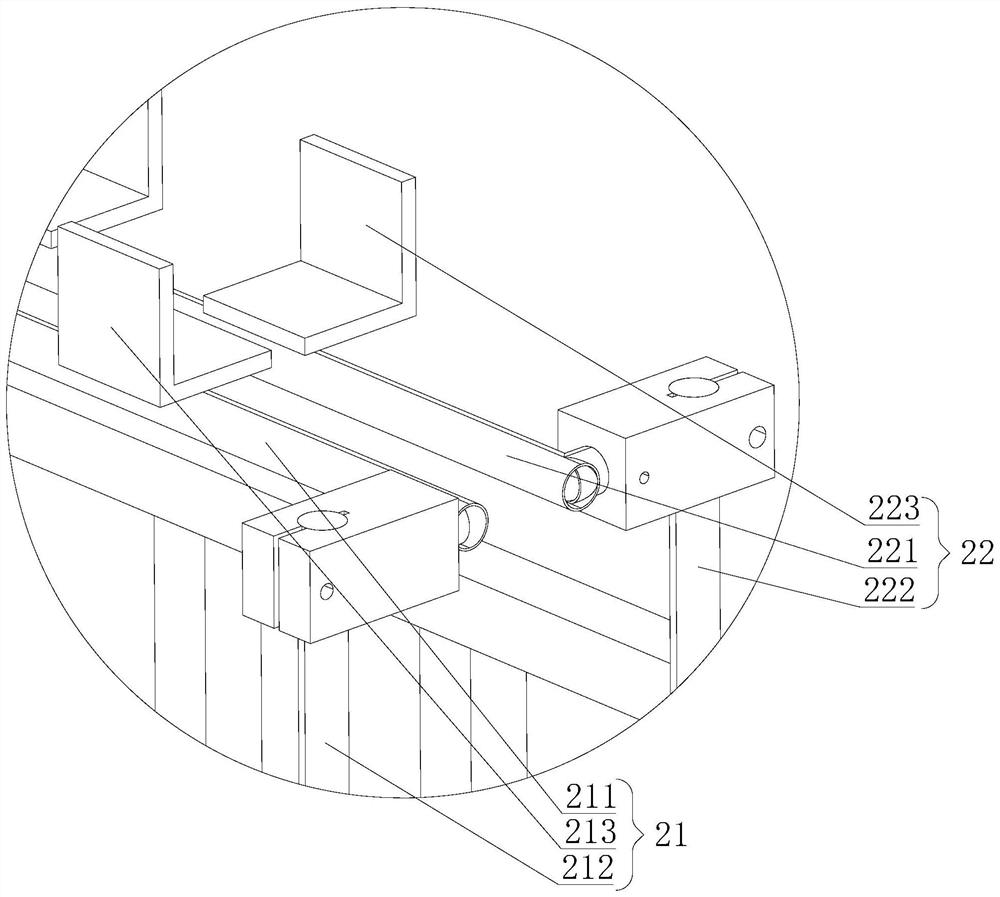

[0025] Such as Figure 1 to Figure 4 As shown, the drop test machine provided in this embodiment can simulate continuous drop. In order to make the drop test machine simulate the continuous drop state without manually clamping and adjusting different test heights multiple times, it is more convenient and quick, and the test index More rich and varied. Further, the drop test machine capable of simulating continuous drop includes a stage 1 for receiving the sample machine to be tested and a clamping mechanism 2 for clamping the sample machine to be tested, and the drop test machine capable of simulating continuous drop also includes a driving mechanism 3 , the support rod group 4 and the eccentric wheel group 5, the power output end of the driving mechanism 3 is connected to the power output end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com