Rotor house, magnetic steel module and rotor assembly

A rotor and module technology, applied in the direction of electric components, magnetic circuits, electrical components, etc., can solve the problems of high processing cost of rotor components and weak fixing of magnetic steel modules, so as to avoid the risk of loosening, simple structure, and high efficiency. The effect of installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

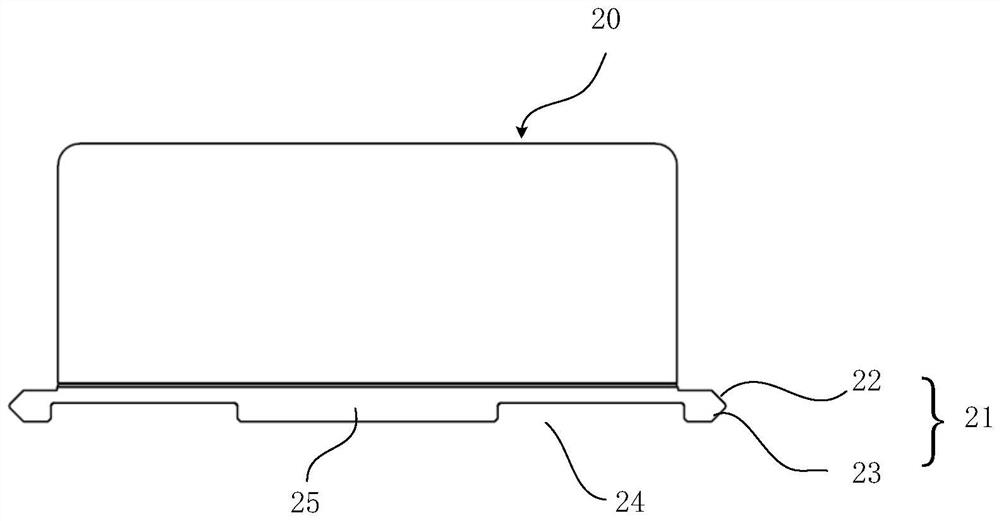

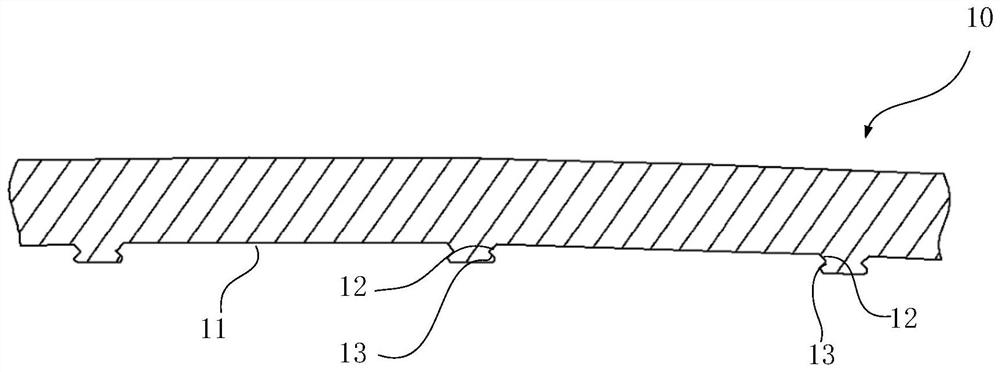

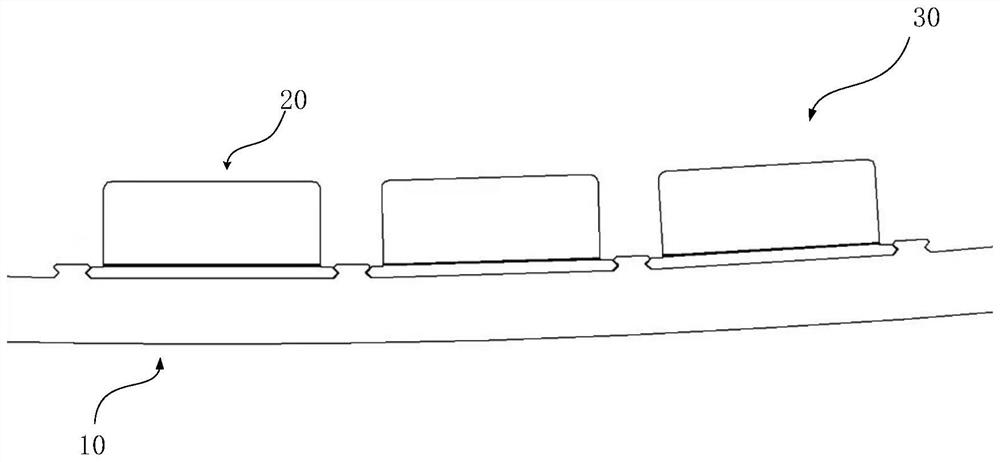

[0057] like Figure 1 to Figure 7As shown, this embodiment provides a rotor assembly 30 , the rotor assembly 30 includes a magnetic steel module 20 and a rotor house 10 , the magnetic steel module 20 is fixed on the rotor house 10 , and the magnetic steel module 20 includes a magnetic steel module 20 and the rotor house 10 . The base plate 25 in contact with the yoke surface, the base plate 25 is made of magnetically conductive material, and the magnetic steel module 20 also includes a cover plate, a magnetic steel and a magnetic steel frame, wherein the cover plate is made of a non-magnetically conductive material, and the magnetic steel frame, The cover plate and the base plate 25 form a closed space for accommodating the magnetic steel. The number of the magnetic steel is at least two. With the above structure, the closed space can protect and prevent the permanent magnets and silicon steel parts.

[0058] In this embodiment, the yoke surface of the rotor house 10 is provid...

Embodiment 2

[0065] like Figure 8 to Figure 9 As shown, Embodiment 2 provides a rotor assembly 30, which is different from Embodiment 1 in that the end faces of the ends on both sides of the slot 11 on the yoke surface of the rotor house 10 are semicircular arc surfaces. The semicircular arc surface of one end portion is symmetrically arranged with the semicircular arc surface of the other end portion. The above-mentioned semi-circular arc groove 24 can be customized for a tool with a corresponding symmetrical angle during the manufacturing process. Compared with the T-shaped groove and the dovetail groove, the cutting edge angle of the tool is convenient for cutting, the reaction force that the tool bears is small, and the cutting force is large. , high feed speed and low processing cost.

[0066] It should be noted that the present invention is not limited to the solution in which the ends of the slots or the protrusions are triangular cross-sections and semi-circular arcs, as long as ...

Embodiment 3

[0068] like Figure 10 As shown, Embodiment 3 provides a rotor assembly 30, which is different from Embodiment 1 and Embodiment 2 above in that the protrusion 21 of the base plate 25 of the magnetic steel module 20 does not completely extend from one end of the rotor house 10 along its axis. direction extends to the other end, specifically, as Figure 10 As shown, the protrusions 21 are provided on both sides of the base plate 25, and each side of the base plate 25 is provided with two protrusions 21, and the two protrusions 21 are respectively provided at both ends of the side, and the protrusions 21 The radial protrusions are perpendicular to the rotor housing 10 . It should be noted that the arrangement structure of the protrusions 21 can be adjusted adaptively according to actual needs, which is not specifically limited here.

[0069] To sum up, the present invention adopts the configuration of the protrusions 21 of the base plate 25 of the magnetic steel module 20 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com