Cable joint connection structure and connection method

A connection structure and cable joint technology, applied in welding/welding connection, connection, clamping/spring connection, etc., can solve the problems of inconvenient operation, looseness and poor connection reliability of the connection between the cable joint and the cable wire, and achieve the connection reliability. Good, easy to connect and operate, to avoid the effect of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

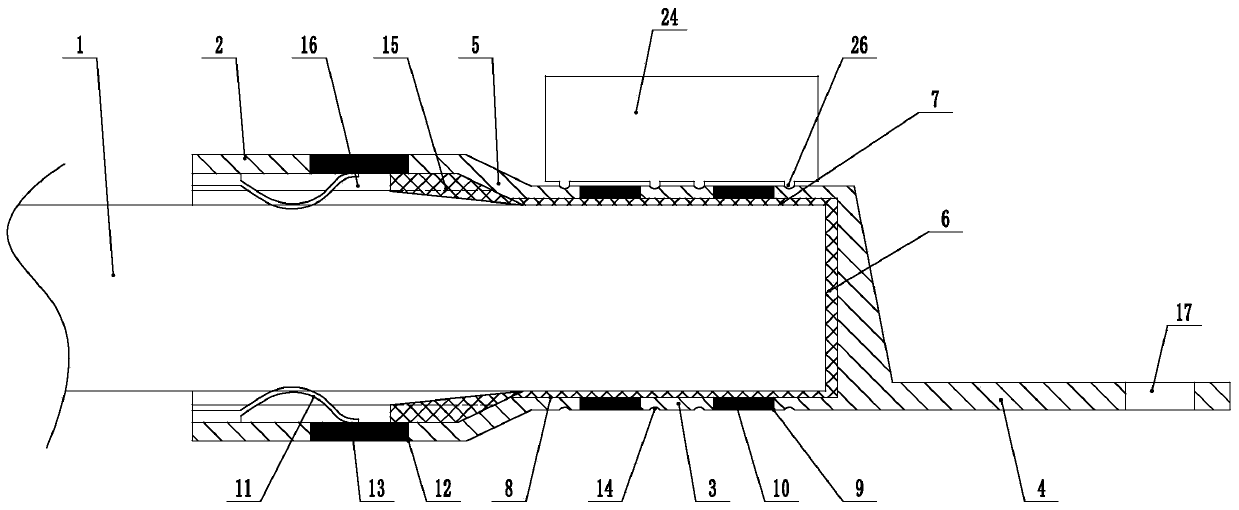

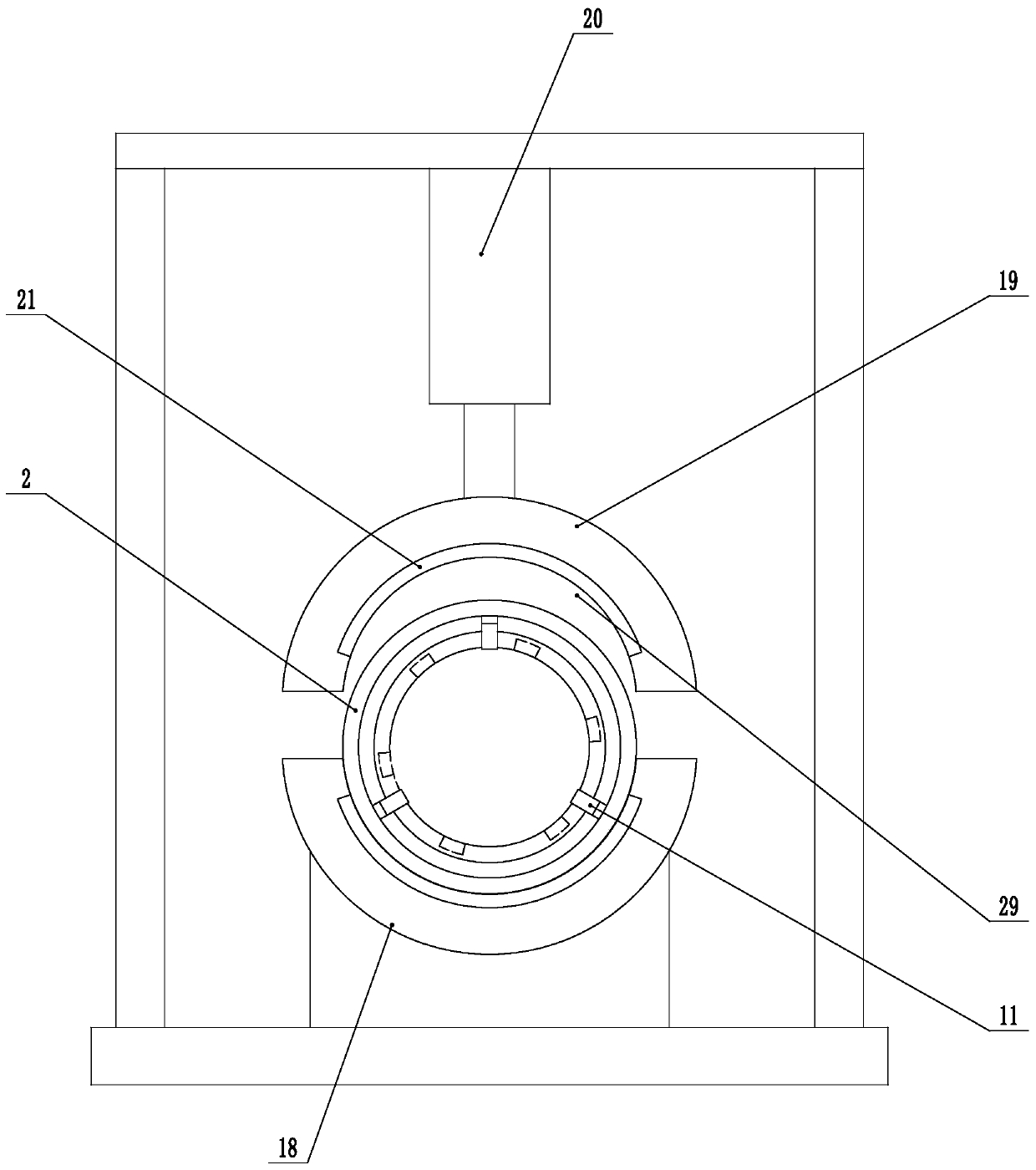

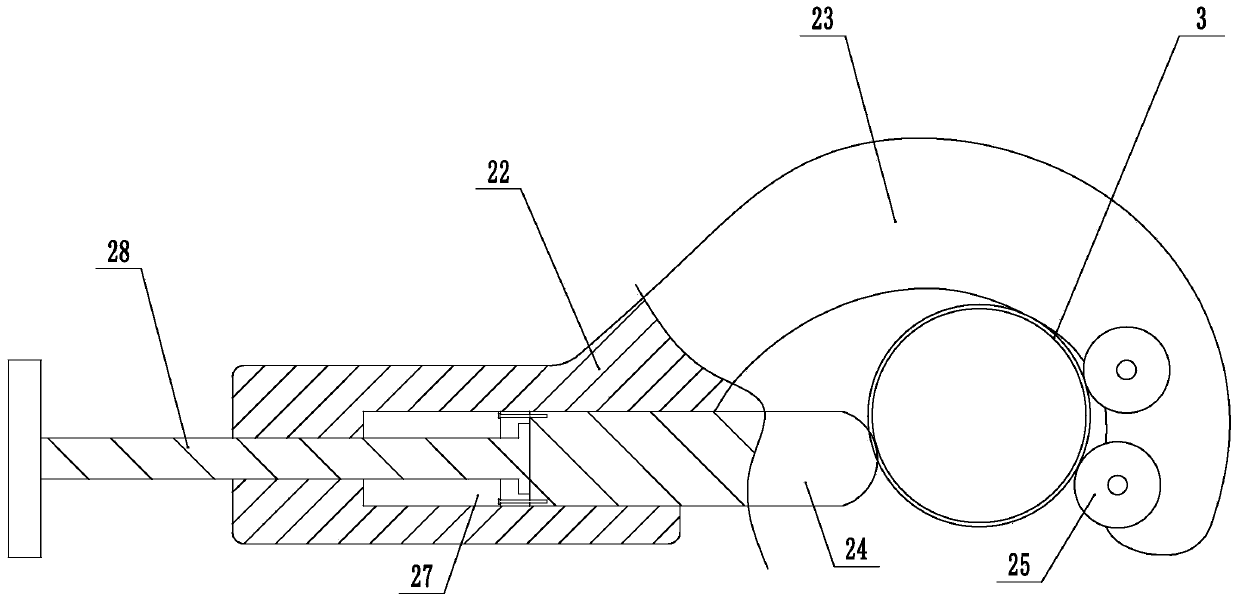

[0020] Embodiment: a kind of cable joint connection structure (see attached figure 1 ), including the connector body, the cable 1, the connector body is provided with a large-diameter tube 2, a small-diameter tube 3, and a lug 4. A transition ring 5, a solder frame is installed in the small-diameter tube, the solder frame includes a base 6, a number of support bars 7 connected to the base, and a number of axially arranged slots 8 are arranged on the inner wall of the small-diameter tube corresponding to the support bars. Adapted and inserted in the slot, the base is placed at the bottom of the small-diameter cylinder, a number of small-diameter solder baths 9 connected to the slot are provided on the outer wall of the small-diameter cylinder, and small-diameter solder blocks 10 are installed in the small-diameter solder bath; uniformly distributed on the inner wall of the large-diameter cylinder Several clamping shrapnels 11 arched inward are installed. One end of the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com