Torque wrench

A torque wrench and wrench head technology, applied in the field of torque wrenches, can solve problems such as low work efficiency, loose bolts, and complicated operation, and achieve the effects of easy inspection, improved service life, and simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

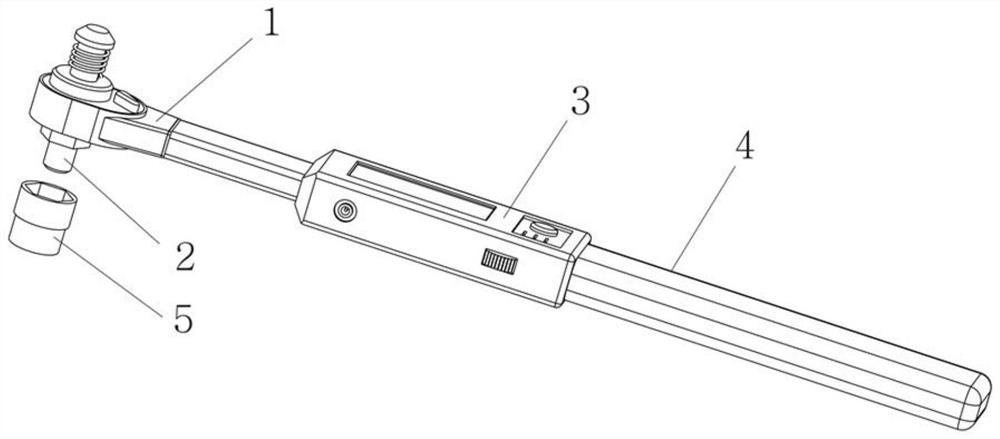

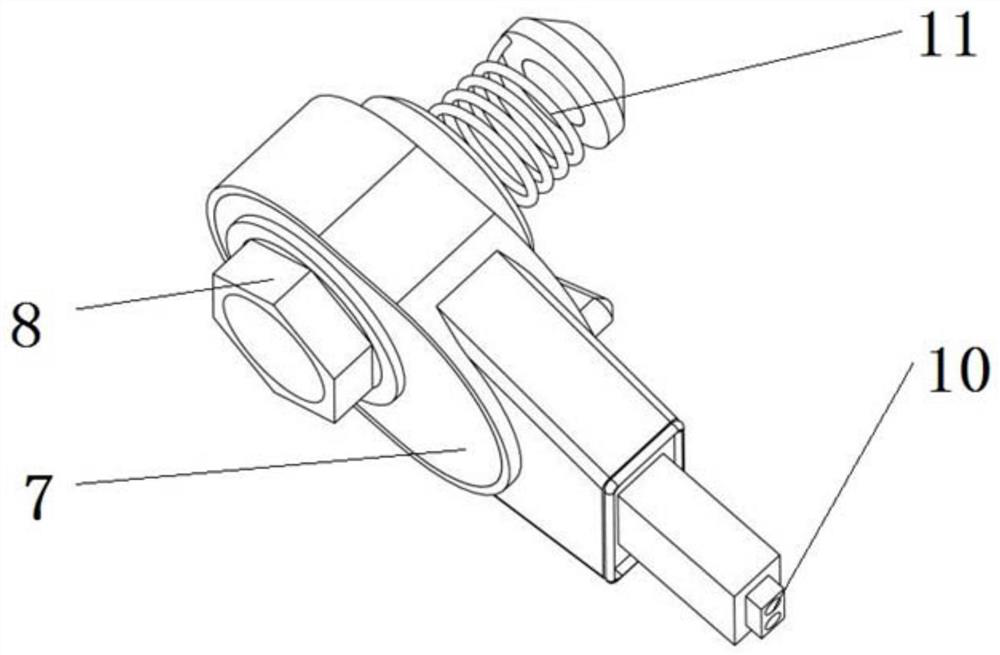

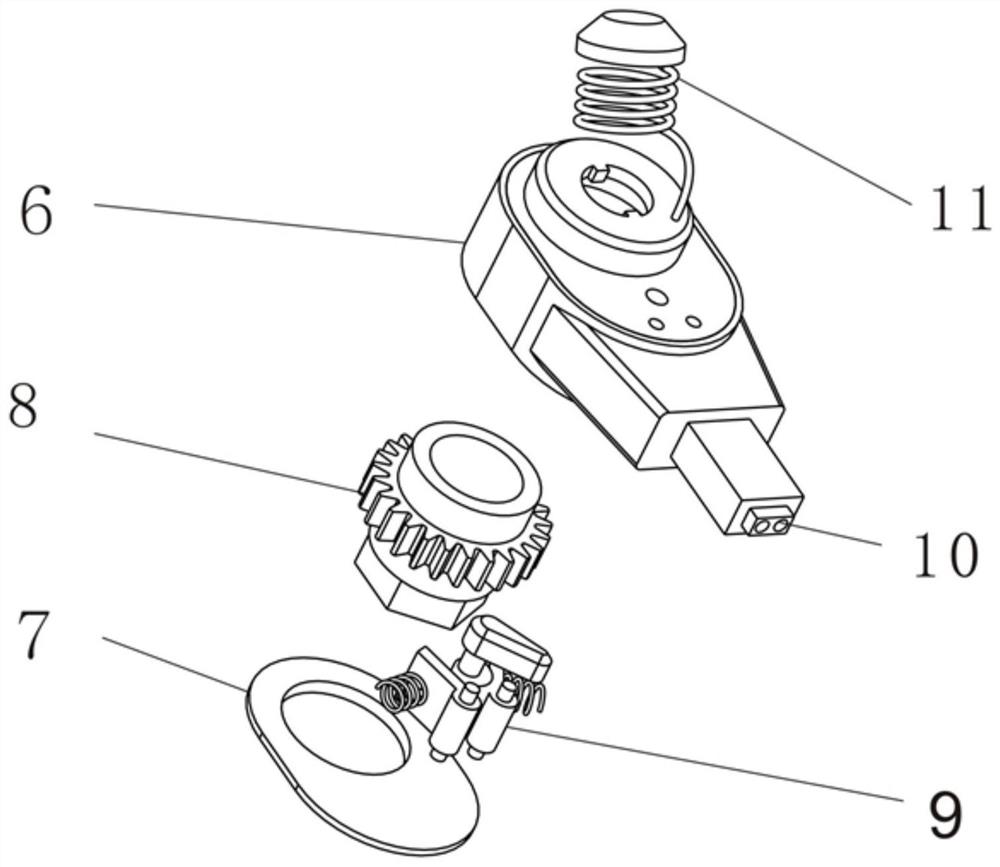

[0036] The present invention provides a torque wrench, which includes a wrench rod 4 and a wrench head 1 connected to each other. A sleeve 5 and a mark applicator 2 are assembled on the wrench head 1, and the mark applicator 2 is assembled in the mounting hole of the wrench head 1. Inside, the bottom protrudes into the hollow cavity through which the casing 5 passes, and may reciprocate along the axis of the casing 5 to print marks.

[0037] A kind of torque wrench provided by the invention, such as Figure 1 to Figure 13 As shown, it includes a wrench head 1 and a wrench rod 4. The rear end of the wrench head 1 is connected to the front end of the wrench rod 4, which can be integrally formed or connected to each other in a conventional way to form an integral structure, and can be disassembled. The size of the bolt is to replace the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com