Soil turning device for fruit tree seedling planting and using method thereof

A technology of fruit trees and racks, applied in the direction of application, shovel, plow, etc., can solve the problems of blade breakage, affect the quality of turning soil, and cannot remove gravel, etc., to achieve the effect of facilitating reclamation and cultivation, preventing breakage, and facilitating planting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

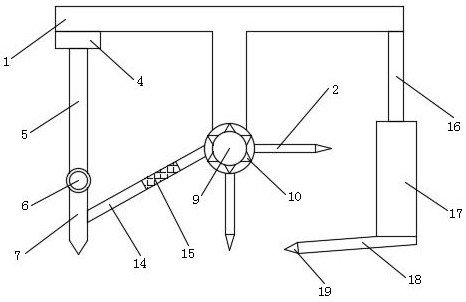

[0039] S1. Gravel contact: During the operation of the frame 1, it drives the connecting rod 4 to move forward, and then drives the bracket 5 and the baffle 7 to move forward. When the baffle 7 encounters gravel, the baffle 7 moves around The rotating shaft 6 is folded backward to contact the blocked gravel, and the collision force generated by the gravel acts on the baffle 7, which is convenient for subsequent use;

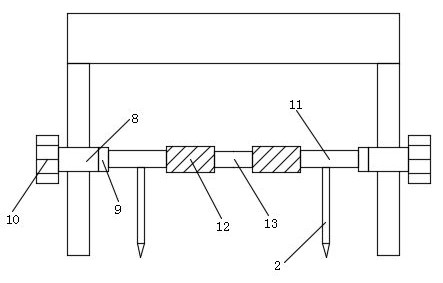

[0040] S2. Turning the soil: In step S1, 30% of the soil is loosened, and the gear 10 is driven to rotate by an external transmission device. The rotation of the gear 10 drives the support rod 11, the corrugated rubber 12 and the blade 2 to rotate, and the rotation speed is 30r / min. The rotation of the blade 2 effectively turns over the soil, achieving an effective turning over of the remaining 70% of the soil;

[0041]S3. Avoidance of gravel: In step S1, the baffle 7 meets the gravel and folds backward, thereby driving the folding plate 14 to shift, and the move...

no. 2 example

[0045] S1. Gravel contact: During the operation of the frame 1, it drives the connecting rod 4 to move forward, and then drives the bracket 5 and the baffle 7 to move forward. When the baffle 7 encounters gravel, the baffle 7 moves around The rotating shaft 6 is folded backward to contact the blocked gravel, and the collision force generated by the gravel acts on the baffle 7, which is convenient for subsequent use;

[0046] S2. Turning the soil: In step S1, 45% of the soil is loosened, and an external transmission device is used to drive the gear 10 to rotate. The rotation of the gear 10 drives the support rod 11, the corrugated rubber 12 and the blade 2 to rotate, and the rotation speed is 40r / min. The rotation of the blade 2 effectively turns over the soil, achieving an effective turnover process for the remaining 55% of the soil;

[0047] S3. Avoidance of gravel: In step S1, the baffle 7 meets the gravel and folds backward, thereby driving the folding plate 14 to shift, an...

no. 3 example

[0051] S1. Gravel contact: During the operation of the frame 1, it drives the connecting rod 4 to move forward, and then drives the bracket 5 and the baffle 7 to move forward. When the baffle 7 encounters gravel, the baffle 7 moves around The rotating shaft 6 is folded backward to contact the blocked gravel, and the collision force generated by the gravel acts on the baffle 7, which is convenient for subsequent use;

[0052] S2. Turning the soil: In step S1, 60% of the soil is loosened, and the gear 10 is driven to rotate by an external transmission device. The rotation of the gear 10 drives the support rod 11, the corrugated rubber 12 and the blade 2 to rotate, and the rotation speed is 45r / min. The rotation of the blade 2 effectively turns over the soil, achieving an effective turnover process for the remaining 40% of the soil;

[0053] S3. Avoidance of gravel: In step S1, the baffle 7 meets the gravel and folds backward, thereby driving the folding plate 14 to shift, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com