Machining arm

A mechanical processing and arm technology, applied in the direction of manipulator, control mechanical energy, claw arm, etc., can solve the problem that the length of the manipulator cannot be adjusted automatically, and achieve the effect of simple structure, small size, and precise and controllable length change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

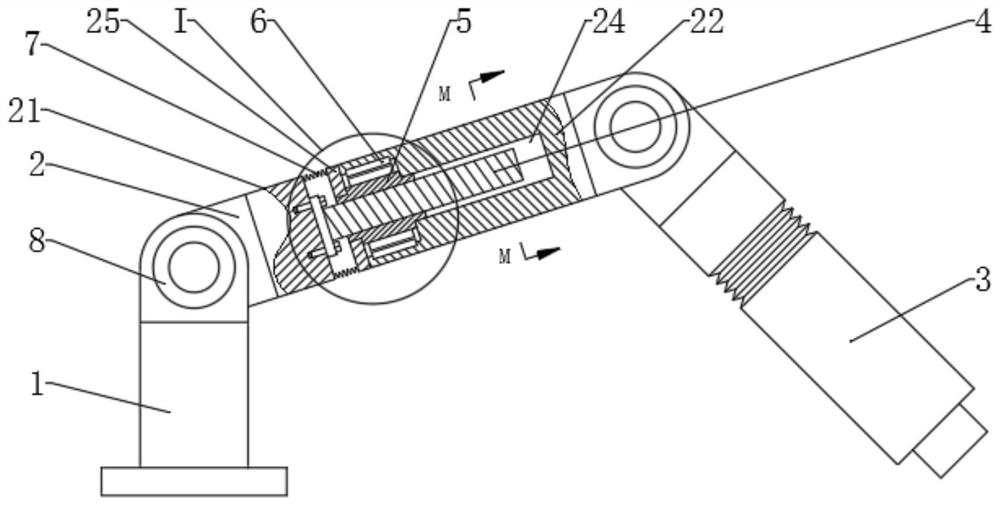

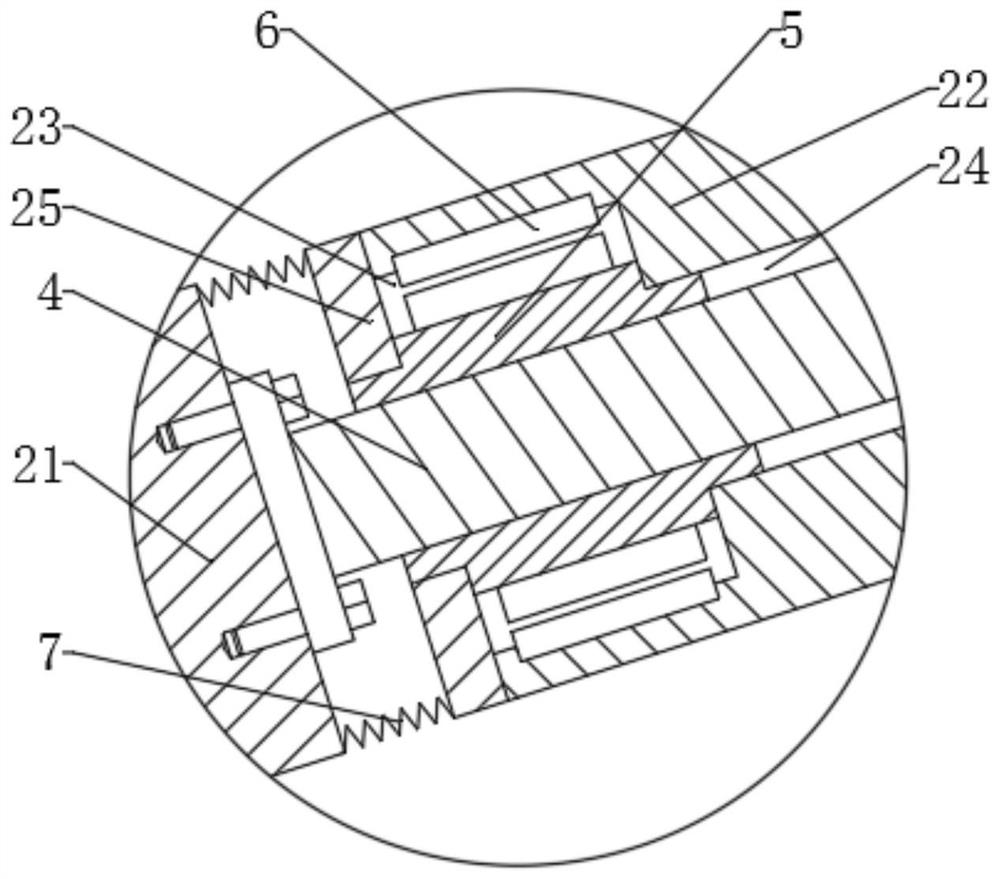

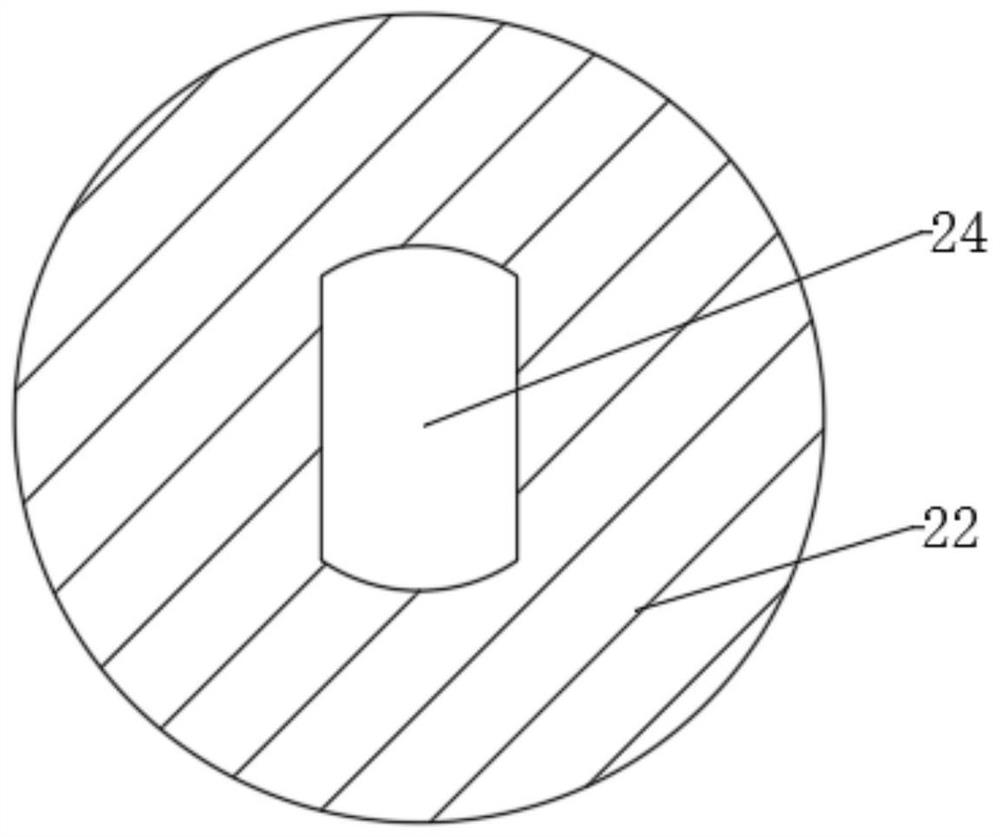

[0023] Depend on Figure 1 ~ Figure 3 As shown, a mechanical processing arm includes a base 1, a first arm 2 and a second arm 3, the base 1, the first arm 2 and the second arm 3 are hinged in sequence, and the base 1, the second arm The hinge shafts of the first arm 2 and the second arm 3 are connected with a rotary motor 8, the first arm 2 and the second arm 3 have the same structure, and the first arm 2 includes a first connecting seat 21 and a second connecting seat 21. Seat 22, the threaded rod 4 is fixedly connected to the first connecting seat 21, the second connecting seat 22 is provided with a rotor chamber 23 and a screw chamber 24, the rotor chamber 23 is provided with a rotor tube 5 capable of rotating around its own axis, and the rotor tube 5 is a magnetic material, the rotor tube 5 is provided with a magnetic steel 53, the rotor tube 5 is sleeved on the threaded rod 4, and the rotor cavity 23 is also provided with a stator winding 6 for driving the rotor tube 5 to...

Embodiment 2

[0033] Depend on Figure 1 ~ Figure 3 As shown, a mechanical processing arm includes a base 1, a first arm 2 and a second arm 3, the base 1, the first arm 2 and the second arm 3 are sequentially hinged, and the base 1, the second arm The hinge shafts of the first arm 2 and the second arm 3 are connected with a rotary motor 8, the first arm 2 and the second arm 3 have the same structure, and the first arm 2 includes a first connecting seat 21 and a second connecting seat 21. Seat 22, the threaded rod 4 is fixedly connected to the first connecting seat 21, the second connecting seat 22 is provided with a rotor chamber 23 and a screw chamber 24, the rotor chamber 23 is provided with a rotor tube 5 capable of rotating around its own axis, and the rotor tube 5 is a magnetic material, the rotor tube 5 is provided with a magnetic steel 53, the rotor tube 5 is sleeved on the threaded rod 4, and the rotor cavity 23 is also provided with a stator winding 6 for driving the rotor tube 5 t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap