Plate conveying and transporting robot

A robot and plate feeding technology, applied in transportation and packaging, motor vehicles, etc., can solve the problems of affecting plate position accuracy, affecting transportation, and high cost of robots, and achieve the effect of improving transportation effect, reducing production cost and ensuring position accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

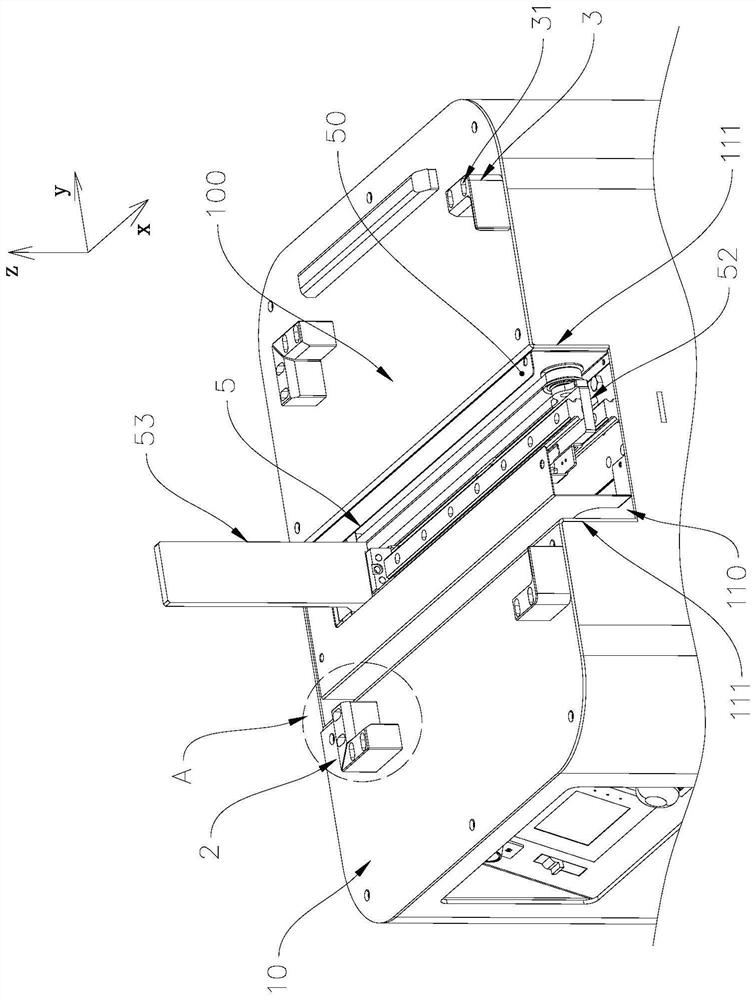

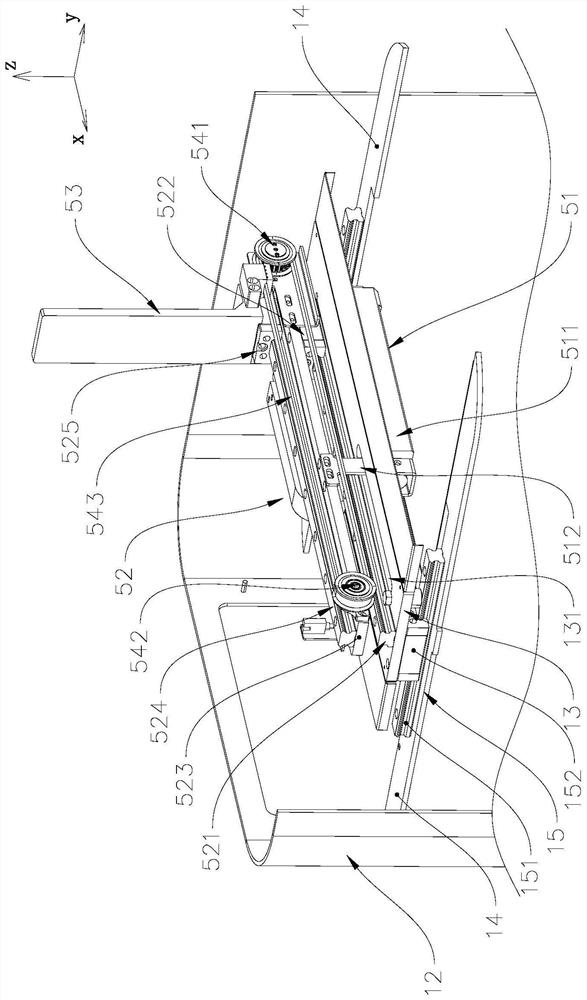

[0033] see figure 1 with figure 2 , figure 1 It is a structural diagram of an embodiment of the board delivery robot of the present invention, figure 2 It is a structural diagram of a hidden shelf frame for an embodiment of the board delivery and transportation robot of the present invention. A unified rectangular space coordinate system is established in each drawing, wherein the x-axis direction refers to the first horizontal direction, the x-axis direction refers to the second horizontal direction, and the z-axis direction refers to the height direction. The plate feeding transport robot includes a body 1, a drive wheel set 19, a limit structure 2, a limit structure 3, a push device 5 and a shelf frame 6, and the drive wheel set 19 is fixedly installed on the bottom of the body 1, and the top of the body 1 has a bearing The platform 10, the two space-limiting structures 2 and the two space-limiting structures 3 are locked on the bearing platform 10 by bolts, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com