Preparation method of tetravinylsilane

A technology of tetravinylsilane and vinyl chloride, applied in the field of preparation of tetravinylsilane, can solve the problems of insufficient environmental protection, complicated use of raw materials, poor controllability, etc., and achieves easy expansion of production, single raw material, and few post-processing steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

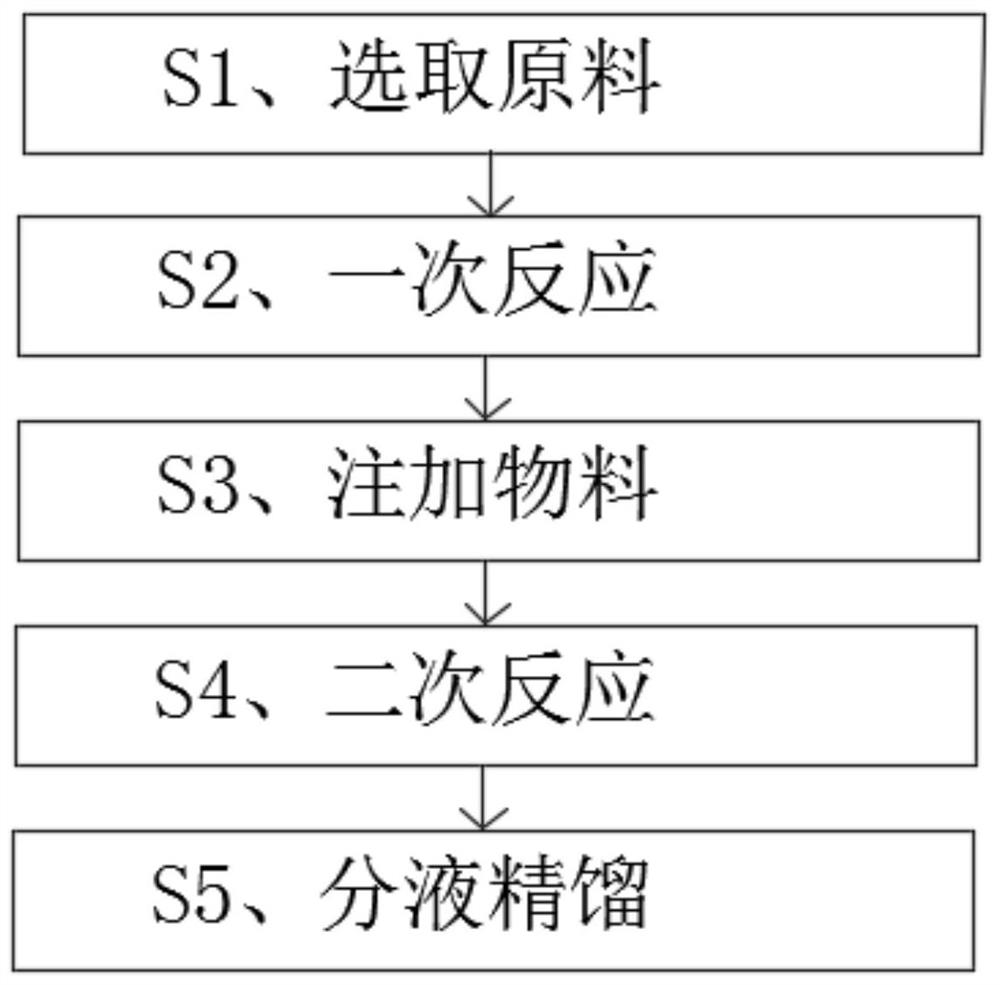

[0027] refer to figure 1 , a preparation method of tetravinylsilane, specifically comprising the following steps:

[0028] S1. Select raw materials: select the following weight components for later use: 280 parts of vinyl chloride, 1900 parts of tetrahydrofuran, 110 parts of magnesium chips, 800 parts of silicon tetrachloride, and 680 parts of water;

[0029] S2. Primary reaction: Add tetrahydrofuran and magnesium chips into the No. 1 reactor, mix and stir them evenly with a stirrer, then heat the temperature inside the reactor to 70°C, and then feed vinyl chloride gas into the No. 1 reactor. Then keep warm for 3h to obtain Grignard agent;

[0030] S3, adding materials: adding silicon tetrachloride to the No. 2 reactor;

[0031] S4. Secondary reaction: add the Grignard agent in the No. 1 reactor after the first reaction of S2 to the No. 2 reactor, and control the temperature in the No. 2 reactor to maintain at -1°C;

[0032] S5. Separation and rectification: heat the temper...

Embodiment 2

[0039] refer to figure 1 , a preparation method of tetravinylsilane, specifically comprising the following steps:

[0040] S1. Select raw materials: select the following weight components for later use: 290 parts of vinyl chloride, 2000 parts of tetrahydrofuran, 130 parts of magnesium chips, 800 parts of silicon tetrachloride, and 680 parts of water;

[0041] S2. One reaction: add tetrahydrofuran and magnesium chips into the No. 1 reactor, mix and stir them evenly with a stirrer, then heat the temperature in the reactor to 76°C, and then feed vinyl chloride gas into the No. 1 reactor. Then keep warm for 3h to obtain Grignard agent;

[0042] S3, adding materials: adding silicon tetrachloride to the No. 2 reactor;

[0043] S4. Secondary reaction: add the Grignard agent in the No. 1 reactor after the primary reaction of S2 dropwise into the No. 2 reactor, and control the temperature in the No. 2 reactor to maintain at 0°C;

[0044] S5. Separation and rectification: heat the te...

Embodiment 3

[0049] refer to figure 1 , a preparation method of tetravinylsilane, specifically comprising the following steps:

[0050] S1. Select raw materials: select the following weight components for use: 300 parts of vinyl chloride, 2000 parts of tetrahydrofuran, 120 parts of magnesium chips, 816 parts of silicon tetrachloride, and 700 parts of water;

[0051] S2. One reaction: add tetrahydrofuran and magnesium chips into the No. 1 reactor, mix and stir them evenly with a stirrer, then heat the temperature in the reactor to 76°C, and then feed vinyl chloride gas into the No. 1 reactor. Then keep warm for 3h to obtain Grignard agent;

[0052] S3, adding materials: adding silicon tetrachloride to the No. 2 reactor;

[0053] S4. Secondary reaction: add the Grignard agent in the No. 1 reactor after the primary reaction of S2 dropwise into the No. 2 reactor, and control the temperature in the No. 2 reactor to maintain at 0°C;

[0054] S5. Separation and rectification: heat the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap