Method and apparatus for air extraction in the area of a heating press

An air suction, hot press technology, applied in cleaning methods and utensils, chemical instruments and methods, applications, etc., can solve problems such as energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

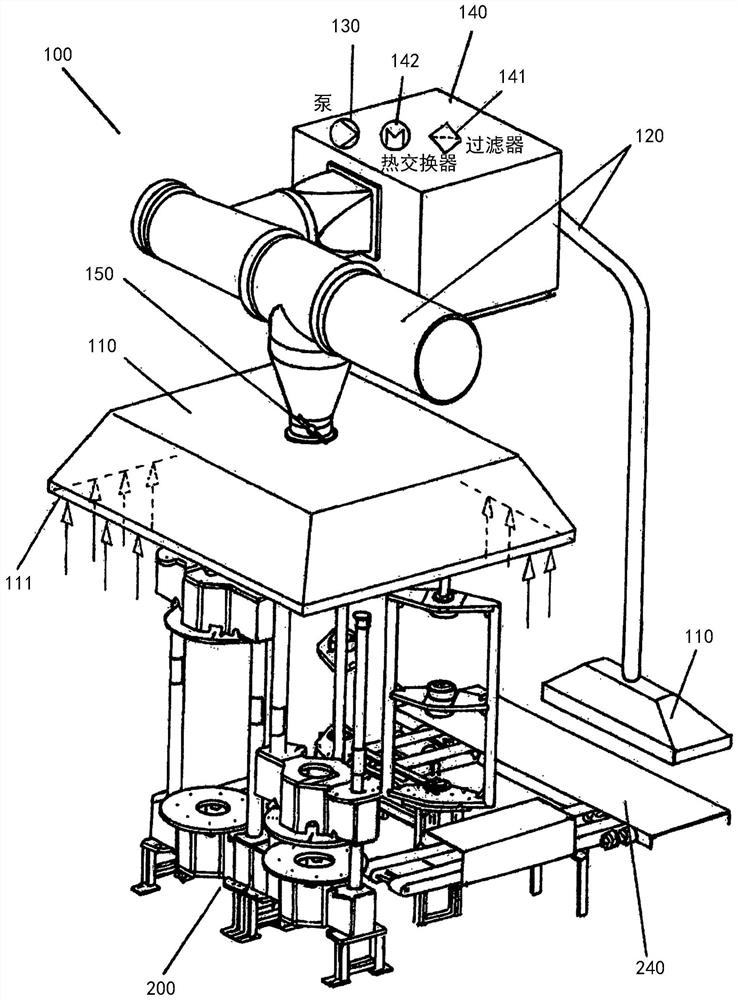

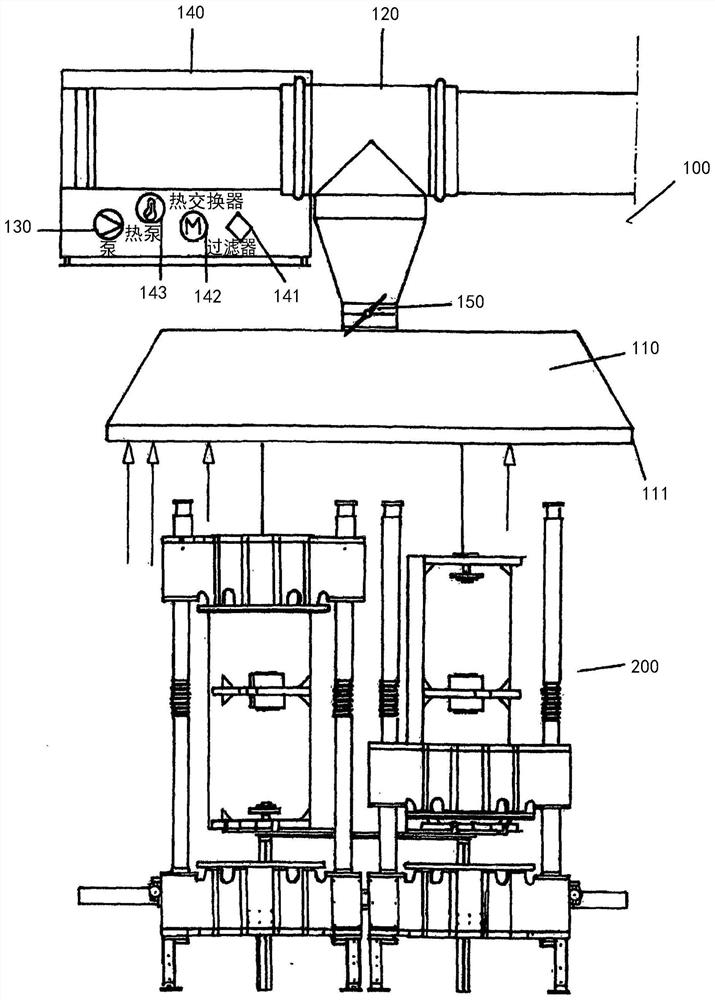

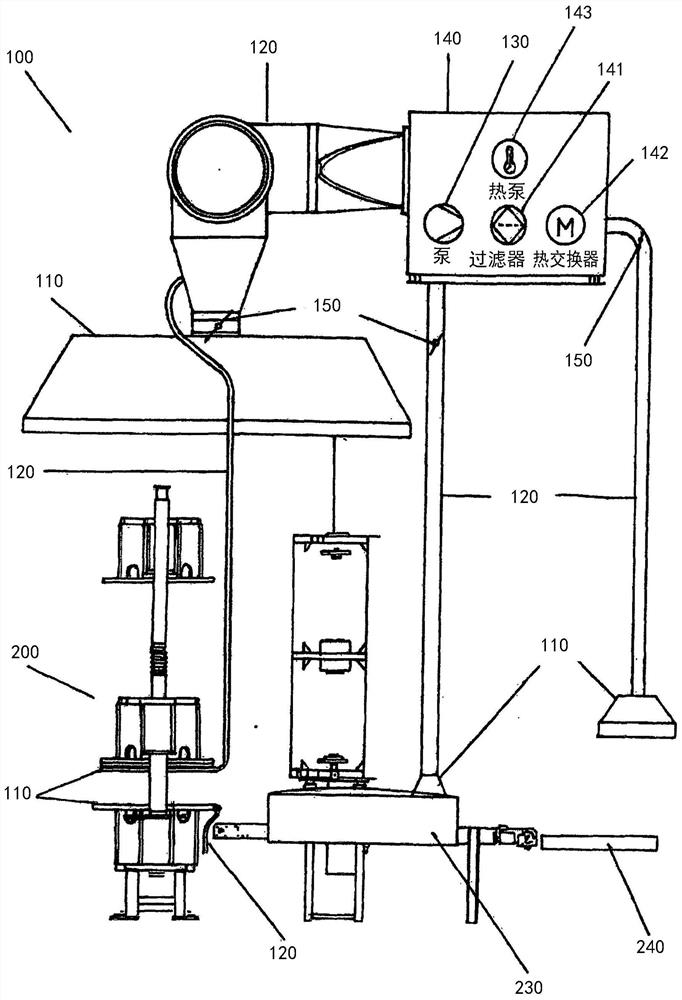

[0080] According to the device (100) according to the invention for air suction in figure 1 In the embodiment shown three-dimensionally, the suction takes place above and / or next to or behind the tire heat press (200). The tire heat press (200) is configured as a double tire heat press.

[0081] The device (100) for air suction has two suction devices (110) configured as suction guards, which are connected via a suction tube (120) to an air delivery device (130) configured as a pump. )connect.

[0082] In the region of the suction device ( 110 ), suction openings ( 111 ), which are designed, for example, as suction slits running around on the outer edge of the suction device ( 110 ), are arranged below.

[0083] In the joint area of the suction pipe (120) on the suction device (110) arranged centrally above the tire heat press (200), a flap (150) is arranged in the suction pipe (120), wherein , the suction tube (120) can be gradually opened and closed by means of the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com