A level electromagnetic casting device and method

An electromagnetic casting, the same level of technology, applied in the field of semi-continuous casting, can solve the problems of sufficient cooling of the ingot, refinement process, etc., to achieve the effects of controllable cooling, change of the microstructure of the melt, and easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

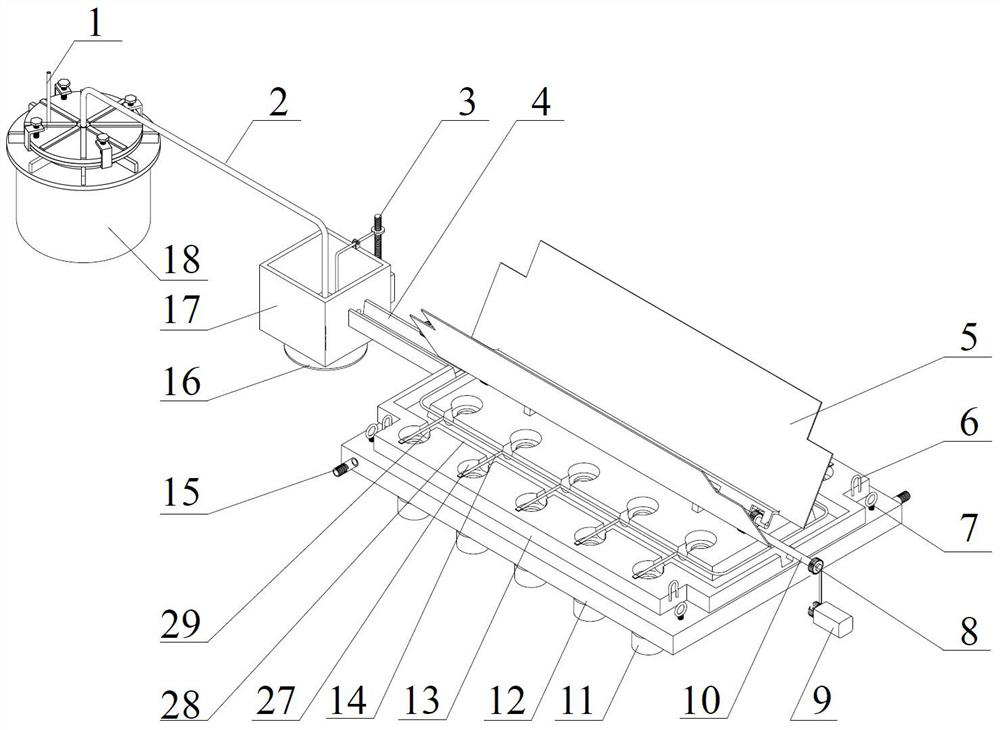

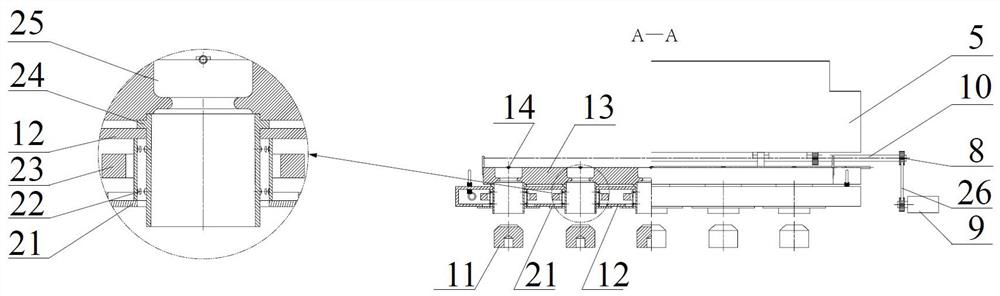

[0052] An electromagnetic casting device at the same level, used for casting magnesium alloy round billets, the specific structure refers to figure 1 , figure 2 and image 3 , the device mainly includes an induction melting furnace part, a tundish transfer part, a casting crystallizer part and other casting auxiliary tools. The cooling water tank can be hoisted and dropped by the cooling water tank suspension ring 7, and the cast flow plate 13 can be lifted and dropped by the cast flow plate suspension ring 6. First place the mold inner sleeve 24 in the reserved mold hole of the cooling water tank 12, and then place the casting flow plate 13 above it. The casting flow plate 13 has a casting flow plate inner flow channel 27, and the casting flow plate inner flow channel 27 comprises the hole that vertically runs through the casting flow plate, communicates with the casting flow plate main flow channel 28 through the casting flow plate shunt channel 29, the inner wall of the ...

Embodiment 2

[0064] The method is the same as in Example 1, except that the cast magnesium alloy model is AZ31, the ingot size is Φ320mm×5000mm, and there are 4 ingots.

[0065] The crystallizer inner sleeve 24 is made of aluminum alloy with a wall thickness of 20mm. Reinforcing ribs are provided outside the mold inner sleeve. The height of the mold inner sleeve is 180mm, the inner diameter of the top is 300mm, the inner diameter of the bottom is 302mm, and the slope of the inner wall from the top to the bottom is 0.32° .

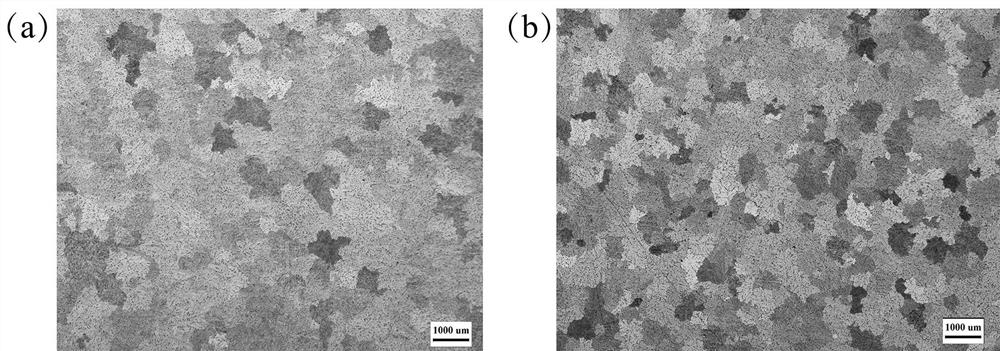

[0066] The dummy head adopts attached Figure 4 (b) The structure shown.

[0067] The inner diameter of the protective gas ring 14 is 8mm, and the spacing of the air outlet holes is evenly distributed at 15mm; the protective gas is SF 6 +CO 2 The mixed gas, the air pressure is 0.020MPa; the preheating temperature is 350℃, and the cooling water volume is 100m 3 / h, the water temperature is 30°C; the excitation current intensity is 70~80A (peak current is about 200~22...

Embodiment 3

[0070] The cast flow plate covering device and the shielding gas ring 14 composed of the cover plate 5, the gear 8, the connecting rod 10, the hinge 26 and the horizontal driving motor 9 in the device in the first embodiment are omitted. The other parts of the device are the same as in Example 1.

[0071] Method is with embodiment 1, and difference is characterized in that:

[0072] In the casting method, the following steps related to the casting flow plate covering device and the protective gas ring are omitted: start the horizontal drive motor 9 to drive the cover plate 5 to cover the surface of the casting flow plate 13, pass the protective gas into the protective gas ring 14, and stop the flow Protective gas.

[0073] The casting billet is aluminum alloy, the model is 6063, the size of the ingot is Φ300mm×5000mm, and there are 4 pieces.

[0074] The crystallizer inner sleeve 24 is made of red copper with a wall thickness of 8 mm. The mold inner sleeve has a height of 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com