A five-degree-of-freedom hybrid robot mold polishing system and method

A robot with a degree of freedom, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, manipulators, etc., can solve the problem of inability to process the mold surface, and it is difficult to accurately determine the position and orientation data of robot polishing equipment and the trajectory of tool positions, etc. problems, to achieve the effect of improving the poor quality of the polished surface, improving the quality and precision of the polished surface, and ensuring the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

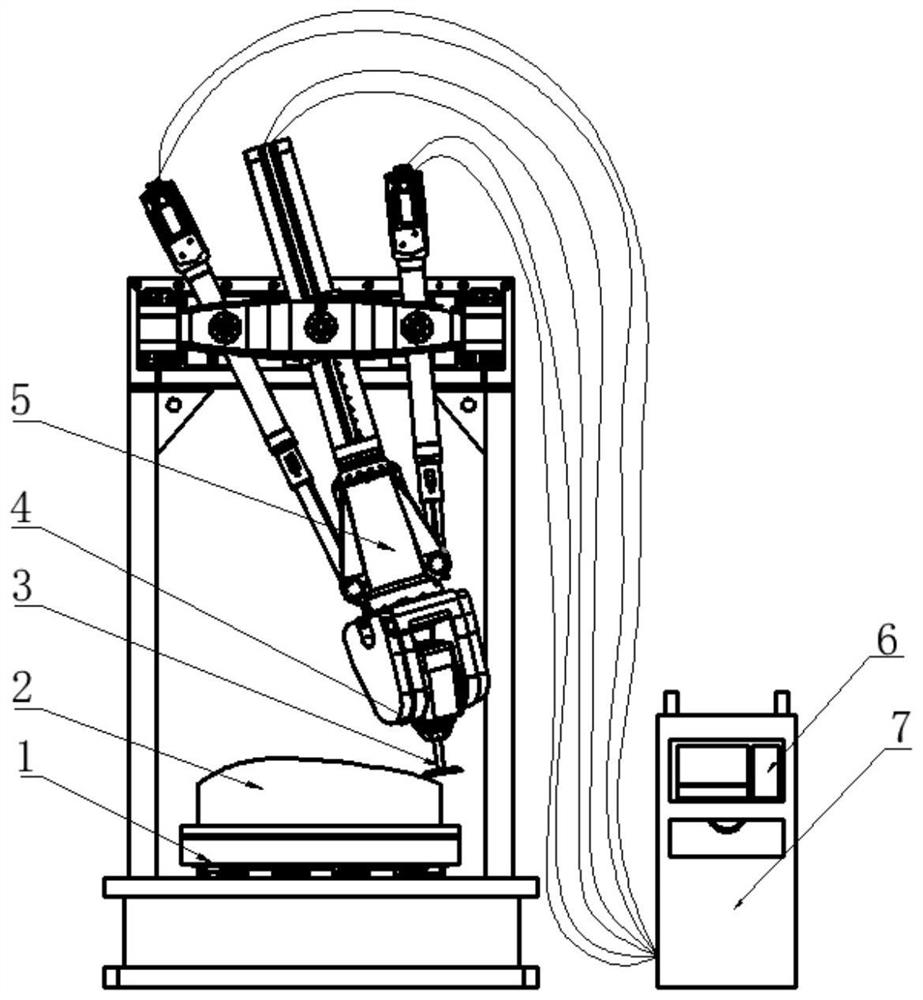

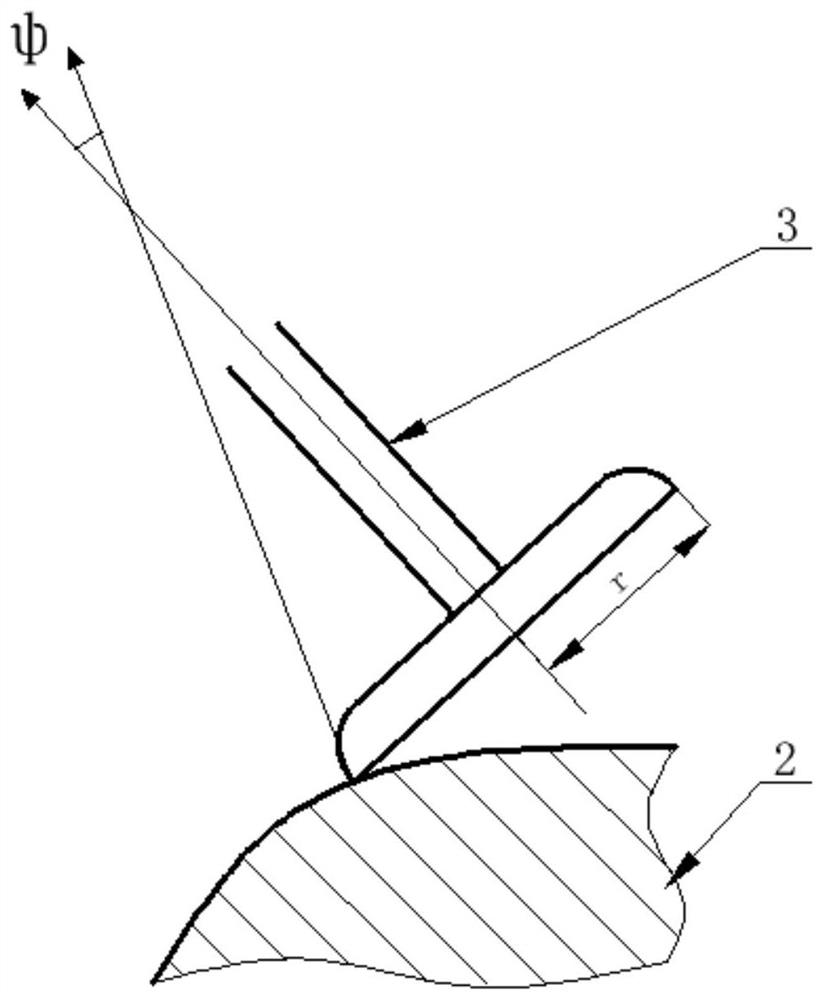

[0038] See Figure 1 to Figure 3 , a five-degree-of-freedom hybrid robot mold polishing method, the method comprises the following steps:

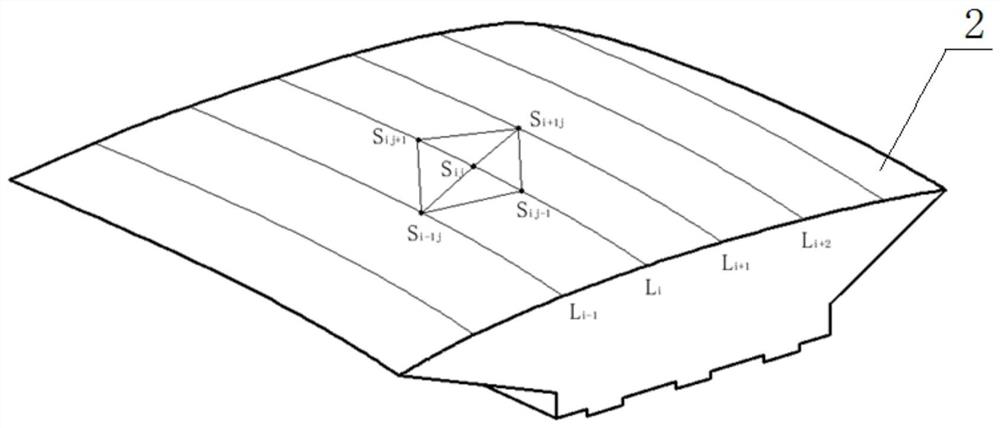

[0039]Step 1, use 3D CAD software to establish a 3D model of mold 2, and establish a workpiece coordinate system based on the 3D CAD model drawing of mold 2; the 3D drawing software of mold 2 can be established by Por / E, MasterCAM, UG, CAXA manufacturing engineers and other 3D drawing software Model, set a polishing path parallel to the X-axis of the workpiece coordinate system in the three-dimensional model diagram, and then directly derive the position coordinates of each tool contact in the polishing path under the workpiece coordinate system by the three-dimensional drawing software.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com