A safety valve airtight test tool and test method

An airtight test and valve technology, which is applied in fluid tightness test, measuring device, machine/structural component test, etc. It can solve problems such as difficult sealing, inconvenient clamping, easy scratching of valves, etc., and achieves simple operation Convenience, improved test efficiency, and reduced test air leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

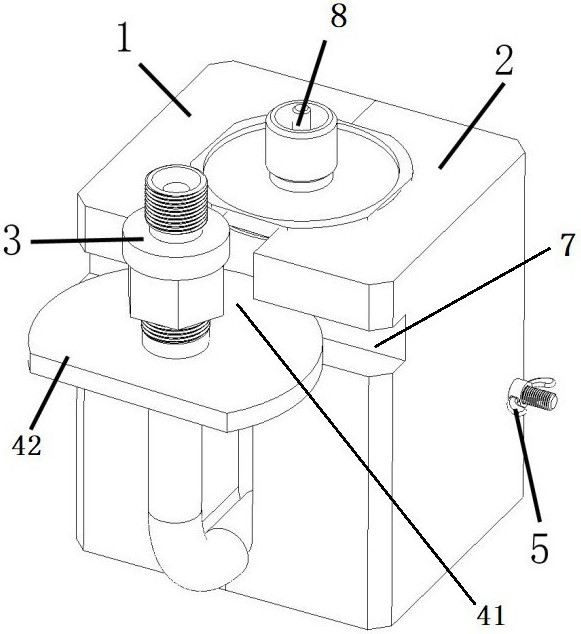

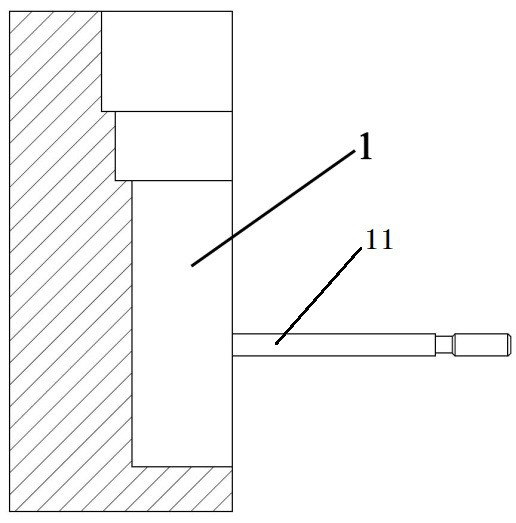

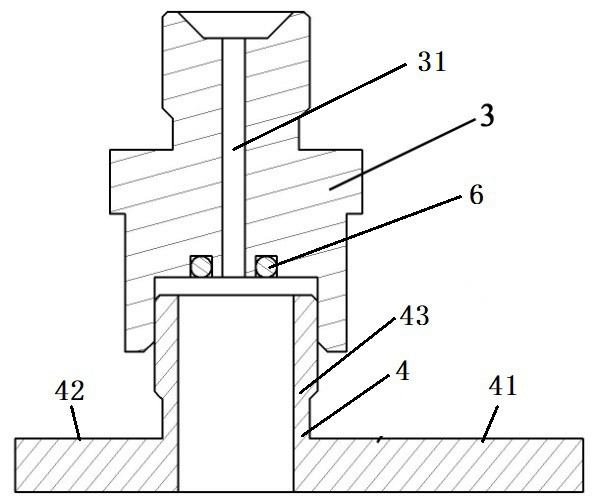

[0024] Such as figure 1 As shown, the present embodiment provides a safety valve airtight test tool, the safety valve 8 is provided with a U-shaped tube, and the airtight test tool includes a clamping member, a tight disc 4, and a nozzle 3, and the clamping member will The left half of the U-shaped tube is clamped, and the clamping member is provided with a horizontal clamping groove 7 on the side close to the right half of the U-shaped tube; , the round point of the disc body is provided with an upwardly protruding threaded nozzle 43, and the top tight disc 4 is sleeved on the opening of the right half of the U-shaped pipe through the threaded nozzle 43, wherein the superior arc section of the disc body is the long side 41, cut off One end of the inferior arc section is a short side 42. When the threaded nozzle 43 of the top tight disc 4 is placed on the opening of the right half of the U-shaped pipe, the long side 41 can be embedded in the slot 7, and the short side 42 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com