Nondestructive testing device for composite material

A non-destructive testing, composite material technology, applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problems of cumbersome, inconvenient, and single process, and achieve the effect of high flexibility, avoiding shaking or falling, and simple testing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

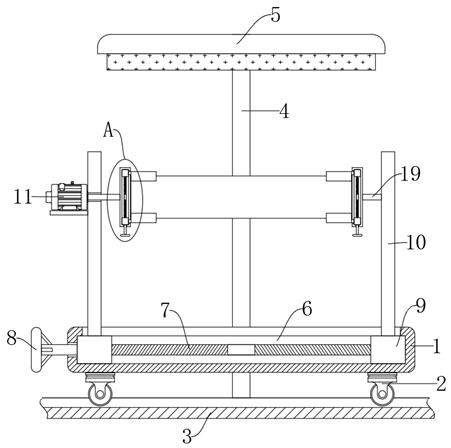

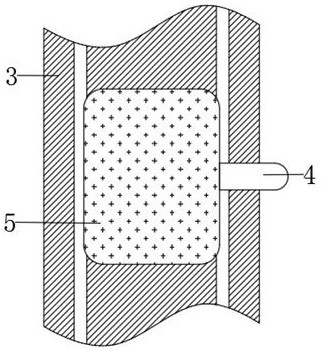

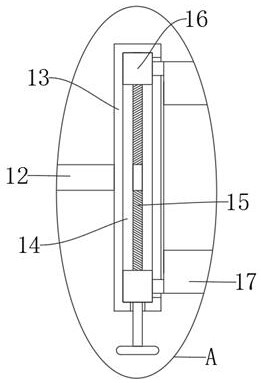

[0020] refer to Figure 1-4 , a non-destructive testing device for composite materials, comprising a fixed base 1, a plurality of pulleys 2 are fixedly installed on the side wall of the lower end of the fixed base 1, the lower ends of the plurality of pulleys 2 are jointly slidably connected with a slide rail 3, and the side walls of the slide rail 3 are fixed A connecting rod 4 is installed, and a probe 5 is fixedly installed on the upper end of the connecting rod 4. Through the setting of the pulley 2 and the slide rail 3, the fixed base 1 can be moved to the bottom of the probe 5 to realize the detection of materials;

[0021] The side wall of the fixed base 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com