An intelligent infrared and visible light dual-band camouflage film and its preparation method

A visible light, dual-band technology, applied in optics, filters, optical components, etc., can solve the problems of high phase transition point temperature, reduced phase transition point, low infrared emissivity, etc., and achieves a large range of infrared emissivity regulation, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

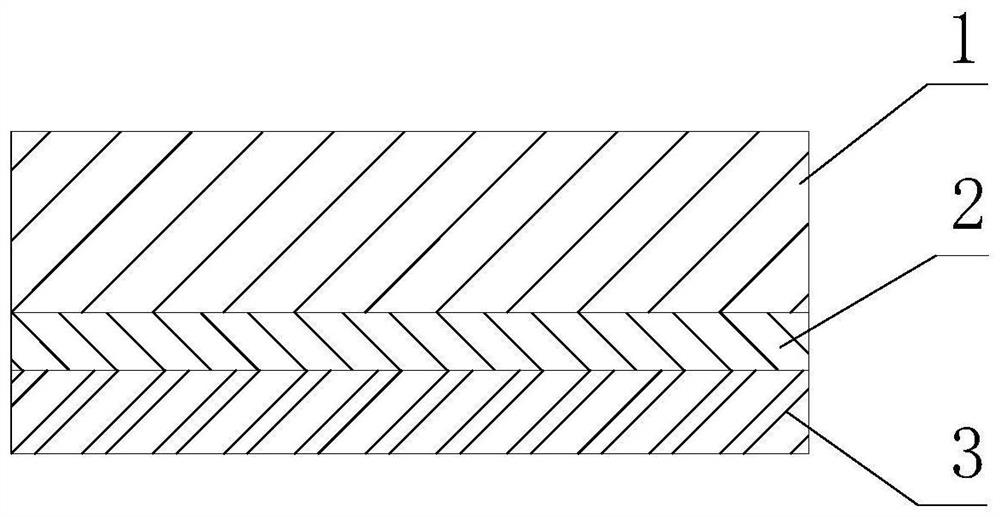

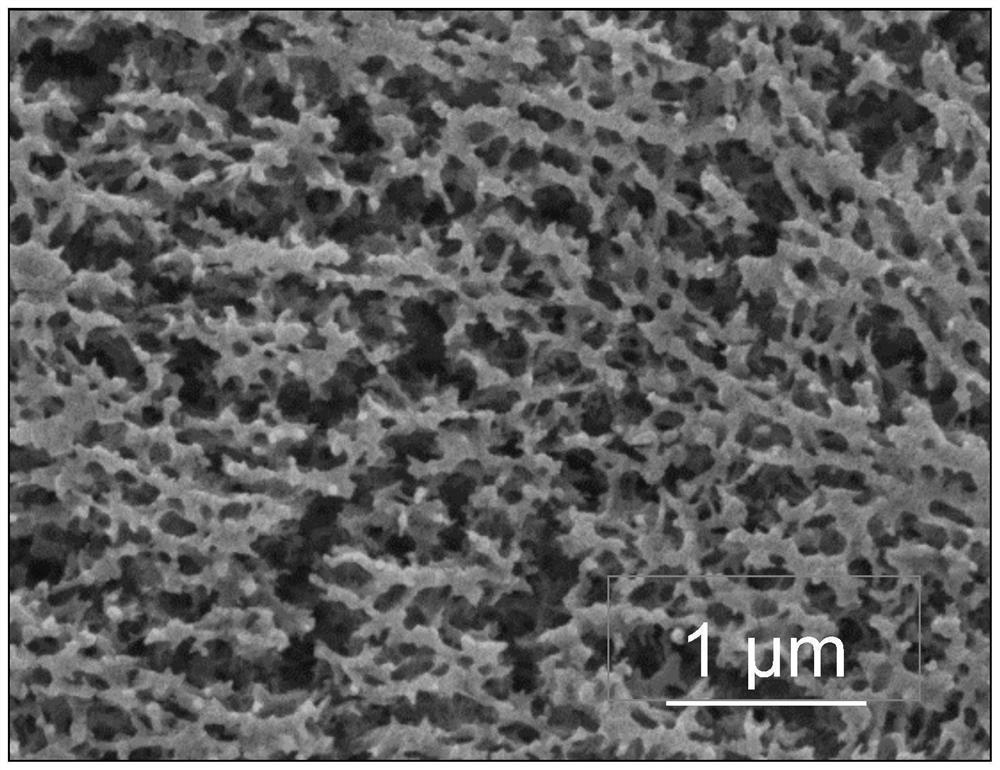

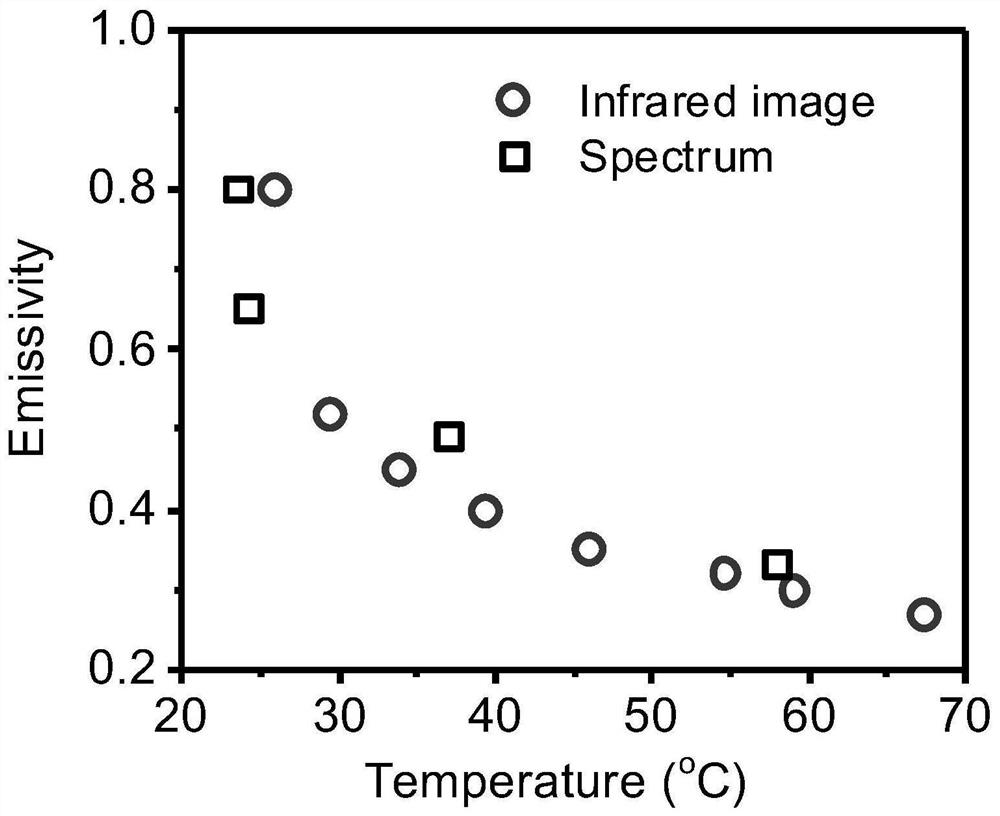

[0040] An intelligent infrared and visible light dual-band camouflage film, including an infrared high-reflection film layer, an infrared emissivity control layer (that is, the film has a two-layer structure), an infrared high-reflection film layer (bottom layer), and an infrared emissivity control layer (surface layer) Arranged from bottom to top, the infrared emissivity control layer is attached (that is: relying on hydrophilic groups to stick) on the infrared high-reflection film layer; the infrared high-reflection film layer (bottom layer) is a conventional film with a metal reflective layer deposited on the surface , with low infrared emissivity (attached image 3 ); the infrared emissivity control layer (surface layer) is a porous flexible composite membrane (attached to figure 1 ), which is transparent under visible light, thereby displaying the bottom color; the porous substrate is transparent in the infrared atmospheric window band, and the infrared characteristics a...

Embodiment 2

[0047] Such as figure 1 As shown, an intelligent infrared and visible light dual-band camouflage film includes an infrared high-reflection film layer, a visible light color control layer, an infrared emissivity control layer (that is, the film has a three-layer structure), an infrared high-reflection film layer (bottom layer), The visible light color control layer (middle layer) and the infrared emissivity control layer (surface layer) are arranged sequentially from bottom to top, the visible light color control layer 2 is coated on the infrared high reflection film layer 3, and the infrared emissivity control layer 1 is attached to (ie: Relying on the hydrophilic group to stick to) the visible light color control layer 2; wherein the infrared high reflective film layer (bottom layer) is a conventional film deposited with a metal reflective layer on the surface, which has a lower infrared emissivity (attached image 3 ); the visible light color control layer (intermediate lay...

Embodiment 3

[0055] It is basically the same as Example 1 or 2, except that: the preparation of the infrared high reflection film layer (bottom layer). The infrared high-reflection layer of the present invention adopts a stainless steel film with a thickness of 10 μm as a substrate, and metal gold is plated on it as a high-reflection layer.

[0056] The preparation steps of the above-mentioned infrared highly reflective film layer (bottom layer) are as follows: take a stainless steel film (flexible film) with a thickness of 10 μm, utilize magnetron sputtering to plate a gold film with a thickness of about 250nm on it, and its parameter is bias voltage 50V, power 50W, chamber internal air pressure 2.0Pa. Its infrared reflectance is 0.95; an infrared high reflective thin film layer (that is, a high reflective layer) is obtained.

[0057] Example 3:

[0058] It is basically the same as Example 1 or 2, except that: the preparation of the infrared high reflection film layer (bottom layer). T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com