Battery core continuous winding device and battery core continuous winding method

A winding device and cell technology, applied to non-aqueous electrolyte batteries, circuits, electrical components, etc., can solve the problem of low winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

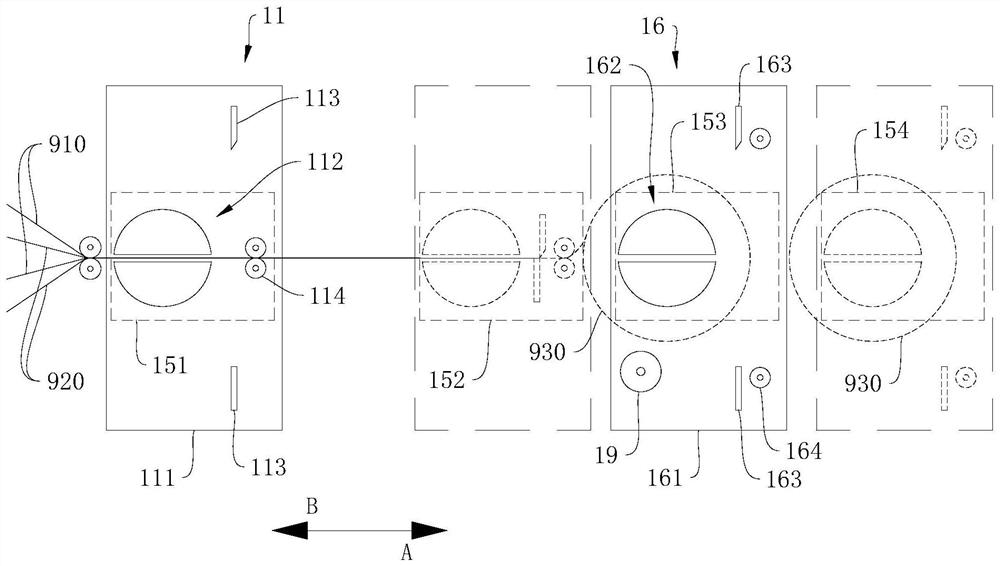

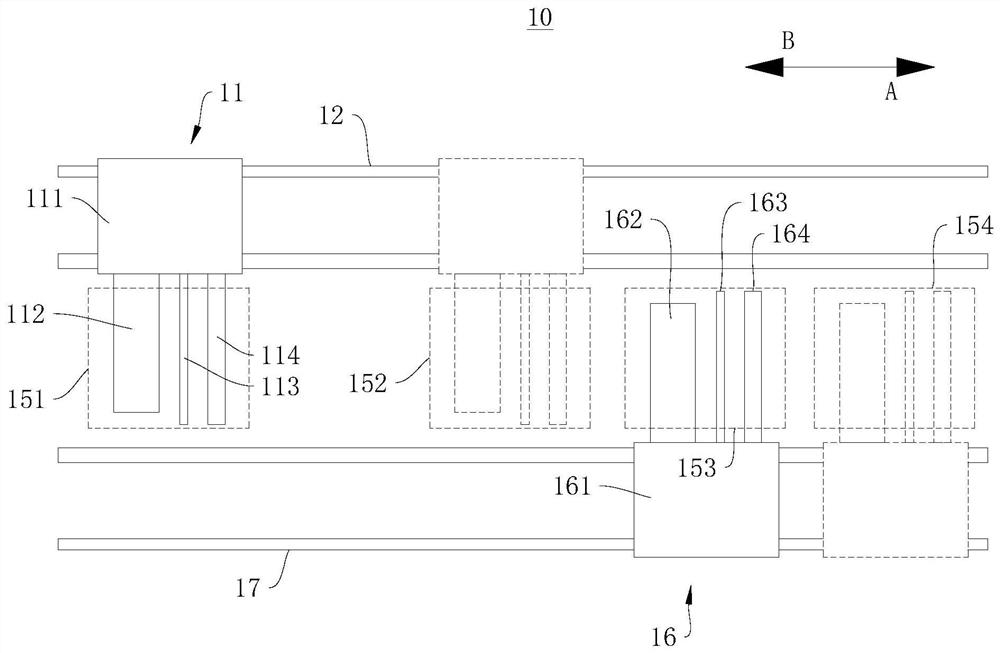

[0035] see figure 1 and figure 2 , figure 1 It is a schematic structural view of the battery continuous winding device 10 provided by the first embodiment of the present invention at a viewing angle. figure 2 It is a schematic structural diagram of the battery continuous winding device 10 provided by the first embodiment of the present invention from another viewing angle. exist figure 1 and figure 2 , the direction indicated by the arrow A is the first direction A, and the direction indicated by the arrow B is the second direction B.

[0036] The first embodiment of the present invention provides a battery continuous winding device 10, the battery continuous winding device 10 is used to wind the pole piece 910 and the diaphragm 920 to form a battery part 930, the battery continuous winding device 10 has the characteristics of high winding efficiency. The battery continuous winding device 10 can be applied to battery production equipment or battery production lines. ...

no. 2 example

[0069] see image 3 , image 3 It is a schematic flow chart of the battery continuous winding method provided by the second embodiment of the present invention.

[0070] The second embodiment of the present invention provides a continuous winding method for electric cores, and the continuous winding method for electric cores has the characteristics of high winding efficiency. The battery continuous winding method is applied to the battery continuous winding device 10 of the above-mentioned embodiment.

[0071] It should be noted that the basic principles and technical effects of the battery continuous winding method provided in this embodiment are the same as those of the above-mentioned embodiments. Corresponding content in the embodiment.

[0072] The battery continuous winding method, the battery continuous winding method includes:

[0073] Step S100: the first winding mechanism 11 and the second winding mechanism 16 alternately move to the winding station 153, and alte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com