Pipeline sludge cleaning robot

A robot and sludge technology, applied in motor vehicles, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of odorous pipes, narrow pipe space, and inability to discharge sewage smoothly, so as to improve work quality and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

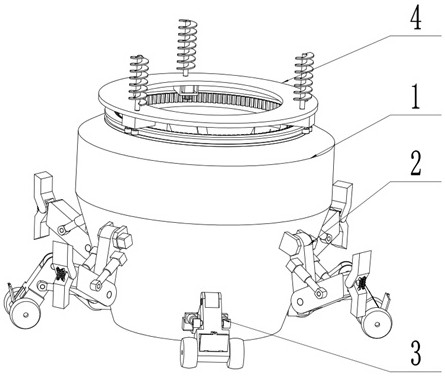

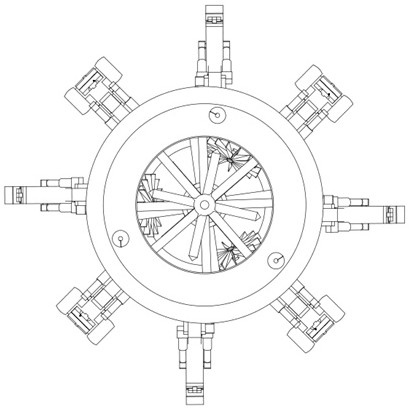

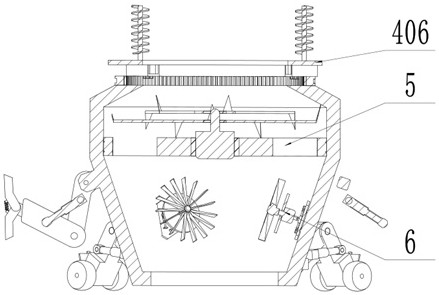

[0028] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 A pipeline sludge cleaning robot is shown, wherein the shell 1 is a cylindrical shell with a hollow interior, and is also used for the installation of the supporting mechanism 2, the walking mechanism 3, the stirring mechanism 4, the crushing structure 5, and the rotating mechanism 6. The platform is installed through different installation methods and 1.

[0029] The concrete structure of supporting mechanism 2 is as follows: Figure 4 As shown, the supporting hinge bearings 201 are equidistantly arranged in the middle of the outer surface of the housing 1, and there are four in this embodiment, and each supporting hinge bearing 201 is hinged with the rear end of the supporting upper arm 202, A supporting drive motor 203 is installed at its hinge, the front motor surface of the supporting driving motor 203 is fixedly installed on the supporting hinge sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com