Metal plate seam processing technology

A metal plate and processing technology, which is applied in the field of metal plate bite processing technology, can solve the problems of time-consuming installation and disassembly, poor use convenience, etc., and achieve the effects of convenient bite processing, good use effect and wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

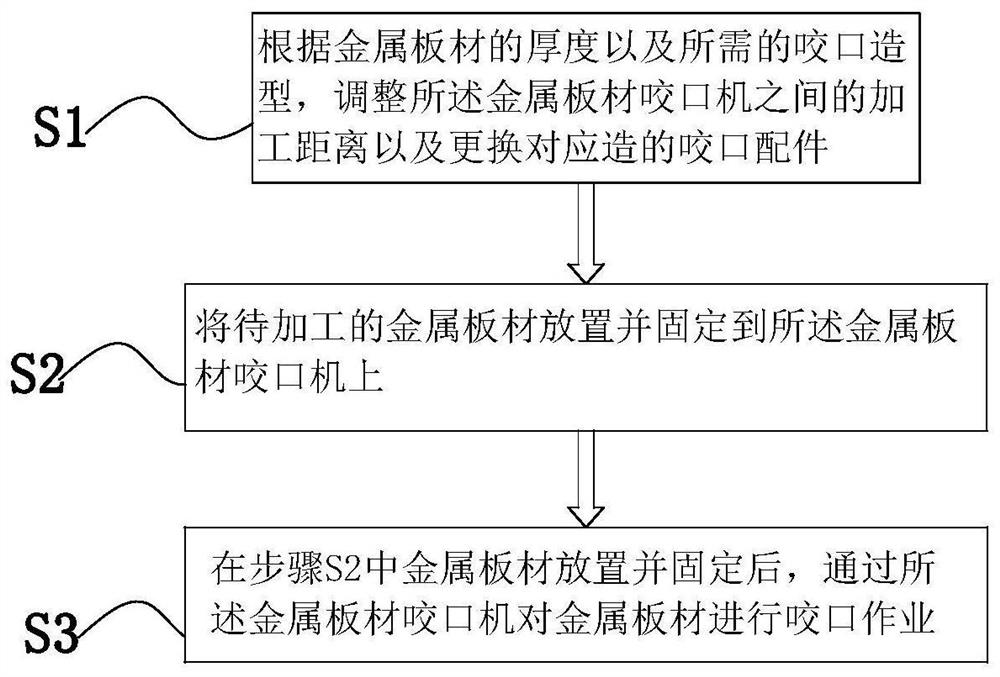

[0027] see Figure 1-Figure 7 , the present invention provides a technical solution: a metal plate bite processing process, which is mainly completed by a metal plate bite machine, and the metal plate bite processing process specifically includes the following steps:

[0028] S1. According to the thickness of the metal sheet and the required shape of the bite, adjust the processing distance between the sheet metal bite machines and replace the corresponding bite accessories;

[0029] S2, placing and fixing the metal plate to be processed on the metal plate biting machine;

[0030] S3. After the metal sheet is placed and fixed in step S2, the metal sheet is bitten by the metal sheet biting machine;

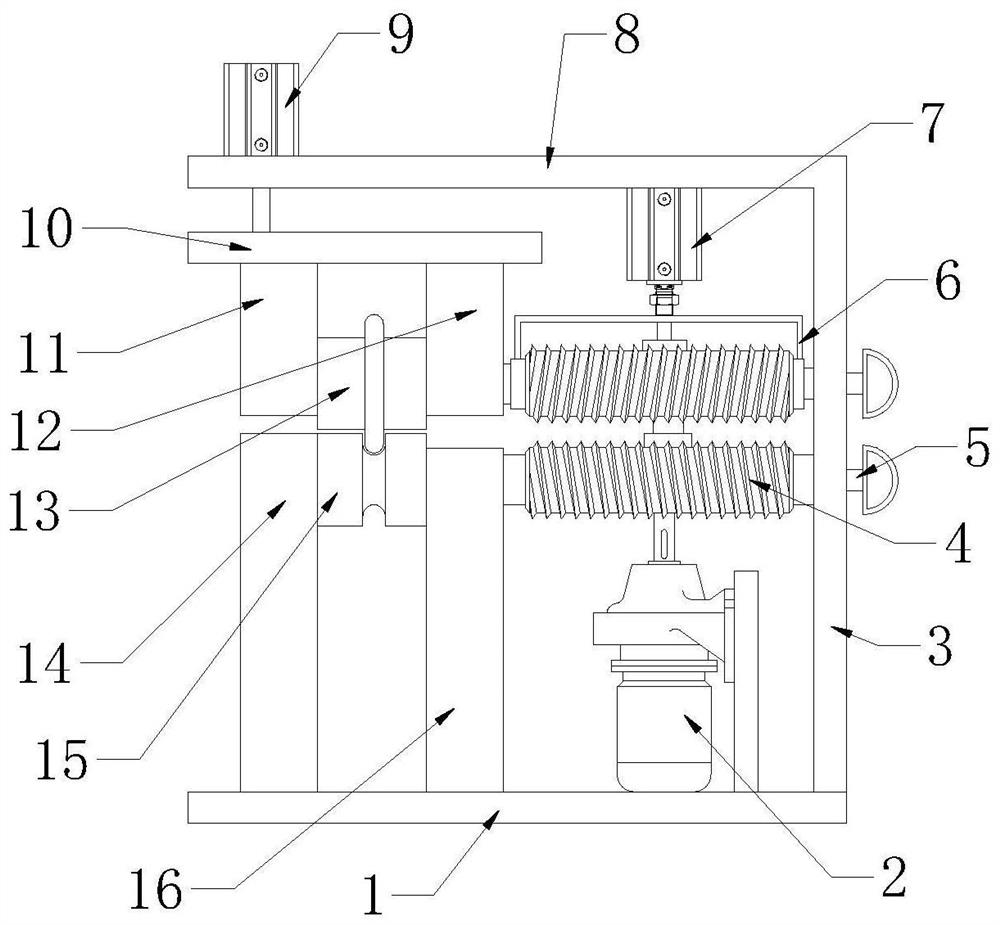

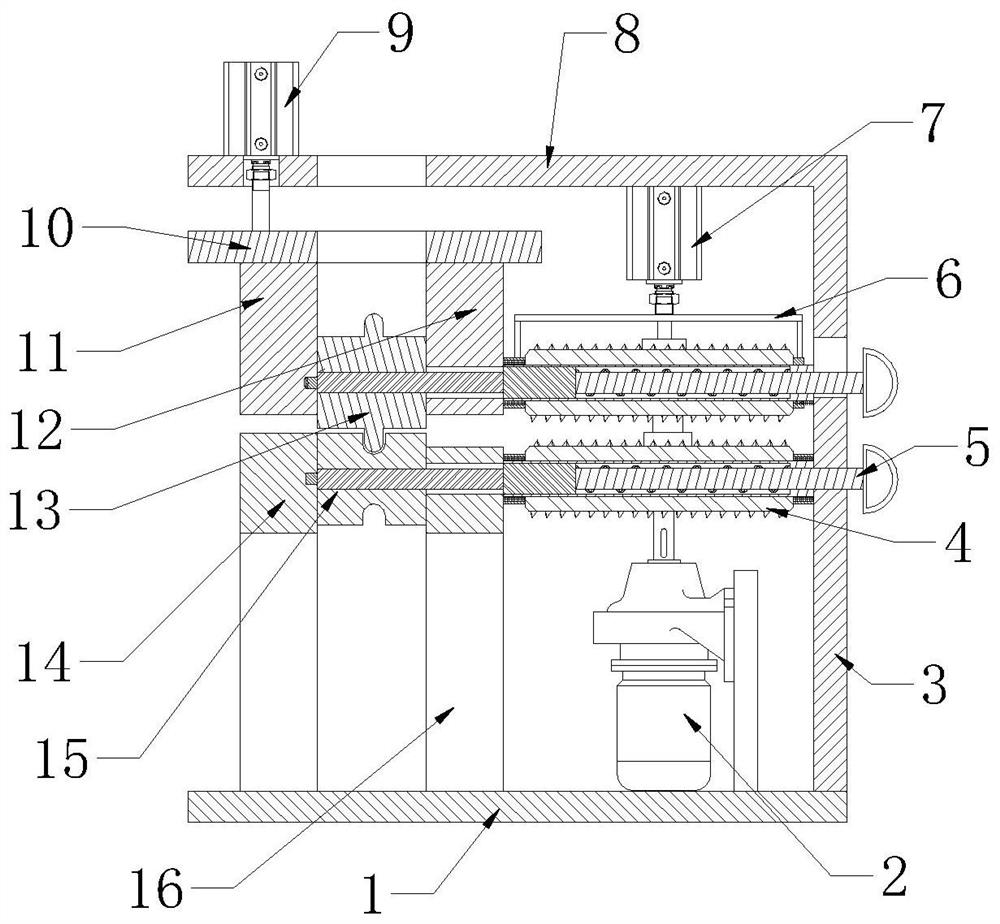

[0031] The sheet metal mouthing machine involv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com