A docking method for large compartments oriented to real-time monitoring

A real-time monitoring, cabin technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low quality consistency, cabin transfer, long preparation time, low efficiency, etc., to achieve realistic scenes and real-time updates The effect of docking details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

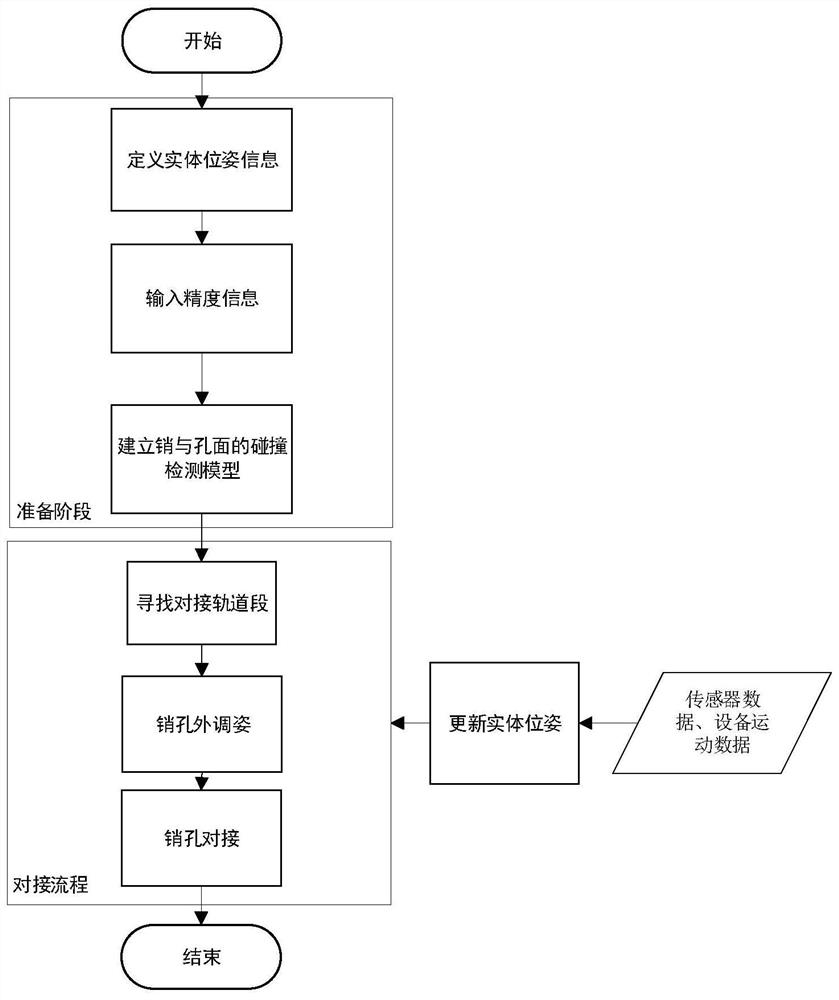

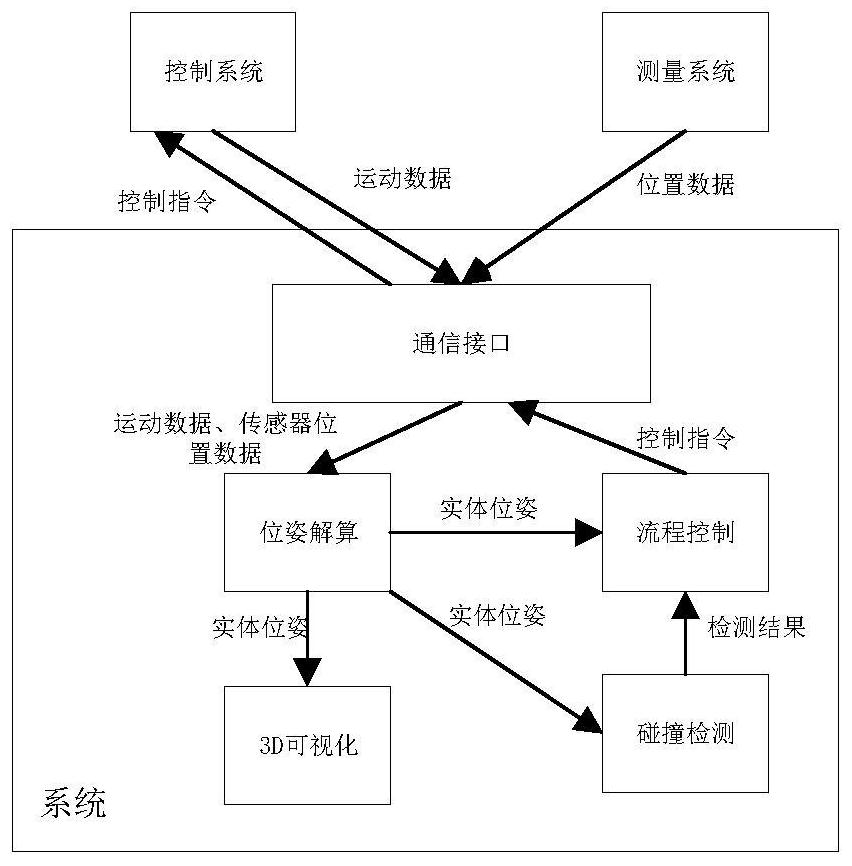

[0023]Such asfigure 2 As shown, this embodiment specifically includes the following steps:

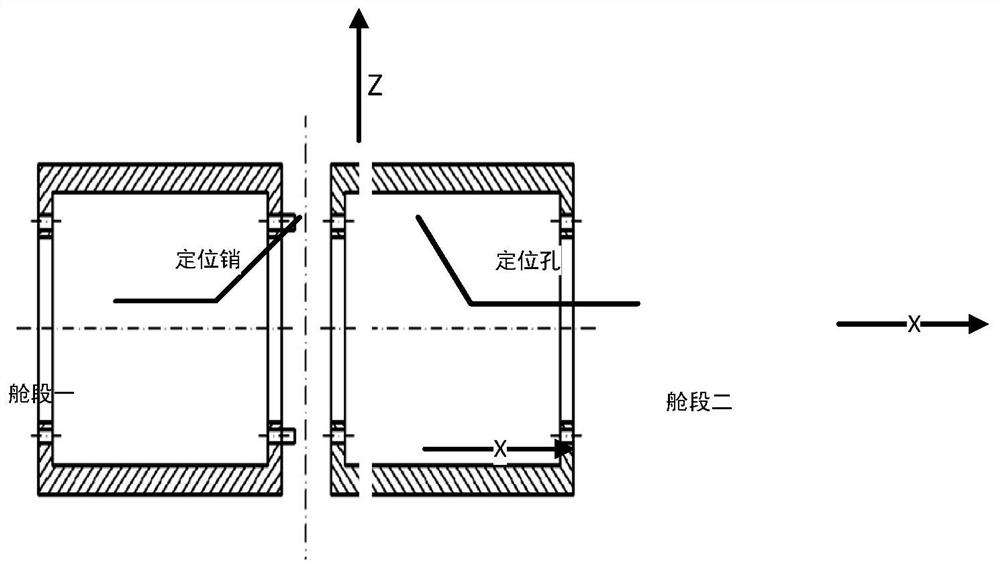

[0024]Step 1. Define the entity pose information, including the pose of the measuring tool in the measuring point coordinate system, the pose of the cabin under the measuring tool, the movement model of the pose adjustment equipment, and the ideal docking of the first cabin relative to the second cabin. ,Specifically:

[0025]1.1) Set the position sensor in the fixed coordinate system of each measuring tool (Ak} The coordinates under the coordinates are:{A1} Is the coordinate system of the first cabin measurement fixture, {A2} Is the fixed coordinate system of the measurement tooling for the second compartment. ToIs the X axis,Is the Z axis,The coordinate system of the measuring point that is the origin {Sk} In {AkThe pose in} isAssumethen:Measuring tool {Ak}In the measuring point coordinate system {Sk} The pose is

[0026]1.2) According to the survey tooling and cabin installation drawings, define t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com