Automatic tapping and positioning multifunctional drilling machine and accurate tapping method

A hole positioning and multi-functional technology, applied in the direction of drilling equipment and methods, automatic drilling control system, drilling equipment, etc., can solve the problems affecting the stability and safety of construction buildings, easy to make mistakes in opening holes, and poor adjustment accuracy In order to improve the accuracy of hole positioning and adjustment, reduce the difficulty of adjustment, and make it difficult to make mistakes in hole opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

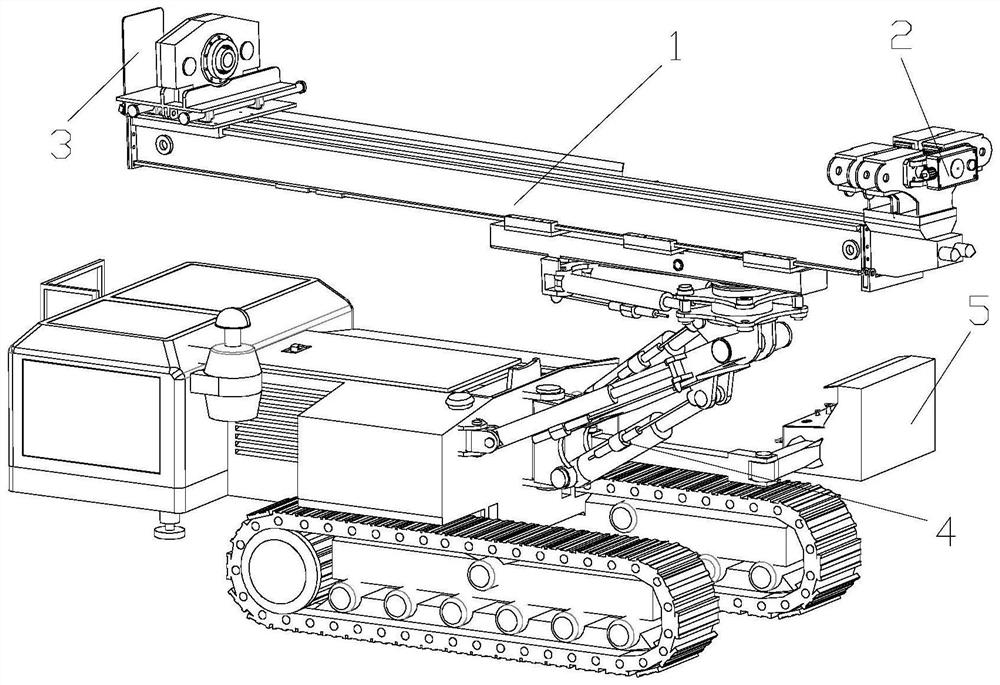

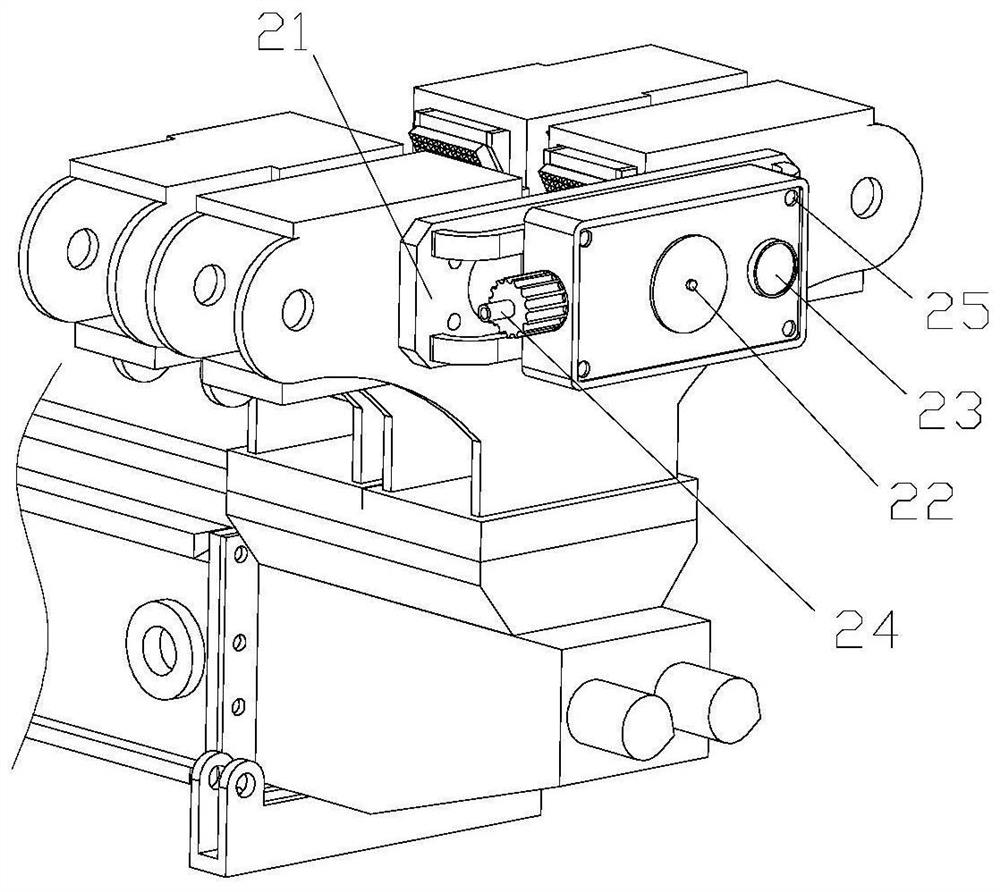

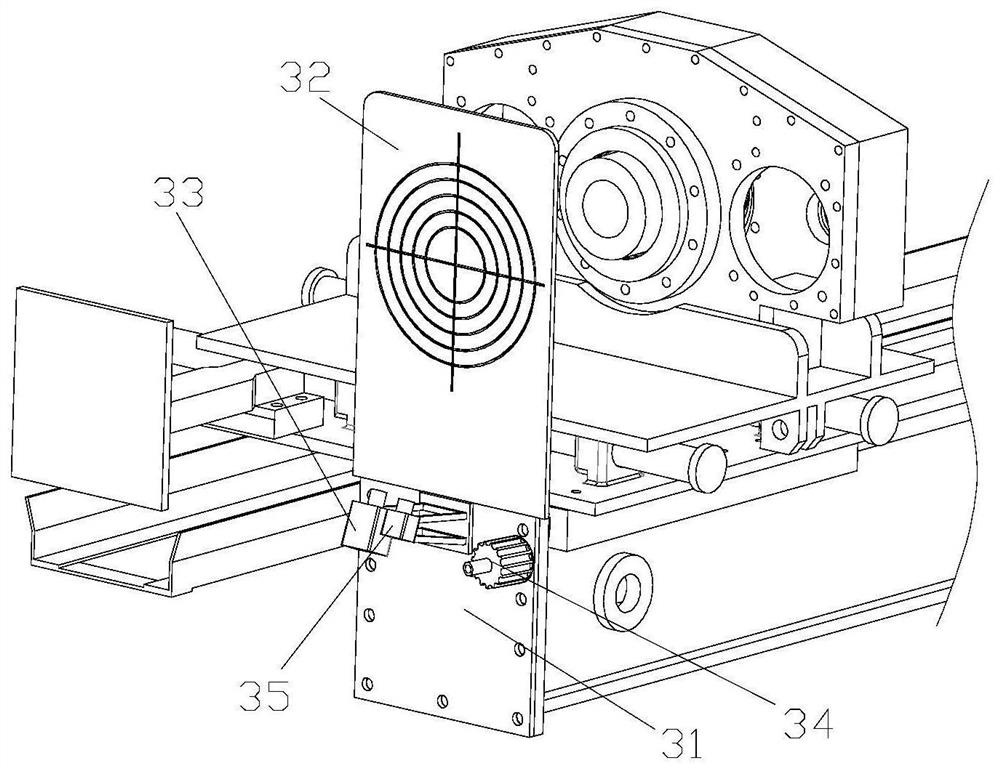

[0034] like Figure 1 to Figure 6 As shown, the present invention provides a multifunctional drilling rig for automatic drilling and positioning, which is used to cooperate with a laser total station for precise drilling, including a drilling rig body 1, a front-end measuring mechanism 2, a rear-end measuring mechanism 3, and a stroke measuring mechanism 4 And the central control mechanism 5; the front-end measuring mechanism 2 includes a laser emitter 22 coaxial with the drill pipe of the rig body 1, which is used to emit laser light towards the working surface and transmit the laser position information to the central control mechanism 5; the rear-end measuring mechanism 3 includes a target 32 installed coaxially with the drill pipe of the rig body 1, which is used to receive the laser irradiation of the target axis of the laser t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com