Mechanical component production equipment

A technology for producing equipment and parts, applied in the field of mechanized parts production equipment, can solve the problems of time-consuming and labor-intensive, and safety cannot be guaranteed, and achieve the effect of positioning, simple structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with accompanying drawing and specific embodiment:

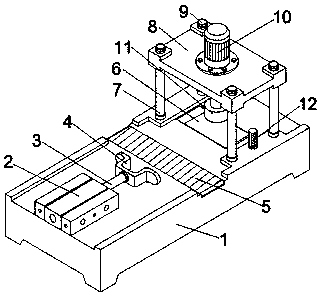

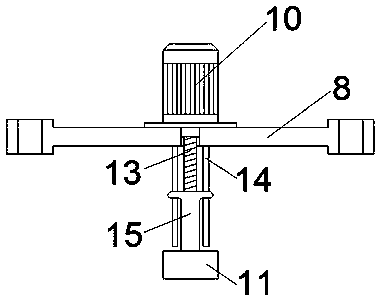

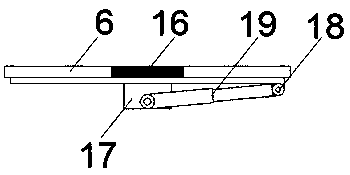

[0015] like Figure 1-3 As shown, a mechanized parts production equipment includes a workbench 1, a cylinder A2, a pneumatic push rod 3, a U-shaped fixing groove 4, a transmission feeding belt 5, an operating platform 6, a support column 7, a fixed top plate 8, and fixing bolts 9. Servo motor 10, briquetting block 11, cylinder A2 is installed on the front end of the top of the workbench 1, a pneumatic push rod 3 is installed on the front end of the cylinder A2, and a U-shaped fixing groove 4 is welded on the front end of the pneumatic push rod 3, so The top center of the workbench 1 is horizontally equipped with a transmission feeding belt 5, the top rear end of the workbench 1 is equipped with an operating platform 6, and the top rear end of the workbench 1 is respectively equipped with a fixed top plate 8 through four support columns 7, so The fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com