Automatic part machining device

A technology for processing devices and parts, applied in the field of automatic parts processing devices, can solve the problems of time-consuming, labor-intensive, and inability to guarantee safety, and achieve the effects of reliable posture adjustment, fast posture adjustment speed, and rapid positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

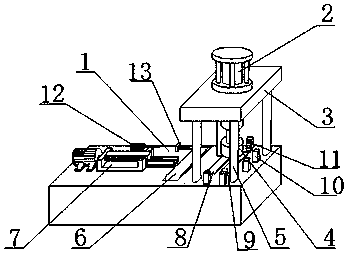

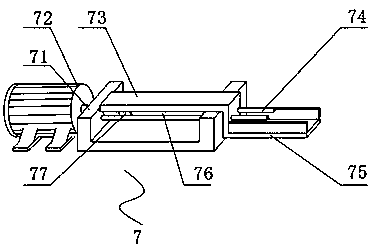

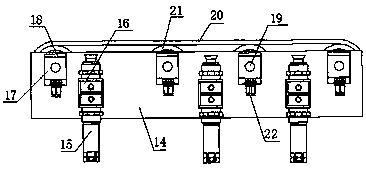

[0027] see Figure 1~4 , in an embodiment of the present invention, an automatic parts processing device includes a workbench 1, a pushing assembly 7, a workpiece conveying assembly, a limit assembly, an attitude adjustment assembly, a posture detection assembly, a pressing assembly and a processing machine, wherein , one side of the length direction of the workbench is provided with the pusher assembly 7, the pusher assembly is used to push the workpiece to the lower position of the pressing material fixing assembly; it is characterized in that,

[0028] A workpiece conveying assembly is provided on the width direction of the workbench, and the limit assembly is provided on one side of the workbench in the conveying direction of the workpiece conveying assembly, and the limit assembly is used for The position is limited so that the workpiece can be pushed to the position of the attitude adjustment component at the specified position;

[0029] The other side of the workbench ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com