Latch fastener structure on concrete wedge block casting mould

A technology for pouring molds and concrete, applied in the directions of molds, mold fixtures, mold auxiliary parts, etc., can solve problems such as easy loss, and achieve the effect of convenient combination and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

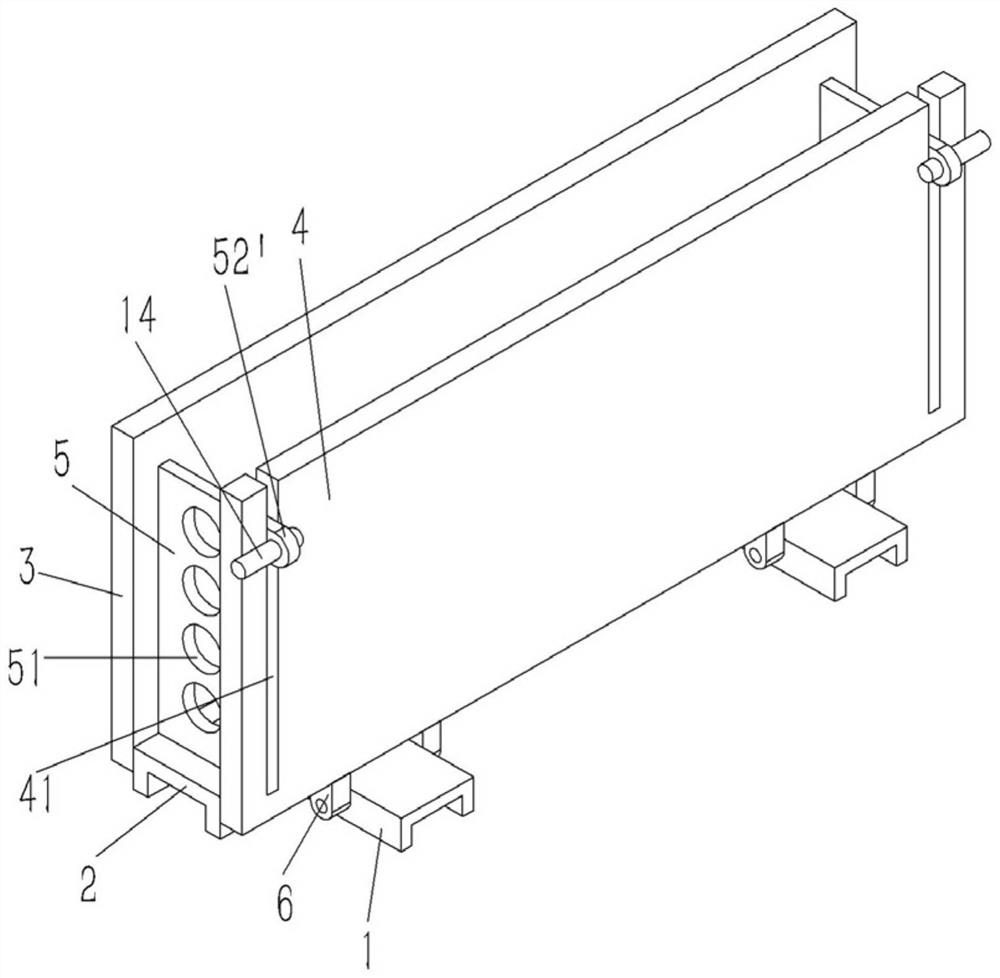

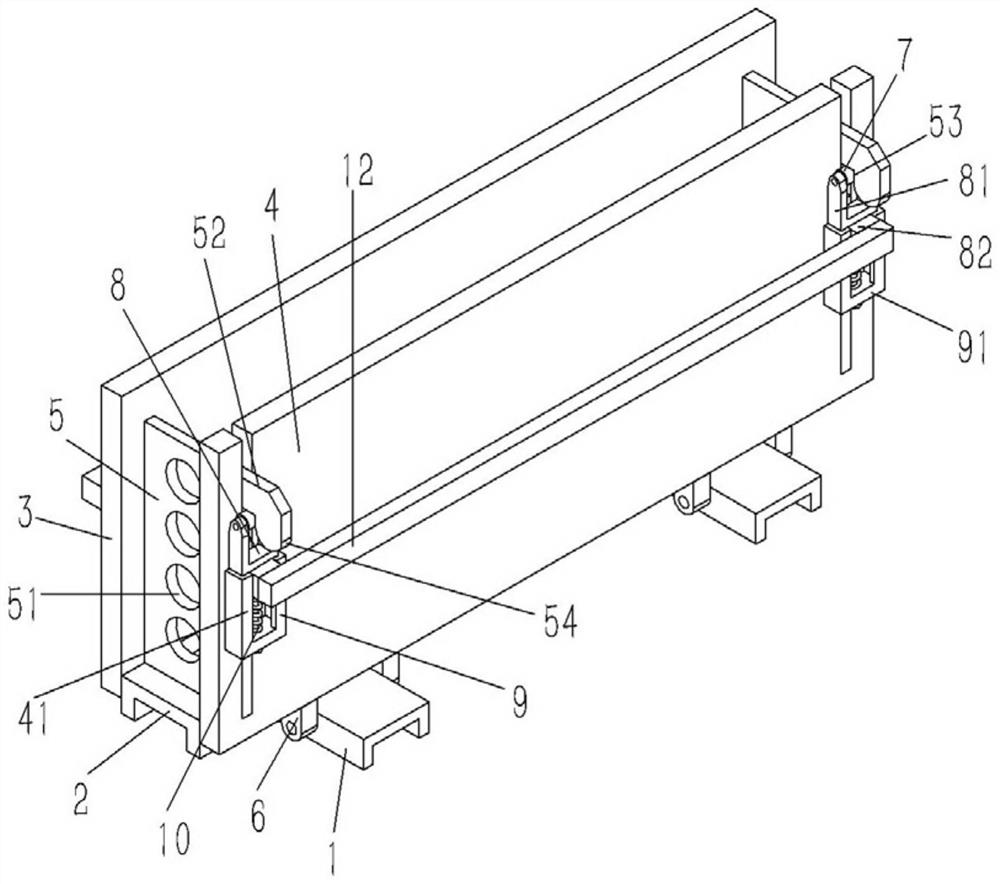

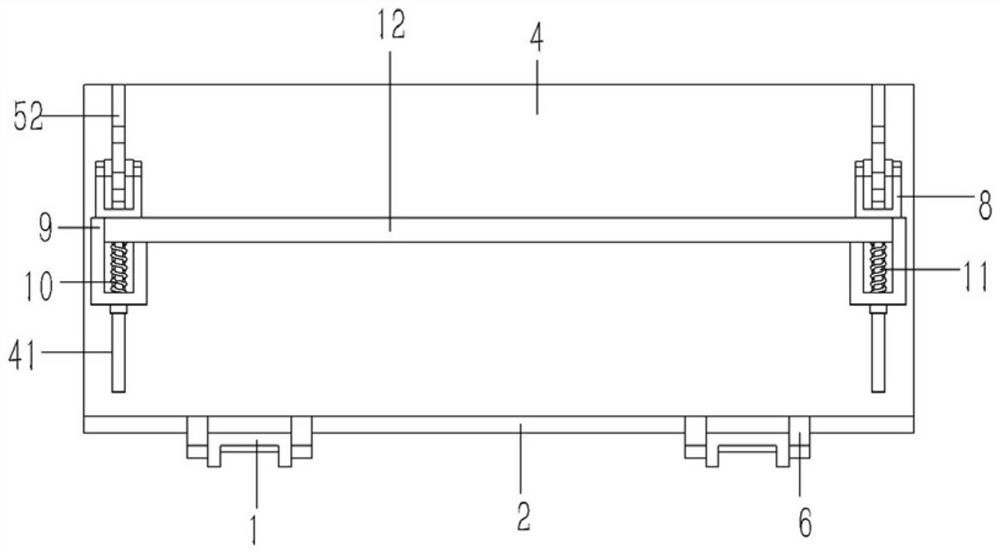

[0020] Example: see Figures 2 to 4 As shown, a locking structure on a concrete wedge pouring mold includes several horizontal support channel steels 1, the middle part of the support channel steel 1 is fixed with a longitudinal supporting plate 2, and the two sides of the supporting plate 2 are respectively provided with There are a left formwork 3 and a right formwork 4, and the lower end surfaces of the left formwork 3 and the right formwork 4 are fixed with hinge lugs 6, and the hinge lugs 6 are hinged with the supporting channel steel 2 through hinge shafts; Vertical slots 41 are formed at both ends, and a sealing baffle 5 is inserted into the slot 41. The sealing baffle 5 is fixed on the left template 3, and a support plate 52 is formed on the side wall of the upper end of the sealing baffle 5. The support plate The lower end surface of the 52 is formed with a vertical draw-in groove 53, and a pin shaft 7 is inserted in the draw-in slot 53. A slide block 8 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com