Large-tonnage load bearing device

A load-bearing, large-tonnage technology, applied in the mechanical field, can solve the problems of difficult test loading and the inability of the bearing device to meet the use requirements, and achieve the effect of broadening the bearing load range and expanding the diffusion area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

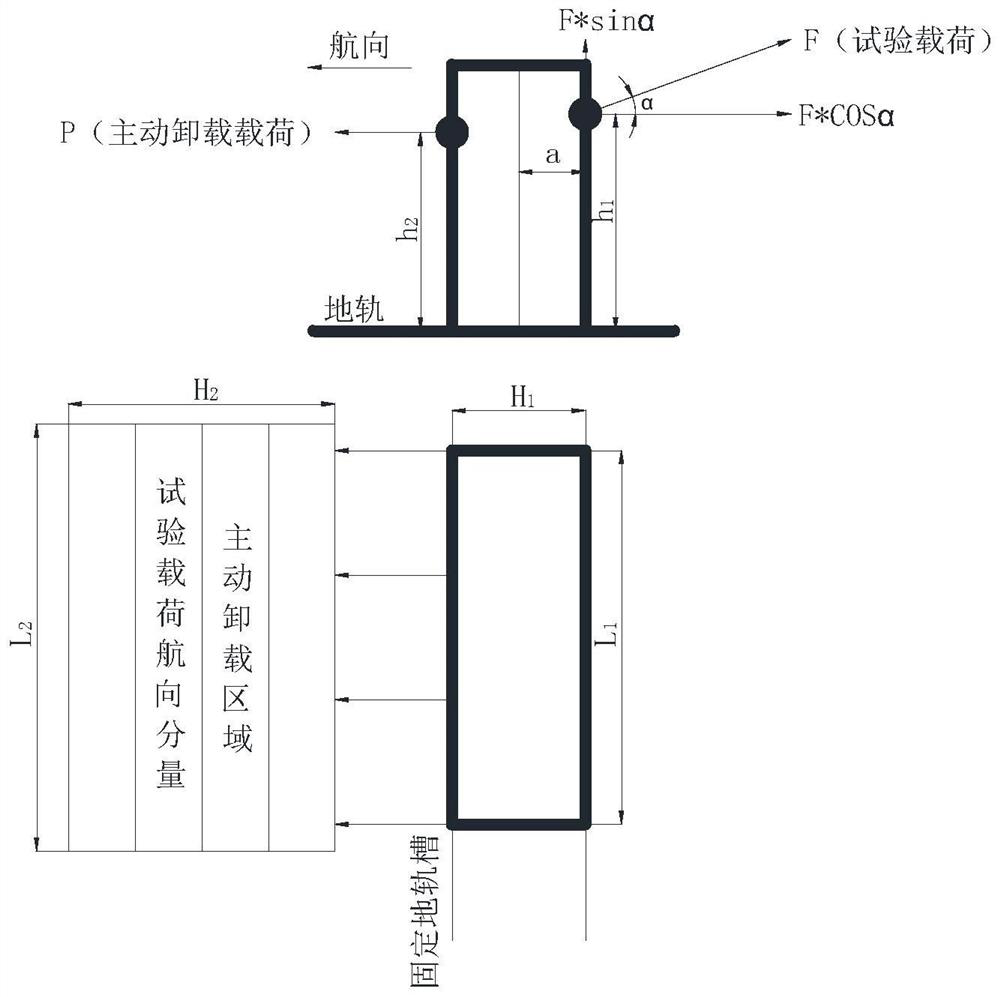

[0030] The purpose of the invention is to provide a large tonnage load bearing device. The device requires a compact and lightweight structure for easy transport and test installation; it requires strength and rigidity to meet certain requirements to ensure the safety and accuracy of the test. It is required to realize the active unloading of the directional component of the auxiliary take-off load and the floor diffusion of the vertical component to ensure the safety of the load-bearing floor and fixed equipment of the test plant.

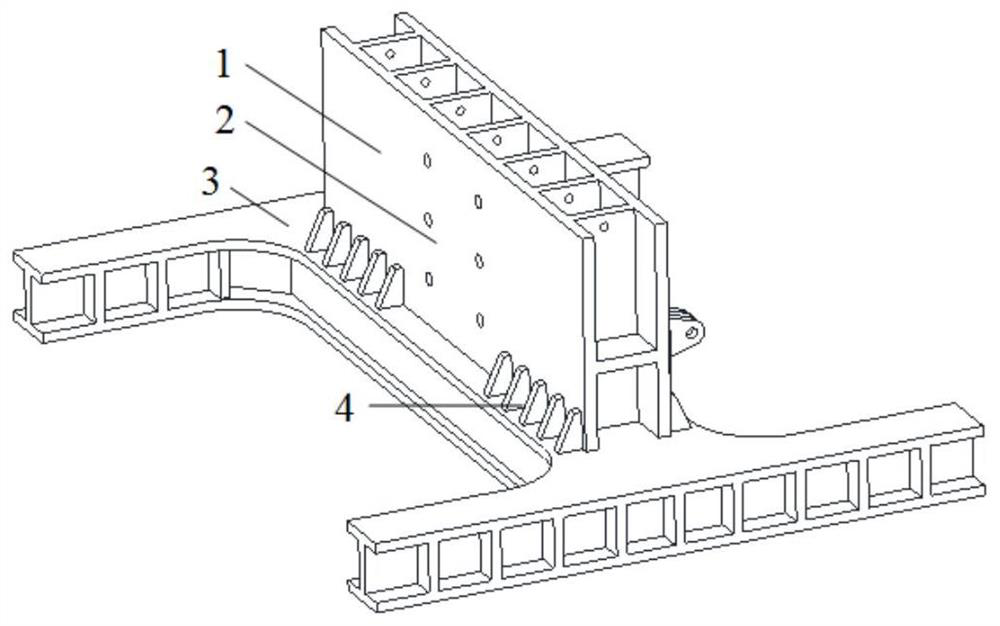

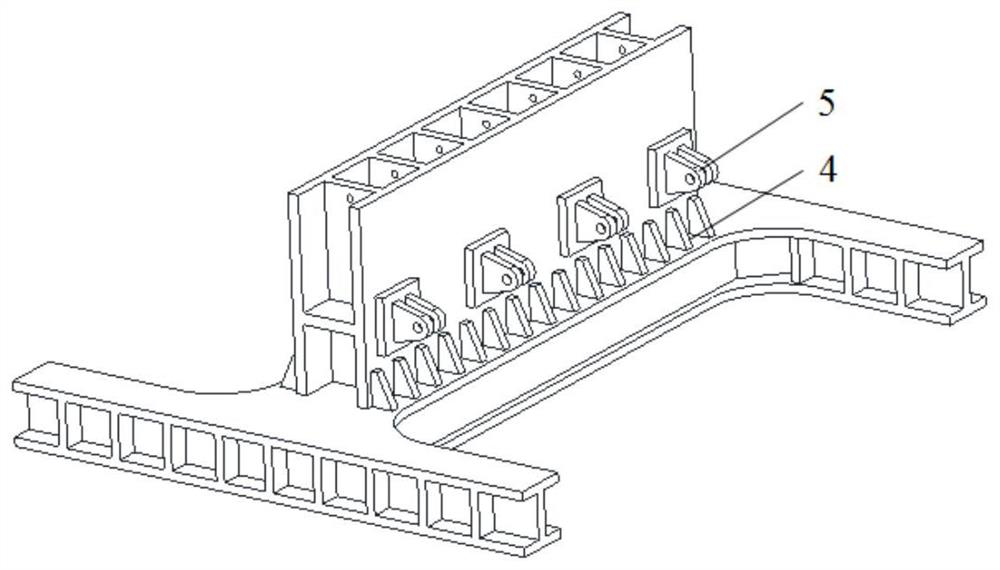

[0031] The invention is mainly realized by the following technical scheme: based on the characteristics of the auxiliary take-off test load of a new type of carrier-based aircraft, the large-tonnage load-carrying device adopts an integral welded structure of steel plates, and the integral welded structure is set for the course component of the test load Active unloading interface to safely unload the main course component of the test load to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com