Method and device for stepless speed regulation of fan in electromechanical system

A stepless speed regulation, electromechanical system technology, applied in mechanical equipment, machine/engine, cooling/ventilation/heating renovation, etc., can solve the problems of slow response, noise, easy to skip gears, etc., to achieve fast convergence and stable temperature control Precise, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

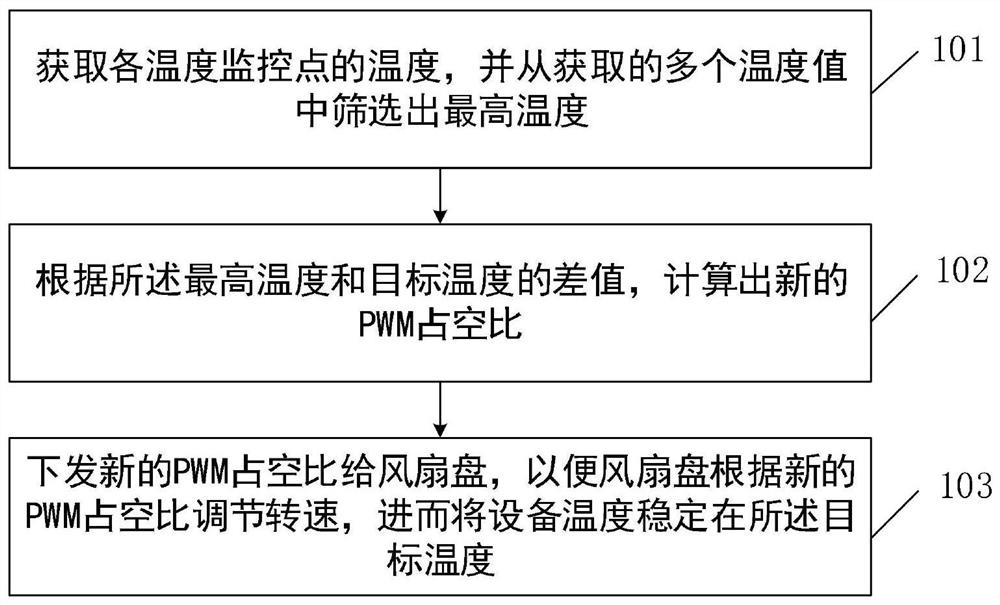

[0041] In order to solve the problems of slow speed convergence, slow response, easy shifting and serious noise in the traditional fan gear speed regulation, the embodiment of the present invention provides a stepless fan speed regulation method for electromechanical systems, such as figure 1 As shown, it mainly includes the following steps:

[0042] In step 101, the temperature of each temperature monitoring point is obtained, and the highest temperature is selected from the obtained multiple temperature values.

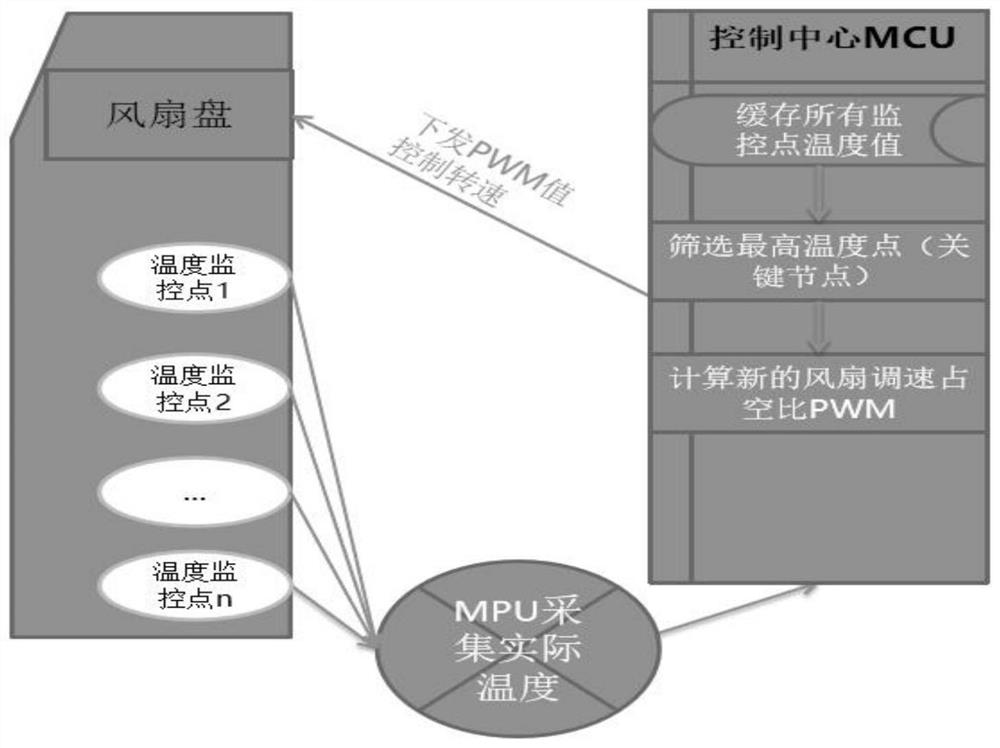

[0043] refer to figure 2 , there are usually multiple temperature monitoring points on the communication equipment, respectively recorded as temperature monitoring point 1, temperature monitoring point 2,..., temperature monitoring point n, respectively distributed in each business disk of the communication equipment or other motherboards that need heat dissipation on each processor; each temperature monitoring point is provided with a temperature sensor, and the ...

Embodiment 2

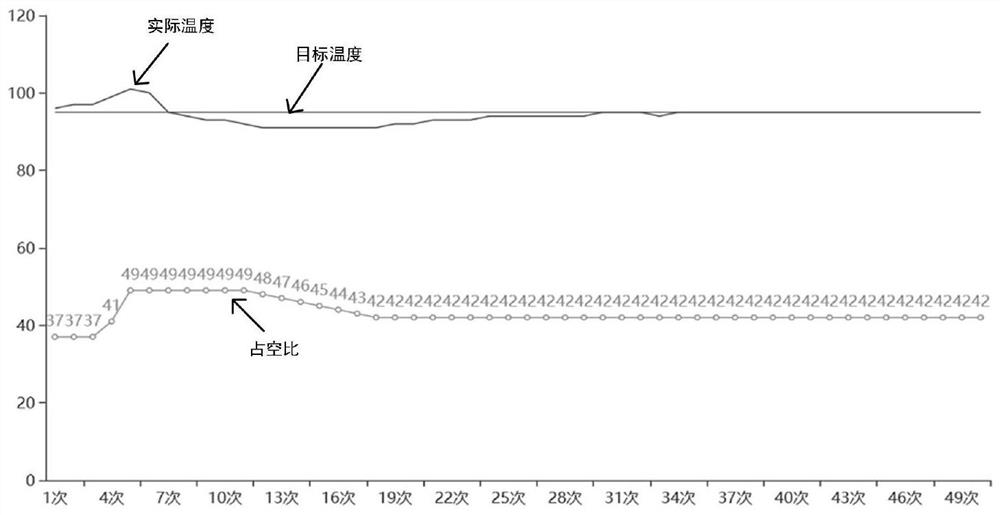

[0059] On the basis of the stepless speed regulation method for a fan of an electromechanical system provided in Embodiment 1 above, the embodiment of the present invention further describes the calculation formula of the PWM duty ratio in step 102 .

[0060] The calculation method of the PWM duty cycle specifically includes the following three situations:

[0061] 1) When delta_t>Tdiff and temp≥temp1, pwm=pwm1+C1*delta_t-C1*Tdiff;

[0062] 2) When delta_t<-Tdiff and temp≤temp1, pwm=pwm1+C2*delta_t+C2*Tdiff;

[0063] 3) In other cases, pwm=pwm1, that is, the duty cycle is not adjusted this time;

[0064] Among them, delta_t=temp-Tref. The meanings of the parameters in the above formula are as follows: Tref is the set target temperature, Tdiff is the maximum allowable deviation; temp is the maximum temperature during this monitoring, and temp1 is the temperature at the key node during the last speed regulation; pwm is the new PWM duty cycle calculated this time, pwm1 is the ...

Embodiment 3

[0082] On the basis of the stepless speed regulation method for the fan of the electromechanical system provided in the above-mentioned embodiment 1, the embodiment of the present invention further provides a stepless speed regulation device for the fan of the electromechanical system, which is used to implement the fan stepless speed regulation method in the first embodiment. Stepless speed regulation method.

[0083] like figure 2 As shown, the fan stepless speed regulation device provided by the embodiment of the present invention mainly includes the MPU, the MCU of the control center, the fan disk and a plurality of temperature sensors.

[0084] The plurality of temperature sensors are respectively arranged at a plurality of temperature monitoring points on the communication device, and are used to collect the temperature of each temperature monitoring point on the communication device;

[0085] The MPU is used to obtain the temperature collected by each temperature sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com